Thyristors Online | AmaSemiconductors Amandla Asezingeni Eliphezulu

IMIPHAKATHI YOMKHIQIZO

Incazelo

Uhlolojikelele lwe-Rectifier Diodes

Ama-Rectifier diode angamadivayisi e-semiconductor asetshenziswa ngokuyinhloko ukuguqula i-alternating current (AC) ku-direct current (DC). Zivumela i-current ukuthi igeleze kalula ibheke endaweni eyodwa ngenkathi iyivimba ibheke kolunye uhlangothi. Lesi sakhiwo esingaqondile sibenza babe izingxenye ezibalulekile ezintweni zamandla, ukucubungula isignali, kanye namasekethe e-elekthronikhi ahlukahlukene. Ama-diode okulungisa angakwazi ukuphatha ububanzi obuhlukahlukene bamaza nama-voltage, izenze zisebenziseke ngezindlela eziningi kuzinhlelo zokusebenza eziningi.

Izici ze-Rectifier Diodes

Unidirectional Conductivity: Ihambisa ukugeleza kwamanje ohlangothini olulodwa kuphela, ivimbe ngempumelelo i-reverse current.

Ukuphatha Kwamanje Okuphezulu: Idizayinelwe ukuthwala amaza okuya phambili amakhulu, ilungele izinhlelo zokusebenza zamandla aphezulu.

I-Peak Inverse Voltage (I-PIV): Ingakwazi ukumelana nama-voltage aphezulu ahlehlayo ngaphandle kokuwohloka.

I-Low Forward Voltage Drop: Yehlisa ukulahleka kwamandla njengokushisa, ngcono ukusebenza kahle.

Isikhathi Sokubuyisela Esisheshayo: Ngokushesha izinguquko zisuka ekwenzeni ziye ezifundeni ezingaqhubeki, kuzuzisa izinhlelo zokusebenza zemvamisa ephezulu.

Ukuzinza Okushisayo: Igcina ukusebenza ebangeni lokushisa elibanzi, ukuqinisekisa ukwethembeka ezimeni ezihlukahlukene.

Usayizi Ohlangene: Ifomu elincane lesici lisiza ukuhlanganiswa kumiklamo ye-electronic compact.

Kuqiza kahle: Ihlinzeka ngesixazululo esinomnotho sezidingo zokuguqulwa kwe-AC-to-DC.

Izinhlobonhlobo zamaphakheji: Itholakala ngezinketho zokupakisha eziningi ukuze ilingane nezidingo ezihlukene zokukhweza.

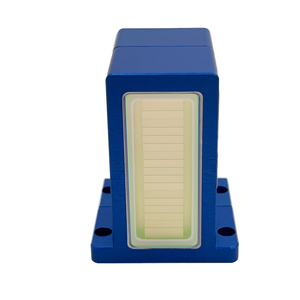

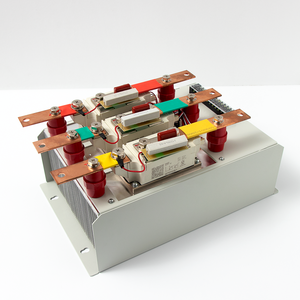

(400V welding machine rectifier diode for rectifier)

Specification of 400V welding machine rectifier diode for rectifier

This 400V welding device rectifier diode is a core part. It manages the critical job of transforming rotating current (UMSHINI ONGENISA UMOYA) right into straight present (DC). This DC current is necessary for secure, regulated welding arcs. The diode is built for requiring industrial settings. Its 400V ranking is vital. This voltage rating ensures it can hold up against the high reverse voltages typical in welding rectifiers. It avoids break down throughout procedure. These diodes manage extremely high electrical currents. They must maintain the hefty amperage needs of welding makers without failure. Heat generation is a major variable. These diodes create substantial heat under tons. Efficient warm dissipation is required. They are generally placed onto large, significant warmth sinks. These warmth sinks draw the warm far from the diode junction. Reliable cooling preserves performance. It stops premature failing. Ukuthembeka akuxoxiswana ekushiseleni. This diode provides constant efficiency cycle after cycle. It minimizes downtime. Upkeep prices stay reduced. The construction is robust. It makes use of resilient semiconductor materials. The product packaging is designed for high thermal stability. This ensures lengthy service life also under difficult conditions. Using this diode guarantees the rectifier operates properly. The welding maker delivers stable DC output. This leads to cleaner welds. Arc stability boosts considerably. Operators experience far better control. Total welding performance boosts. The diode’s requirements match the extensive requirements of professional welding equipment.

(400V welding machine rectifier diode for rectifier)

Applications of 400V welding machine rectifier diode for rectifier

400V welding machine rectifier diodes are crucial parts inside welding devices. They execute one important task. They transform alternating existing (I-AIR CONDITIONER) power right into straight present (DC) amandla. This DC power is required for stable, controlled welding arcs. These diodes deal with high voltage especially. The 400V rating implies they take care of the electric stress inside industrial welders safely. This stops damages. It makes sure trusted device procedure.

