Tyristory online | Vysokokvalitné výkonové polovodiče

PARAMETRE PRODUKTU

Popis

Prehľad usmerňovacích diód

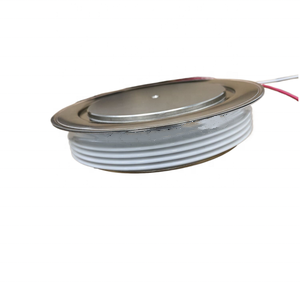

Usmerňovacie diódy sú polovodičové zariadenia používané predovšetkým na premenu striedavého prúdu (AC) do jednosmerného prúdu (DC). Umožňujú ľahký tok prúdu v jednom smere a blokujú ho v opačnom smere. Táto jednosmerná vlastnosť z nich robí základné komponenty v napájacích zdrojoch, spracovanie signálu, a rôzne elektronické obvody. Usmerňovacie diódy dokážu zvládnuť široký rozsah prúdov a napätí, vďaka čomu sú univerzálne pre mnohé aplikácie.

Vlastnosti usmerňovacích diód

Jednosmerná vodivosť: Uľahčuje tok prúdu iba v jednom smere, efektívne blokuje spätný prúd.

Manipulácia s vysokým prúdom: Navrhnuté na prenášanie značných dopredných prúdov, vhodné pre aplikácie s vysokým výkonom.

Špičkové inverzné napätie (PIV): Vydrží vysoké spätné napätie bez toho, aby sa pokazil.

Nízky pokles napätia vpred: Minimalizuje straty energie vo forme tepla, zlepšenie efektívnosti.

Rýchla doba zotavenia: Rýchly prechod z vodivých do nevodivých stavov, užitočné pre vysokofrekvenčné aplikácie.

Tepelná stabilita: Udržuje výkon v širokom rozsahu teplôt, zabezpečenie spoľahlivosti v rôznych podmienkach.

Kompaktná veľkosť: Malý tvarový faktor uľahčuje integráciu do kompaktných elektronických dizajnov.

Nákladovo efektívne: Poskytuje ekonomické riešenie pre potreby konverzie AC-na-DC.

Rôzne balíčky: Dostupné vo viacerých variantoch balenia, aby vyhovovali rôznym požiadavkám na montáž.

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)

Specification of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This 12V 1500A high power electroplating rectifier provides severe existing for demanding plating jobs. It gives a stable 12 volts DC result. The system takes care of approximately 1500 amps continually. Air air conditioning keeps everything running cool also under hefty lots. Followers draw air over interior parts. This design stays clear of overheating throughout lengthy plating cycles. Upkeep stays straightforward without fluid coolant systems.

An integrated timing feature is a significant advantage. Operators established specific plating durations straight on the device. The rectifier immediately turns off after the set time. This makes certain regular layer thickness each time. It stops over-plating blunders. Workers do not require to constantly view the clock. Productivity improves significantly.

The rectifier supplies uncomplicated procedure. Controls are clear and easy to use. Readjust voltage and present setups with easy handles or switches. Review outputs on clear digital displays. Establishing the timer is just as basic. New customers learn it rapidly. Arrangement calls for very little training.

Safety and integrity are core features. The design includes defense against overloads and brief circuits. This safeguards both the tools and the plating bath. The system utilizes robust industrial-grade components. These parts stand up to rough plating store atmospheres. The steel unit withstands rust. It likewise protects against dirt and dampness ingress. Electric safety accreditations are standard.

This power supply fits massive electroplating procedures. It deals with huge parts or high-volume barrel layering effectively. The high amperage guarantees quick deposition rates. Constant outcomes minimize product waste. The timing function includes vital process control. Manufacturing facilities see far better throughput and reduced costs.

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)

Applications of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This effective 12V 1500A electroplating rectifier delivers serious power for demanding commercial procedures. Poskytuje stabilný, high-current DC outcome vital for constant metal deposition. The incorporated timing function is a major benefit. Operators set exact plating periods for each batch. This automation guarantees repeatable results batch after batch. It eliminates uncertainty. It boosts product consistency substantially.

