Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Introduction to Thyristor Diode Modules

Thyristor diode modules, often simply referred to as thyristors, are a type of semiconductor device used primarily for controlling and switching electrical power in various applications. They act as controlled switches, allowing current to flow when triggered by a small gate signal. Once turned on, they remain conducting until the current through them falls below a certain threshold or the direction of the current is reversed.

A thyristor module typically consists of multiple thyristors packaged together to handle higher currents or voltages than a single component could manage. These modules can be found in a variety of configurations, including SCR (Silicon Controlled Rectifier), TRIAC, and GTO (Gate Turn-Off) thyristors, each designed for specific types of power control tasks.

Features and Advantages of Thyristor Diode Modules

-

High Power Handling Capacity:

Thyristor modules are capable of handling high levels of power, making them suitable for industrial applications that require robust and reliable power management solutions. -

Efficient Power Control:

Thyristors offer precise control over the power delivered to a load. By controlling the timing of the gate pulse, it’s possible to adjust the amount of power being transferred, which is particularly useful in AC power control applications such as dimming lights or speed control of motors. -

Low Conduction Losses:

When fully on, thyristors have low forward voltage drops, resulting in minimal power losses during conduction. This efficiency contributes to lower operating temperatures and improved energy efficiency. -

Rugged Construction:

Designed for harsh environments, thyristor modules feature durable packaging that can withstand mechanical stress, temperature fluctuations, and other environmental factors typical in industrial settings. -

Compact Design:

Despite their ability to handle significant power, modern thyristor modules are compact, enabling space-saving designs in equipment where size and weight are critical considerations. -

Cost-Effective Solution:

Thyristor modules provide an economical way to implement powerful switching and control functions compared to alternative technologies that might not be as efficient or may cost more per unit of power handled. -

Simple Triggering Mechanism:

Thyristors require only a small gate current to turn on, which simplifies the design of control circuits. The triggering mechanism can be easily integrated into existing systems with minimal additional components. -

Wide Range of Applications:

From motor control and power supplies to welding machines and traction systems, thyristor modules find application across a broad spectrum of industries due to their versatile characteristics. -

Overcurrent Protection:

Many thyristor modules come equipped with built-in protection features against overcurrent conditions, safeguarding both the device itself and connected loads from potential damage. -

Fast Switching Speeds:

Advanced thyristor modules can switch states rapidly, which is beneficial in applications requiring quick response times or frequent switching cycles without compromising performance.

(Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04)

Specification of Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04

The rectifier diode modules SKN4000/06, SKN4000/04, SKN4000/02, and SKN6000/04 are made for high-power applications. These modules supply trustworthy efficiency in converting rotating present (AIR CONDITIONING) to route present (DC). They are constructed to deal with requiring industrial settings.

The SKN4000 collection consists of models with voltage rankings of 2000V, 4000V, and 6000V. The SKN4000/06 operates at 6000V, the SKN4000/04 at 4000V, and the SKN4000/02 at 2000V. All SKN4000 versions support an optimal standard onward current of 4000A. The SKN6000/04 offers a greater existing capacity, ranked for 6000A at 4000V. This makes it ideal for systems requiring raised power handling.

Each component uses high-grade silicon diodes. These diodes guarantee low ahead voltage drop. They decrease power loss during operation. The components include a durable building. They include copper base plates for reliable warmth dissipation. This layout prevents overheating under heavy tons.

The rectifier modules work with common mounting systems. They include screw terminals for safe and secure electrical links. Maintenance is simplified because of their modular layout. Fallen short components can be replaced without disassembling the whole system.

Running temperature ranges from -40 ° C to +150 ° C. This enables usage in extreme conditions. The components are immune to moisture, dust, and vibrations. They meet worldwide security requirements. Qualifications consist of IEC and UL acknowledgment.

Applications include industrial electric motor drives, power materials, welding equipment, and grip systems. They are likewise utilized in renewable resource systems like wind generators and solar inverters. The high surge present capacity makes certain dependability during unexpected load modifications.

Checking includes extensive thermal biking and voltage endurance checks. Each system goes through quality assurance before shipment. This guarantees constant efficiency.

The components are packaged independently in anti-static products. Storage space standards suggest keeping them in dry, temperature-controlled atmospheres. Technical assistance is offered for setup and troubleshooting.

