Thyristors آن لائن | اعلي معيار پاور سيمڪنڊڪٽرز

پراڊڪٽ پيٽرولر

وصف

Rectifier Diodes جو جائزو

ريڪٽيفير ڊاءِڊس سيمي ڪنڊڪٽر ڊوائيسز آهن جيڪي بنيادي طور تي متبادل ڪرنٽ کي تبديل ڪرڻ لاءِ استعمال ٿين ٿيون (اي سي) سڌي موجوده ۾ (ڊي سي). اهي ڪرنٽ کي آساني سان وهڻ جي اجازت ڏين ٿا هڪ طرف ۾ جڏهن ته ان کي مخالف سمت ۾ روڪي ٿو. هي unidirectional ملڪيت انهن کي بجلي جي فراهمي ۾ ضروري اجزاء بڻائي ٿو, سگنل پروسيسنگ, ۽ مختلف اليڪٽرانڪ سرڪٽس. Rectifier diodes واء ۽ وولٹیجز جي وڏين رينج کي سنڀالي سگھن ٿا, انهن کي ڪيترن ئي ايپليڪيشنن لاءِ ورسٽائل ٺاهڻ.

Rectifier Diodes جون خاصيتون

اڻ سڌي چالڪ: صرف هڪ طرفي ۾ موجوده وهڪري کي آسان بڻائي ٿو, مؤثر طريقي سان ريورس ڪرنٽ کي بلاڪ ڪرڻ.

اعلي موجوده سنڀال: ڪافي اڳتي وڌڻ لاء ٺهيل, اعلي طاقت جي ايپليڪيشنن لاء مناسب.

چوٽي Inverse voltage (PIV): بغير ٽوڙڻ جي اعلي ريورس وولٽز کي برداشت ڪري سگھي ٿو.

گھٽ فارورڊ وولٽيج ڊراپ: گرمي جي طور تي توانائي جي نقصان کي گھٽائي ٿو, ڪارڪردگي بهتر ڪرڻ.

تيز بحالي وقت: تيزيءَ سان هلائڻ کان وٺي غير هلائڻ واري رياستن ڏانهن, اعلي تعدد ايپليڪيشنن لاءِ فائديمند.

حرارتي استحڪام: هڪ وسيع درجه حرارت جي حد تائين ڪارڪردگي برقرار رکي ٿي, مختلف حالتن ۾ اعتماد کي يقيني بڻائي.

ڪمپيڪٽ سائيز: ننڍو فارم فيڪٽر کمپیکٹ اليڪٽرانڪ ڊيزائن ۾ انضمام کي آسان بڻائي ٿو.

مُله تي اثرائتو: AC-to-DC تبادلي جي ضرورتن لاءِ اقتصادي حل فراهم ڪري ٿي.

مختلف قسم جا پيڪيج: ڪيترن ئي پيڪنگنگ جي اختيارن ۾ موجود مختلف چڙهڻ گهرجن کي پورو ڪرڻ لاءِ.

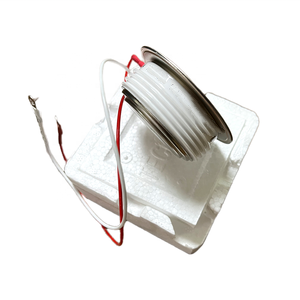

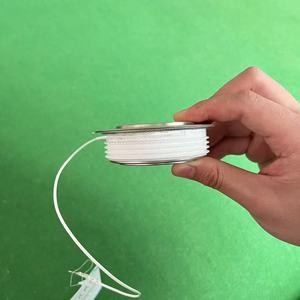

(bridge rectifier for brake motor)

Specification of bridge rectifier for brake motor

A bridge rectifier transforms rotating present (اي سي) موجوده کي سڌو ڪرڻ لاء (ڊي سي). This feature is essential for brake electric motors. Brake electric motors require secure DC power to trigger electromagnetic brakes. The rectifier guarantees smooth motor procedure by preserving constant stopping performance. Trick requirements identify the rectifier’s suitability for particular motor applications. Voltage scores are key. The input voltage have to match the electric motor’s AC supply. Typical ranges consist of 100V to 500V AIR CONDITIONER. Output voltage depends upon the rectifier’s design. A full-wave bridge setup generally provides greater effectiveness. Current capability is just as crucial. The rectifier has to deal with the electric motor’s maximum current without overheating. Standard designs sustain 1A to 30A. Picking a greater existing rating than called for enhances sturdiness. Thermal management issues. Warmth sinks or built-in cooling devices stop part failure. Operating temperature arrays from -40 ° C کان 125 ° C makes sure integrity in harsh settings. Materials made use of in building and construction influence efficiency. Aluminum housings use lightweight resilience. Shielded substrates lower electric leak. Security accreditations are non-negotiable. Compliance with UL, CE, or RoHS requirements guarantees top quality. Placing alternatives differ. Screw terminals simplify setup. PCB-mounted versions match compact layouts. Reverse voltage defense prevents damage from inaccurate circuitry. Surge tolerance is essential. The rectifier must stand up to short-term voltage spikes without breakdown. Efficiency scores over 95% decrease power loss. Reduced ahead voltage decline minimizes heat generation. Packaging has to withstand dampness and dust. IP-rated units are perfect for industrial settings. Checking under load conditions confirms real-world performance. Customization choices consist of flexible output voltages. Compatibility with single-phase or three-phase systems broadens application extent. Maintenance demands are reduced. Regular examination of links guarantees long-term functionality. Appropriate sizing avoids straining. Speak with maker datasheets for precise requirements. Bridge rectifiers for brake electric motors focus on reliability. They make sure continuous electric motor stopping. Right option equilibriums price and efficiency. Always validate compatibility with the motor’s electrical criteria.

