Thyristors Online | Gjysmëpërçues me fuqi të cilësisë së lartë

PARAMETRAT E PRODUKTIT

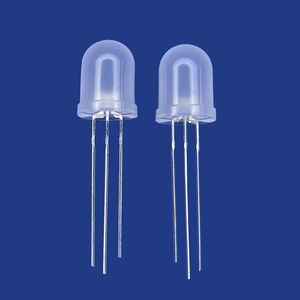

Përshkrimi

Pasqyrë e diodave ndreqës

Diodat ndreqës janë pajisje gjysmëpërçuese që përdoren kryesisht për konvertimin e rrymës alternative (AC) në rrymë të vazhdueshme (DC). Ato lejojnë që rryma të rrjedhë lehtësisht në një drejtim ndërsa e bllokojnë atë në drejtim të kundërt. Kjo veti e njëanshme i bën ato komponentë thelbësorë në furnizimin me energji elektrike, përpunimi i sinjalit, dhe qarqe të ndryshme elektronike. Diodat ndreqës mund të përballojnë një gamë të gjerë rrymash dhe tensionesh, duke i bërë ato të gjithanshme për aplikime të shumta.

Karakteristikat e diodave ndreqës

Përçueshmëri njëdrejtimëshe: Lehtëson rrjedhën e rrymës vetëm në një drejtim, duke bllokuar në mënyrë efektive rrymën e kundërt.

Trajtimi i rrymës së lartë: Projektuar për të bartur rryma të konsiderueshme përpara, i përshtatshëm për aplikime me fuqi të lartë.

Tensioni i anasjelltë i pikut (PIV): Mund të përballojë tensione të larta të kundërta pa u prishur.

Rënie e ulët e tensionit përpara: Minimizon humbjen e energjisë si nxehtësi, përmirësimin e efikasitetit.

Koha e Shpejtë e Rimëkëmbjes: Kalon shpejt nga gjendjet përcjellëse në jopërçuese, e dobishme për aplikime me frekuencë të lartë.

Stabiliteti termik: Ruan performancën në një gamë të gjerë temperaturash, sigurimi i besueshmërisë në kushte të ndryshme.

Madhësi kompakte: Faktori i formës së vogël lehtëson integrimin në dizajne kompakte elektronike.

Me kosto efektive: Ofron një zgjidhje ekonomike për nevojat e konvertimit AC-në-DC.

Shumëllojshmëri paketash: I disponueshëm në opsione të shumta paketimi për t'iu përshtatur kërkesave të ndryshme të montimit.

(bridge rectifier for brake motor)

Specification of bridge rectifier for brake motor

A bridge rectifier transforms rotating present (AC) ndaj rrymës së vazhduar (DC). This feature is essential for brake electric motors. Brake electric motors require secure DC power to trigger electromagnetic brakes. The rectifier guarantees smooth motor procedure by preserving constant stopping performance. Trick requirements identify the rectifier’s suitability for particular motor applications. Voltage scores are key. The input voltage have to match the electric motor’s AC supply. Typical ranges consist of 100V to 500V AIR CONDITIONER. Output voltage depends upon the rectifier’s design. A full-wave bridge setup generally provides greater effectiveness. Current capability is just as crucial. The rectifier has to deal with the electric motor’s maximum current without overheating. Standard designs sustain 1A to 30A. Picking a greater existing rating than called for enhances sturdiness. Thermal management issues. Warmth sinks or built-in cooling devices stop part failure. Operating temperature arrays from -40 ° C deri në 125 ° C makes sure integrity in harsh settings. Materials made use of in building and construction influence efficiency. Aluminum housings use lightweight resilience. Shielded substrates lower electric leak. Security accreditations are non-negotiable. Compliance with UL, CE, or RoHS requirements guarantees top quality. Placing alternatives differ. Screw terminals simplify setup. PCB-mounted versions match compact layouts. Reverse voltage defense prevents damage from inaccurate circuitry. Surge tolerance is essential. The rectifier must stand up to short-term voltage spikes without breakdown. Efficiency scores over 95% decrease power loss. Reduced ahead voltage decline minimizes heat generation. Packaging has to withstand dampness and dust. IP-rated units are perfect for industrial settings. Checking under load conditions confirms real-world performance. Customization choices consist of flexible output voltages. Compatibility with single-phase or three-phase systems broadens application extent. Maintenance demands are reduced. Regular examination of links guarantees long-term functionality. Appropriate sizing avoids straining. Speak with maker datasheets for precise requirements. Bridge rectifiers for brake electric motors focus on reliability. They make sure continuous electric motor stopping. Right option equilibriums price and efficiency. Always validate compatibility with the motor’s electrical criteria.

