Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

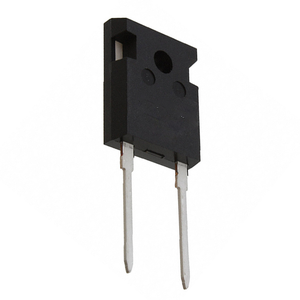

Overview of Thyristor Modules

Thyristor modules are key components in power electronics technology. They consist of one or more thyristors encapsulated in a compact housing. Thyristors are four-layer, three-terminal semiconductor devices that are primarily used in applications that control and regulate high-power AC or DC current. They can quickly switch from a high-impedance state to a low-impedance conduction state based on a trigger signal, thereby achieving precise control of current.

Features and Benefits of Thyristor Modules

High power handling capability: Thyristor modules can withstand extremely high voltages and currents, making them suitable for industrial-grade power conversion and control systems.

Fast response time: Very short switching times and low losses ensure high-efficiency operation.

Reliability and durability: Rugged design, stable operation in harsh environments, and long life.

Easy integration: Modular design simplifies installation and reduces maintenance requirements.

Overload protection: Built-in protection mechanisms such as over-temperature and over-current protection enhance system safety.

Versatile applications: Widely used in a variety of applications requiring precise current control.

(Thyristor thyristor module quality good various models)

Specification of Thyristor thyristor module quality good various models

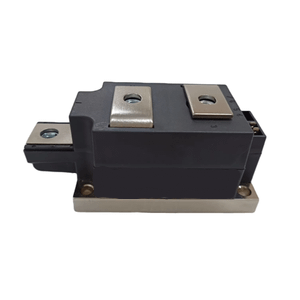

Thyristor modules are digital elements used to control high-power circuits in industrial tools. These components deal with switching and policy tasks in systems like electric motor drives, power supplies, home heating controls. The top quality of a thyristor component depends upon its layout, products, manufacturing requirements. Excellent modules guarantee secure performance, lengthy service life, marginal failing rates.

Trick specifications define the capacities of thyristor components. Voltage scores range from a couple of hundred volts to several kilovolts. Present scores range components, generally from tens to thousands of amperes. Thermal efficiency matters. Top quality modules manage heat effectively making use of advanced heatsinks or incorporated air conditioning systems. Leakage existing levels remain low also under high temperatures. This avoids energy loss.

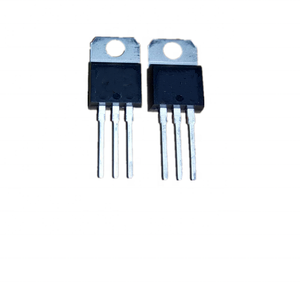

Different versions fit different applications. Criterion components take care of standard changing tasks. Crooked components take care of DC voltage systems. Bidirectional kinds work with air conditioning circuits. Fast-switching models sustain high-frequency procedures. Reverse-blocking abilities vary between models. Customers pick based upon voltage polarity requirements.

Product quality effects durability. Reputable thyristor components make use of high-grade silicon for the semiconductor layer. Copper or aluminum substrates boost thermal conductivity. Ceramic insulators stop electrical leakage. Durable housings protect versus dirt, dampness, resonance. Production precision makes sure regular get in touch with between layers. This lowers resistance, stays clear of hotspots.

Evaluating procedures confirm performance. Respectable vendors subject components to stress tests. These include thermal cycling, high-voltage endurance tests, tons surge simulations. Accreditations like ISO 9001 or UL criteria show conformity with safety standards. Deducible production data permits high quality audits.

Thyristor modules serve markets like steel production, railway systems, renewable energy plants. Custom arrangements adjust to specific voltage or current needs. Modular designs streamline substitute. Compatibility with control circuits differs. Individuals inspect entrance trigger parameters to match their systems.

Defense attributes avoid damage. Overvoltage snubbers absorb voltage spikes. Fuse compatibility includes safety. Some designs integrate temperature level sensors. These trigger closures during overheating. Upkeep needs remain low for well-made modules.

Performance uniformity divides excellent modules from inferior ones. Stable switching attributes guarantee smooth procedure. Marginal delay times improve action precision. Reduced harmonic distortion safeguards linked tools. Providers give datasheets with comprehensive specifications. Individuals contrast metrics like holding present, essential price of voltage surge.

Diverse versions deal with special industrial demands. Quality-focused manufacturing ensures dependability under rough problems. Appropriate option takes full advantage of efficiency, lowers downtime.