Industrial MIG welders make use of these diodes heavily. MIG welding needs smooth, consistent DC result. The diodes give this. They allow solid, clean welds on thick steel. Fabrication stores depend on this performance daily. TIG welding tools also depends upon these elements. Precise TIG arcs need steady DC current. The diodes deliver this security. This permits top notch welds on thinner materials like stainless-steel or light weight aluminum.

Stick welding equipments profit also. Excellent stick welding requires effective, steady DC output. The 400V diodes take care of the heavy electric loads. Construction websites and repair work usage stick welders typically. These diodes stand up to challenging conditions. They take care of heat. They take care of power surges. They handle continuous vibration. Their rugged layout makes them reliable.

Makers construct these diodes hard. They use materials like silicon. These materials deal with high temperatures well. Heat sinks are common. They draw excess heat away. This safeguards the diode. It expands its functioning life. Proper cooling is vital. Welding creates considerable warm inside. The diode should cope.

The 400V rating is essential. It matches common industrial power supplies. It makes sure compatibility. It offers safety and security margins. Voltage spikes happen throughout welding. The diode has to make it through these spikes. A 400V rating offers this defense. It protects against sudden diode failure. Device downtime is costly. Trusted diodes avoid this. They maintain production moving. They minimize repair work costs. Picking the right voltage diode issues. Utilizing a lower-rated diode threats disastrous failure. It takes the chance of harming the entire welding rectifier. The 400V diode is the safe, conventional selection for durable equipment.

Iphrofayela Yenkampani

Le nkampani PDDN Photoelectron Technology Co., Ltd., Ltd.(sales@pddn.com) ingelinye lamabhizinisi ahamba phambili kwezobuchwepheshe be-electronics kanye nemikhiqizo yamandla, ebandakanyeka ngokugcwele ekuthuthukiseni ama-solar inverters, ama-transformer, voltage regulators, amakhabethe wokusabalalisa, ama-thyristors, amamojula, ama-diode, izifudumezi, kanye nezinye izinto zikagesi noma ama-semiconductors. Sizozibophezela ekuhlinzekeni abasebenzisi ngekhwalithi ephezulu, imikhiqizo ephumelelayo kanye nenkonzo ecabangelayo.

Yamukela inkokhelo ngekhadi lesikweletu, T/T, I-West Union, kanye ne-Paypal. I-PDDN izothumela izimpahla kumakhasimende aphesheya kwezilwandle nge-FedEx, I-DHL, ngasolwandle, noma ngomoya. If you want high-quality 400V welding machine rectifier diode for rectifier, sicela usithumelele imibuzo; sizobe silapha ukuze sikusize.

Izindlela Zokukhokha

L/C, T/T, i-Western Union, I-Paypal, Ikhadi lesikweletu njll.

Ukuthunyelwa

Ngasolwandle, ngomoya, nge-express, njengoba amakhasimende ecela.

Izimo Zokugcina

1) Gcina endaweni eyomile ekamelweni lokushisa.

2) Gwema umswakama kanye nezinga lokushisa eliphezulu.

3) Sebenzisa ngokushesha ngemva kokuvula isikhwama sokupakisha sangaphakathi.

5 FAQs of 400V welding machine rectifier diode for rectifier

Nazi 5 FAQs about 400V welding machine rectifier diodes:

What does the rectifier diode do? It changes AC power into DC power. Welding arcs need stable DC current. The diode makes this happen. It acts like a one-way valve for electricity.

How do I know if a diode fails? Look for obvious damage first. Burnt marks or cracks are bad signs. The welding arc might become weak or unstable. You might see sparks inside the machine. The machine could overheat fast. Output might drop completely. Check diodes with a multimeter if possible.

Can I replace just one diode? Usually not. Diodes work together in a set called a bridge. If one fails, others often get damaged too. Replace the whole rectifier assembly. This is safer. It prevents more problems later. Check the manufacturer’s advice.

Are all 400V diodes the same? Cha. Voltage rating is crucial. Use 400V or higher. Izilinganiso zamanje nazo zibalulekile. It must match your machine’s output. Physical size and mounting style differ. Get the exact replacement part. Using the wrong diode causes failure.

How long do these diodes last? It depends heavily on use. Normal conditions give years of service. Heavy use or overloads shorten life. Poor cooling kills diodes fast. Electrical surges are bad. Good maintenance helps. Keep the machine clean. Ensure cooling fans work. Avoid pushing the machine too hard.

(400V welding machine rectifier diode for rectifier)

CELA I-QUOTE

IMIKHIQIZO EHLOBANE

DF20NA160 DF30NA160 Bridge Rectifier 5-SIP Electronic components module

Rectifier SEW BG 1.5 8253846 high quality and cheap

new arrived original Rectifier diode module DSE12X101-06A

New And 100% Origail Rectifier Module DPR-4850-D-DCE

Rectifier unit 6SE7033-8EE85-0AA0 in Stock