These rectifier diode modules focus on longevity and effectiveness. They minimize downtime in critical operations. Their style concentrates on long-lasting stability under continuous use.

(Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04)

Applications of Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04

The SKN4000/06, SKN4000/04, SKN4000/02, and SKN6000/04 rectifier diode modules are created for transforming rotating current to direct present in high-power systems. These modules offer vital roles across industries due to their reliability and efficiency. Industrial machinery typically uses them for welding equipment, electric motor drives, and battery billing systems. Their ability to deal with heavy tons makes them appropriate for extreme environments like manufacturing plants.

Power supply devices in telecommunications infrastructure and information centers rely on these modules. Steady DC outcome guarantees undisturbed operation of web servers and communication tools. The SKN6000/04 model sustains higher voltage needs, ideal for massive power distribution. Renewable energy systems like solar inverters and wind generators likewise use these diodes. Efficient power conversion reduces power loss during transmission from renewable resources to grids.

Automotive applications consist of electrical automobile billing stations and onboard power systems. Rapid switching abilities reduce energy waste, improving charging effectiveness. Mass transit systems such as trains and trams take advantage of these components. They manage power for propulsion and supporting systems, guaranteeing smooth operation.

The SKN4000 series masters compact layouts, suitable space-limited setups without giving up performance. Thermal monitoring features avoid overheating during long term use. This prolongs the lifespan of both the diodes and connected tools. Designers pick these components for their longevity under fluctuating voltages and temperatures.

Industrial automation devices like CNC makers and robot arms depend upon steady DC power. The SKN4000/02 design is commonly integrated into control circuits for precision operations. Consumer electronic devices making lines use these diodes to evaluate and calibrate high-power tools. Constant performance minimizes defects in final result.

These rectifier diode components are functional solutions for modern power needs. Their adaptability across industries highlights their significance in keeping effective power use.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04

The rectifier diode modules SKN4000/06, SKN4000/04, SKN4000/02, and SKN6000/04 are designed for high-power industrial applications. Below are answers to common questions about these modules.

What are these rectifier diode modules used for?

These modules convert alternating current (AC) to direct current (DC). They are used in welding equipment, battery chargers, motor drives, and power supplies. They handle high voltage and current levels, making them suitable for heavy-duty industrial systems.

How do the SKN4000 models differ from the SKN6000/04?

The SKN4000 series includes models with voltage ratings of 200V (SKN4000/02), 400V (SKN4000/04), and 600V (SKN4000/06). The SKN6000/04 has a higher current rating of 6000A compared to the SKN4000 series’ 4000A. Choose based on the voltage and current requirements of your application.

What is the maximum operating temperature?

All modules operate safely up to 150°C. Proper cooling is necessary to maintain performance. Use heat sinks or forced air cooling in high-load conditions. Exceeding the temperature limit may reduce lifespan or cause failure.

How are these modules installed?

Mount the module on a clean, flat surface with good thermal conductivity. Secure terminals tightly to avoid loose connections. Follow the torque specifications in the datasheet. Ensure correct polarity when wiring. Test the system at low power before full operation.

Are there safety precautions for using these modules?

Yes. Wear protective gear during installation. Avoid touching live terminals. Check for insulation damage before use. Do not expose the modules to moisture or corrosive environments. Follow local electrical safety standards. Regular maintenance helps prevent unexpected failures.

(Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04)

REQUEST A QUOTE

RELATED PRODUCTS

1N4007 Original DIODE STD DO-41 1000V 1A Single Diodes Electronic components integrated circuit Bom SMT PCBA service

low power consumption high light efficiency light emitting diode

In stock original new Thyristor / Diode Module, Series Connected, 106 A, 1.6 kV SKKH 106 16E

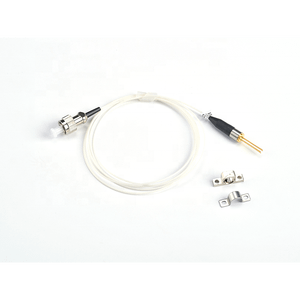

Diode laser stack LT HPL UPP KR STE CLE BML HYN American Coherent Bars laser transmitter emitter laser module 808 1064 755 810nm

Portable diode module laser stack 24-bar micro channel 808nm diode laser bar stack module for diode laser