(bridge rectifier for brake motor)

Applications of bridge rectifier for brake motor

Bridge rectifiers play a crucial role in brake electric motor systems. They convert alternating current (AC) për të drejtuar rrymën (DC). This conversion is necessary for brake motors to work correctly. Brake motors depend on electro-magnetic brakes to quit quickly. These brakes need a stable DC power supply. Bridge rectifiers give this by changing the air conditioning input from the power source right into DC outcome. The procedure makes sure the brake involves efficiently and dependably.

Industrial machinery commonly makes use of brake motors with bridge rectifiers. Conveyor belts are a common instance. They must stop promptly to prevent accidents or product damage. The rectifier assures the brake obtains constant DC power. This enables the motor to halt the belt immediately. Elevator systems additionally rely on these parts. Sudden stops are critical for traveler safety. The rectifier ensures the brake activates instantly when required.

Bridge rectifiers improve efficiency in brake electric motor applications. They minimize power loss throughout AC-to-DC conversion. This maintains the system running colder. Overheating dangers decrease. The design of bridge rectifiers sustains compact electric motor setups. Space-saving is necessary in devices like CNC devices or robotics. Smaller sized components indicate simpler assimilation right into limited rooms.

Resilience matters in rough atmospheres. Bridge rectifiers manage high voltage and existing degrees. They hold up against vibrations and temperature level adjustments usual in factories. This integrity reduces maintenance requirements. Downtime decreases. Assembly line stay operational much longer.

Brake electric motors in automobile manufacturing use bridge rectifiers. Setting up robots call for exact stopping during jobs. The rectifier supplies steady DC power for consistent brake performance. Mistakes in positioning parts are avoided. Product quality remains high.

Bridge rectifiers also enhance security. Without trusted DC power, brakes could fail. Devices could malfunction. The rectifier serves as a safeguard. It ensures the brake engages whenever. Workers operate equipment with confidence.

Personalization options exist for various brake electric motor setups. Rectifiers are available in numerous sizes and power ratings. They match details voltage needs. Compatibility with different motor types is ensured. Upgrading existing systems ends up being straightforward.

Profili i Kompanisë

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) është një nga ndërmarrjet kryesore në teknologjinë elektronike të energjisë dhe produktet e energjisë, e cila është plotësisht e përfshirë në zhvillimin e inverterëve diellorë, transformatorëve, rregullatorët e tensionit, kabinete shperndarese, tiristorët, modulet, diodat, ngrohje, dhe pajisje të tjera elektronike ose gjysmëpërçues. Ne do të angazhohemi t'u ofrojmë përdoruesve cilësi të lartë, produkte efikase dhe shërbim i vëmendshëm.

Ai pranon pagesa me kartë krediti, T/T, West Union, dhe Paypal. PDDN do t'i dërgojë mallrat klientëve jashtë shtetit përmes FedEx, DHL, nga deti, ose me ajër. If you want high-quality bridge rectifier for brake motor, ju lutemi na dërgoni pyetje; ne do të jemi këtu për t'ju ndihmuar.

Metodat e pagesës

L/C, T/T, Western Union, Paypal, Karta e Kreditit etj.

Dërgesë

Nga deti, nga ajri, me shprehje, sipas kërkesës së klientëve.

Kushtet e ruajtjes

1) Ruani në një mjedis të thatë në temperaturën e dhomës.

2) Shmangni lagështinë dhe temperaturën e lartë.

3) Përdoreni menjëherë pas hapjes së qeses së brendshme të paketimit.

5 FAQs of bridge rectifier for brake motor

A bridge rectifier changes AC to DC power. Brake motors need steady DC power to work right. The rectifier makes sure the motor’s brake gets stable DC voltage. This stops the brake from slipping or failing. Without it, the motor might not stop safely.

People ask why bridge rectifiers are used in brake motors. Brake systems need DC power to hold the motor still when it’s off. AC power alone can’t do this. The rectifier fixes the AC power into DC. This keeps the brake engaged until the motor starts again.

People wonder how to pick the right bridge rectifier. Check the motor’s voltage and current needs. Match the rectifier’s voltage rating to the motor’s AC supply. Make sure the current rating is higher than the motor’s max load. This stops overheating. A higher-rated rectifier lasts longer.

People ask how to install a bridge rectifier. Connect the AC input terminals to the motor’s power supply. Link the DC output terminals to the brake coil. Double-check the wiring matches the diagram. Wrong connections damage the rectifier or brake. Test the system slowly after installing.

People worry about common problems. No output voltage means the rectifier might be broken. Check for burnt parts or loose wires. Low voltage could mean a failing diode. Overheating happens if the rectifier is too small for the load. Always use a rectifier with enough capacity. Keep it cool and clean.

(bridge rectifier for brake motor)