Thyristors Online | High-Quality Power Semiconductor

MGA PARAMETER NG PRODUKTO

Paglalarawan

Pangkalahatang-ideya ng Rectifier Diodes

Ang rectifier diodes ay mga semiconductor device na pangunahing ginagamit para sa pag-convert ng alternating current (AC) sa direktang kasalukuyang (DC). Pinapayagan nilang madaling dumaloy ang kasalukuyang sa isang direksyon habang hinaharangan ito sa kabilang direksyon. Ang unidirectional property na ito ay ginagawa silang mahahalagang bahagi sa mga power supply, pagpoproseso ng signal, at iba't ibang mga electronic circuit. Ang mga diode ng rectifier ay maaaring hawakan ang isang malawak na hanay ng mga alon at boltahe, ginagawa itong maraming nalalaman para sa maraming aplikasyon.

Mga Tampok ng Rectifier Diodes

Unidirectional Conductivity: Pinapadali ang kasalukuyang daloy sa isang direksyon lamang, epektibong hinaharangan ang reverse current.

Mataas na Kasalukuyang Paghawak: Dinisenyo upang magdala ng malaking pasulong na alon, angkop para sa mga high-power na application.

Peak Inverse Voltage (PIV): Maaaring makatiis ng mataas na reverse voltages nang hindi nasisira.

Low Forward Voltage Drop: Pinaliit ang pagkawala ng enerhiya bilang init, pagpapabuti ng kahusayan.

Mabilis na Oras ng Pagbawi: Mabilis na lumipat mula sa pagsasagawa patungo sa hindi pagsasagawa ng mga estado, kapaki-pakinabang para sa mga high-frequency na aplikasyon.

Thermal Stability: Pinapanatili ang pagganap sa isang malawak na hanay ng temperatura, pagtiyak ng pagiging maaasahan sa iba't ibang mga kondisyon.

Compact na Sukat: Ang maliit na form factor ay nagpapadali sa pagsasama sa mga compact na electronic na disenyo.

Cost-Effective: Nagbibigay ng matipid na solusyon para sa AC-to-DC na mga pangangailangan sa conversion.

Iba't-ibang mga Package: Magagamit sa maraming mga pagpipilian sa packaging upang magkasya sa iba't ibang mga kinakailangan sa pag-mount.

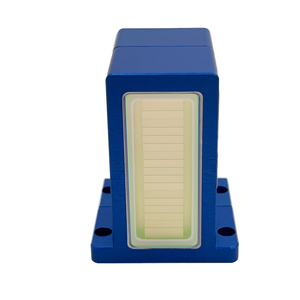

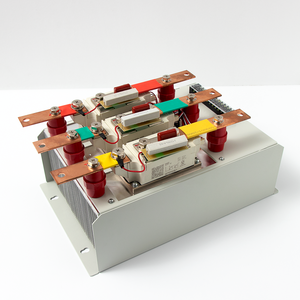

(400V welding machine rectifier diode for rectifier)

Specification of 400V welding machine rectifier diode for rectifier

This 400V welding device rectifier diode is a core part. It manages the critical job of transforming rotating current (AIR CONDITIONING) right into straight present (DC). This DC current is necessary for secure, regulated welding arcs. The diode is built for requiring industrial settings. Its 400V ranking is vital. This voltage rating ensures it can hold up against the high reverse voltages typical in welding rectifiers. It avoids break down throughout procedure. These diodes manage extremely high electrical currents. They must maintain the hefty amperage needs of welding makers without failure. Heat generation is a major variable. These diodes create substantial heat under tons. Efficient warm dissipation is required. They are generally placed onto large, significant warmth sinks. These warmth sinks draw the warm far from the diode junction. Reliable cooling preserves performance. It stops premature failing. Ang pagiging maaasahan ay hindi mapag-usapan sa hinang. This diode provides constant efficiency cycle after cycle. It minimizes downtime. Upkeep prices stay reduced. Matibay ang konstruksyon. It makes use of resilient semiconductor materials. The product packaging is designed for high thermal stability. This ensures lengthy service life also under difficult conditions. Using this diode guarantees the rectifier operates properly. The welding maker delivers stable DC output. This leads to cleaner welds. Arc stability boosts considerably. Operators experience far better control. Total welding performance boosts. The diode’s requirements match the extensive requirements of professional welding equipment.

(400V welding machine rectifier diode for rectifier)

Applications of 400V welding machine rectifier diode for rectifier

400V welding machine rectifier diodes are crucial parts inside welding devices. They execute one important task. They transform alternating existing (AIR CONDITIONER) power right into straight present (DC) kapangyarihan. This DC power is required for stable, controlled welding arcs. These diodes deal with high voltage especially. The 400V rating implies they take care of the electric stress inside industrial welders safely. This stops damages. It makes sure trusted device procedure.