(Thyristor thyristor module quality good various models)

Applications of Thyristor thyristor module quality good various models

Thyristor components are vital elements in modern electronics. They take care of high power levels effectively. These gadgets control electrical power in many industrial configurations. Their ability to change quickly makes them helpful in power law.

Industries utilize thyristor components extensively. Power systems rely on them for voltage change. Motor control systems rely on their precise changing. Renewable resource setups make use of these modules to manage grid connections. They maintain power circulation in wind turbines and photovoltaic panels. Industrial heating units employ thyristors for temperature control.

Quality issues for thyristor components. Great modules last longer under anxiety. They deal with high voltages without failure. Robust building stops damages from warm or surges. Trusted thyristors minimize downtime in vital applications. Manufacturers examination components rigorously. Electrical performance checks make sure stability. Thermal examinations confirm heat resistance. Safety and security criteria assure user security.

Numerous versions match different requirements. Low-power modules work in small devices. High-power variations manage hefty industrial tons. Some components focus on fast changing speeds. Others focus on voltage handling. Compact layouts fit space-limited arrangements. Modular systems allow very easy expansion.

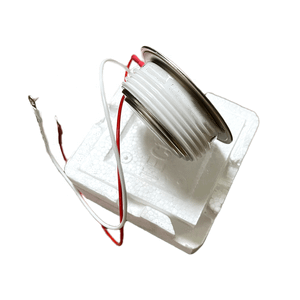

Cooling down approaches differ. Air-cooled modules suit basic environments. Liquid-cooled alternatives take care of severe warmth. Passive cooling works for low-duty cycles. Active air conditioning supports constant operation. Custom-made configurations meet customized demands.

Thyristor components adjust to multiple industries. Manufacturing plants utilize them for equipment control. Transportation systems integrate them into electric vehicle billing. Power industries apply them in transmission networks. Their adaptability makes them essential.

Longevity makes certain cost-effectiveness. Top notch materials withstand wear. Correct insulation stops electrical leaks. Regular efficiency lowers upkeep needs. Customers minimize substitute expenses.

Choosing the ideal design needs evaluation. Voltage ratings have to match application needs. Present ability should surpass anticipated lots. Ecological problems affect cooling down selections. Compatibility with existing systems is important. Vendors give technical assistance for choice.

Thyristor components develop with technology. Advances enhance effectiveness and compactness. Advancements focus on smarter control features. Combination with digital systems boosts functionality. Future growths will expand their applications additional.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor thyristor module quality good various models, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor thyristor module quality good various models

What factors show a thyristor module has good quality?

High-quality thyristor modules use durable materials. Proper heat management prevents overheating. Manufacturing must follow strict standards. Check voltage and current ratings match requirements. Certifications like ISO or UL indicate tested reliability.

Do different thyristor models vary in quality?

Models differ based on design and application. Some handle higher power loads. Others focus on precision control. Quality depends on specs matching the use case. Industrial models often have stronger heat sinks. Verify the model’s specs align with your needs.

How to test a thyristor module’s reliability?

Run thermal stress tests to check heat tolerance. Measure voltage leakage under maximum load. Test switching speed consistency. Inspect for physical defects like cracks or loose connections. Long-term performance data from manufacturers helps assess durability.

What common issues affect thyristor module quality?

Poor soldering causes weak electrical connections. Inadequate cooling leads to early failure. Low-grade materials reduce lifespan. Voltage spikes damage unprotected modules. Ensure proper installation and use surge protection. Regular maintenance avoids dust buildup.

How to pick the right thyristor model for my project?

Match voltage and current ratings to your system’s demands. Check if the module works in your temperature range. High-frequency applications need fast switching models. Compare warranties and manufacturer support. Read user reviews for real-world feedback.

(Thyristor thyristor module quality good various models)

REQUEST A QUOTE

RELATED PRODUCTS

thyristor Hot offer diode module TMTC 570-14 on auxiliary inverters, motor drives and servo drives and and PFC

Thyristor Diode Module 200A Single Phase Diode Bridge DSEI2X101-12A

electronics component IGBT MODULE Diode Thyristor SCR transistors mosfet IC chips FS100R12KT4G

STOCK electronics component IGBT MODULE Diode Thyristor SCR transistors mosfet IC chips 70HF120

New and original IGBT DIODE Power module 6MBP30RH060 DIODE Thyristor SCR