Air cooling maintains the system running reliably under hefty tons. Followers dissipate warmth efficiently. This layout avoids intricate liquid cooling systems. Upkeep stays easier. Prestoje sa znižujú. The robust construction takes care of challenging factory settings. It stands up to warmth, špina, and vibration common in layering stores.

This rectifier masters high-throughput electroplating applications. It’s excellent for plating big surface areas promptly. Think auto components, heavy machinery components, or large steel fixtures. The high 1500A capacity handles thick down payments successfully. It matches difficult chromium plating, nickel plating, and copper plating procedures requiring significant power. The secure outcome keeps consistent present density. This leads to attire, high-grade metal coverings.

The timer feature automates the plating cycle. Employees load components. They begin the process. The device competes the set time. It then turns off instantly. This avoids over-plating. It conserves power. It optimizes bathroom life. It releases operators for other tasks. Accuracy timing makes sure every part gets exactly the appropriate layer density.

Integrity is crucial in production. This air-cooled design uses reliable operation. Regular DC result protects against layer problems. Integrated defense circuits guard against overloads and shorts. This shields your important workpieces. It safeguards the rectifier itself. The unit gives the muscle needed for industrial-scale electroplating. Its timing feature adds crucial procedure control.

Profil spoločnosti

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) je jedným z popredných podnikov v oblasti technológie výkonovej elektroniky a energetických produktov, ktorá sa plne podieľa na vývoji solárnych invertorov, transformátory, regulátory napätia, rozvodné skrine, tyristory, modulov, diódy, ohrievače, a iné elektronické zariadenia alebo polovodiče. Zaviazali sme sa poskytovať používateľom vysokú kvalitu, efektívne produkty a ohľaduplný servis.

Prijíma platby prostredníctvom kreditnej karty, T/T, West Union, a Paypal. PDDN doručí tovar zákazníkom do zámoria prostredníctvom FedEx, DHL, po mori, alebo letecky. If you want high-quality 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier, pošlite nám prosím otázky; budeme tu, aby sme vám pomohli.

Spôsoby platby

L/C, T/T, Western Union, Paypal, Kreditná karta atď.

Zásielka

Po mori, letecky, expresne, ako zákazníci požadujú.

Podmienky skladovania

1) Skladujte v suchom prostredí pri izbovej teplote.

2) Vyhnite sa vlhkosti a vysokej teplote.

3) Spotrebujte ihneď po otvorení vnútorného baliaceho vrecka.

5 FAQs of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

What is this rectifier used for? This rectifier powers industrial electroplating and electrolysis. It delivers stable DC power. Factories use it for metal coating tasks. It handles chrome, nikel, zinc plating. It manages heavy-duty operations smoothly. It fits large-scale production needs.

Aké sú kľúčové vlastnosti? It supplies 12 voltov a 1500 zosilňovače. This offers robust power for demanding jobs. It includes a built-in timing function. This controls process duration precisely. It uses air cooling technology. Air cooling simplifies the setup. It avoids water-based systems entirely. This reduces maintenance efforts. It ensures long-term reliability. It saves factory floor space too.

How does the timing function work? Set the desired time upfront. Choose hours, minút, or seconds. The unit runs for that exact period. It shuts down automatically afterward. This guarantees uniform plating results. It minimizes energy waste. It removes timing mistakes. Workers handle other duties during operation.

Why choose air cooling? Air cooling relies on internal fans. Fans circulate air through the machine. This dissipates heat effectively. It beats water cooling in simplicity. No plumbing or water supply is necessary. It cuts operational expenses. It performs in arid or gritty environments. It resists freezing in cold climates. It provides consistent cooling always.

What safety measures are included? Multiple safeguards are integrated. Overload protection interrupts power during excessive current. Short-circuit protection responds instantly to faults. Over-temperature protection switches off the unit if overheated. These features prevent equipment damage. They shield workers from harm. The design prioritizes workplace safety. The construction ensures durability.

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)