Industrial MIG welders make use of these diodes heavily. MIG welding needs smooth, consistent DC result. The diodes give this. They allow solid, clean welds on thick steel. Fabrication stores depend on this performance daily. TIG welding tools also depends upon these elements. Precise TIG arcs need steady DC current. The diodes deliver this security. This permits top notch welds on thinner materials like stainless-steel or light weight aluminum.

Stick welding equipments profit also. Excellent stick welding requires effective, steady DC output. The 400V diodes take care of the heavy electric loads. Construction websites and repair work usage stick welders typically. These diodes stand up to challenging conditions. They take care of heat. They take care of power surges. They handle continuous vibration. Their rugged layout makes them reliable.

Makers construct these diodes hard. They use materials like silicon. These materials deal with high temperatures well. Heat sinks are common. They draw excess heat away. This safeguards the diode. It expands its functioning life. Proper cooling is vital. Welding creates considerable warm inside. The diode should cope.

The 400V rating is essential. It matches common industrial power supplies. It makes sure compatibility. It offers safety and security margins. Voltage spikes happen throughout welding. The diode has to make it through these spikes. A 400V rating offers this defense. It protects against sudden diode failure. Device downtime is costly. Trusted diodes avoid this. They maintain production moving. They minimize repair work costs. Picking the right voltage diode issues. Utilizing a lower-rated diode threats disastrous failure. It takes the chance of harming the entire welding rectifier. The 400V diode is the safe, conventional selection for durable equipment.

Profile ng Kumpanya

Ang PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) ay isa sa mga nangungunang negosyo sa power electronics technology at power products, na ganap na kasangkot sa pagbuo ng mga solar inverters, mga transformer, mga regulator ng boltahe, mga kabinet ng pamamahagi, thyristors, mga module, mga diode, mga pampainit, at iba pang mga elektronikong kagamitan o semiconductor. Kami ay magiging nakatuon sa pagbibigay sa mga user ng mataas na kalidad, mahusay na mga produkto at mapagbigay na serbisyo.

Tumatanggap ito ng bayad sa pamamagitan ng Credit Card, T/T, West Union, at Paypal. Ipapadala ng PDDN ang mga kalakal sa mga customer sa ibang bansa sa pamamagitan ng FedEx, DHL, sa pamamagitan ng dagat, o sa pamamagitan ng hangin. If you want high-quality 400V welding machine rectifier diode for rectifier, mangyaring magpadala sa amin ng mga katanungan; nandito kami para tulungan ka.

Mga Paraan ng Pagbabayad

L/C, T/T, Western Union, Paypal, Credit Card atbp.

Pagpapadala

Sa pamamagitan ng dagat, sa pamamagitan ng hangin, sa pamamagitan ng express, bilang kahilingan ng mga customer.

Mga Kondisyon sa Imbakan

1) Mag-imbak sa isang tuyo na kapaligiran sa temperatura ng silid.

2) Iwasan ang basa at mataas na temperatura.

3) Gamitin kaagad pagkatapos buksan ang panloob na packing bag.

5 FAQs of 400V welding machine rectifier diode for rectifier

Narito ang 5 FAQs about 400V welding machine rectifier diodes:

What does the rectifier diode do? It changes AC power into DC power. Welding arcs need stable DC current. The diode makes this happen. It acts like a one-way valve for electricity.

How do I know if a diode fails? Look for obvious damage first. Burnt marks or cracks are bad signs. The welding arc might become weak or unstable. You might see sparks inside the machine. The machine could overheat fast. Output might drop completely. Check diodes with a multimeter if possible.

Can I replace just one diode? Usually not. Diodes work together in a set called a bridge. If one fails, others often get damaged too. Replace the whole rectifier assembly. This is safer. It prevents more problems later. Check the manufacturer’s advice.

Are all 400V diodes the same? Hindi. Voltage rating is crucial. Use 400V or higher. Current rating matters too. It must match your machine’s output. Physical size and mounting style differ. Get the exact replacement part. Using the wrong diode causes failure.

Gaano katagal ang mga diode na ito? It depends heavily on use. Normal conditions give years of service. Heavy use or overloads shorten life. Poor cooling kills diodes fast. Electrical surges are bad. Good maintenance helps. Keep the machine clean. Ensure cooling fans work. Avoid pushing the machine too hard.

(400V welding machine rectifier diode for rectifier)

HUMILING NG QUOTE

MGA KAUGNAY NA PRODUKTO

auto reverse rectifier 30A para sa wastewater treatment

DF30AA160 – Original Bridge Rectifiers IC Chip integrated circuit compon electron bom SMT PCBA service

GP26089184 rectifier bridge rectifiers

R-6 Rectifier Diode 20A10 20A 1000V Diode

Rectifier diode RS2050 SOT23-6 2050