(bridge rectifier for brake motor)

Applications of bridge rectifier for brake motor

Bridge rectifiers play a crucial role in brake electric motor systems. اهي متبادل موجوده کي تبديل ڪن ٿا (اي سي) to guide current (ڊي سي). This conversion is necessary for brake motors to work correctly. Brake motors depend on electro-magnetic brakes to quit quickly. These brakes need a stable DC power supply. Bridge rectifiers give this by changing the air conditioning input from the power source right into DC outcome. The procedure makes sure the brake involves efficiently and dependably.

Industrial machinery commonly makes use of brake motors with bridge rectifiers. Conveyor belts are a common instance. They must stop promptly to prevent accidents or product damage. The rectifier assures the brake obtains constant DC power. This enables the motor to halt the belt immediately. Elevator systems additionally rely on these parts. Sudden stops are critical for traveler safety. The rectifier ensures the brake activates instantly when required.

Bridge rectifiers improve efficiency in brake electric motor applications. They minimize power loss throughout AC-to-DC conversion. This maintains the system running colder. Overheating dangers decrease. The design of bridge rectifiers sustains compact electric motor setups. Space-saving is necessary in devices like CNC devices or robotics. Smaller sized components indicate simpler assimilation right into limited rooms.

Resilience matters in rough atmospheres. Bridge rectifiers manage high voltage and existing degrees. They hold up against vibrations and temperature level adjustments usual in factories. This integrity reduces maintenance requirements. Downtime decreases. Assembly line stay operational much longer.

Brake electric motors in automobile manufacturing use bridge rectifiers. Setting up robots call for exact stopping during jobs. The rectifier supplies steady DC power for consistent brake performance. Mistakes in positioning parts are avoided. Product quality remains high.

Bridge rectifiers also enhance security. Without trusted DC power, brakes could fail. Devices could malfunction. The rectifier serves as a safeguard. It ensures the brake engages whenever. Workers operate equipment with confidence.

Personalization options exist for various brake electric motor setups. Rectifiers are available in numerous sizes and power ratings. They match details voltage needs. Compatibility with different motor types is ensured. Upgrading existing systems ends up being straightforward.

ڪمپني پروفائل

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) پاور اليڪٽرانڪس ٽيڪنالاجي ۽ پاور پروڊڪٽس ۾ معروف ادارن مان هڪ آهي, جيڪو مڪمل طور تي سولر انورٽرز ٺاهڻ ۾ شامل آهي, ٽرانسفارمر, وولٹیج ريگيوليٽر, تقسيم ڪابينا, thyristors, ماڊلز, ڊيوڊس, هيٽر, ۽ ٻيا اليڪٽرانڪ ڊوائيسز يا سيمي ڪنڊڪٽرز. اسان صارفين کي اعلي معيار سان مهيا ڪرڻ لاء پرعزم ڪيو ويندو, موثر پروڊڪٽس ۽ غور جي خدمت.

اهو ڪريڊٽ ڪارڊ ذريعي ادائيگي قبول ڪري ٿو, ٽي/ٽي, ويسٽ يونين, ۽ Paypal. PDDN FedEx ذريعي اوورسيز گراهڪن کي سامان موڪليندو, ڊي ايڇ ايل, سمنڊ ذريعي, يا هوا ذريعي. If you want high-quality bridge rectifier for brake motor, مهرباني ڪري اسان کي انڪوائري موڪليو; اسان توهان جي مدد ڪرڻ لاء هتي هونداسين.

ادائگي جا طريقا

ايل/سي, ٽي/ٽي, ويسٽرن يونين, پي پال, ڪريڊٽ ڪارڊ وغيره.

ترسيل

سمنڊ ذريعي, هوا ذريعي, اظهار ذريعي, جيئن گراهڪن جي درخواست.

اسٽوريج جون حالتون

1) ڪمري جي حرارت تي خشڪ ماحول ۾ ذخيرو ڪريو.

2) نم ۽ اعلي درجه حرارت کان بچاء.

3) اندروني پيڪنگ بيگ کولڻ کان پوء فوري طور تي استعمال ڪريو.

5 FAQs of bridge rectifier for brake motor

A bridge rectifier changes AC to DC power. Brake motors need steady DC power to work right. The rectifier makes sure the motor’s brake gets stable DC voltage. This stops the brake from slipping or failing. Without it, the motor might not stop safely.

People ask why bridge rectifiers are used in brake motors. Brake systems need DC power to hold the motor still when it’s off. AC power alone can’t do this. The rectifier fixes the AC power into DC. This keeps the brake engaged until the motor starts again.

People wonder how to pick the right bridge rectifier. Check the motor’s voltage and current needs. Match the rectifier’s voltage rating to the motor’s AC supply. Make sure the current rating is higher than the motor’s max load. This stops overheating. A higher-rated rectifier lasts longer.

People ask how to install a bridge rectifier. Connect the AC input terminals to the motor’s power supply. Link the DC output terminals to the brake coil. Double-check the wiring matches the diagram. Wrong connections damage the rectifier or brake. Test the system slowly after installing.

People worry about common problems. No output voltage means the rectifier might be broken. Check for burnt parts or loose wires. Low voltage could mean a failing diode. Overheating happens if the rectifier is too small for the load. Always use a rectifier with enough capacity. Keep it cool and clean.

(bridge rectifier for brake motor)

هڪ اقتباس جي درخواست ڪريو

لاڳاپيل مصنوعات

Haney rectifier module telecom power rectifier

RECTIFIER KD-190

Diode Bridge Rectifier KBPC5010 Bridge Rectifier

S1JHE3 (CHY BOM Service)Rectifiers DO-214AC-2 S1JHE3_A/H

12V-4000A plating rectifier with reversing