Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

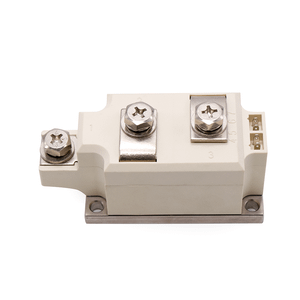

Introduction to Thyristor Diode Modules

Thyristor diode modules, often simply referred to as thyristors, are a type of semiconductor device used primarily for controlling and switching electrical power in various applications. They act as controlled switches, allowing current to flow when triggered by a small gate signal. Once turned on, they remain conducting until the current through them falls below a certain threshold or the direction of the current is reversed.

A thyristor module typically consists of multiple thyristors packaged together to handle higher currents or voltages than a single component could manage. These modules can be found in a variety of configurations, including SCR (Silicon Controlled Rectifier), TRIAC, and GTO (Gate Turn-Off) thyristors, each designed for specific types of power control tasks.

Features and Advantages of Thyristor Diode Modules

-

High Power Handling Capacity:

Thyristor modules are capable of handling high levels of power, making them suitable for industrial applications that require robust and reliable power management solutions. -

Efficient Power Control:

Thyristors offer precise control over the power delivered to a load. By controlling the timing of the gate pulse, it’s possible to adjust the amount of power being transferred, which is particularly useful in AC power control applications such as dimming lights or speed control of motors. -

Low Conduction Losses:

When fully on, thyristors have low forward voltage drops, resulting in minimal power losses during conduction. This efficiency contributes to lower operating temperatures and improved energy efficiency. -

Rugged Construction:

Designed for harsh environments, thyristor modules feature durable packaging that can withstand mechanical stress, temperature fluctuations, and other environmental factors typical in industrial settings. -

Compact Design:

Despite their ability to handle significant power, modern thyristor modules are compact, enabling space-saving designs in equipment where size and weight are critical considerations. -

Cost-Effective Solution:

Thyristor modules provide an economical way to implement powerful switching and control functions compared to alternative technologies that might not be as efficient or may cost more per unit of power handled. -

Simple Triggering Mechanism:

Thyristors require only a small gate current to turn on, which simplifies the design of control circuits. The triggering mechanism can be easily integrated into existing systems with minimal additional components. -

Wide Range of Applications:

From motor control and power supplies to welding machines and traction systems, thyristor modules find application across a broad spectrum of industries due to their versatile characteristics. -

Overcurrent Protection:

Many thyristor modules come equipped with built-in protection features against overcurrent conditions, safeguarding both the device itself and connected loads from potential damage. -

Fast Switching Speeds:

Advanced thyristor modules can switch states rapidly, which is beneficial in applications requiring quick response times or frequent switching cycles without compromising performance.

(High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction)

Specification of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

This premium utilized blue dot laser diode component is designed for accuracy inscription and cutting in construction applications. It delivers dependable performance while preserving cost efficiency. The component runs at a wavelength of 450nm, producing a focused blue laser beam suitable for thorough work on products like steel, wood, and plastic. Its outcome power varies from 2W to 5W, flexible to match various task demands.

The laser diode features a durable real estate constructed from anodized light weight aluminum. This ensures resistance to damage in demanding building atmospheres. A built-in air conditioning system stops overheating during expanded use. Stable temperature level control prolongs the component’s lifespan. The light beam divergence is maintained listed below 1.5 mrad, ensuring sharp focus for accurate cuts and engravings.

This component sustains multiple control user interfaces, consisting of analog and PWM signals. Compatibility with typical CNC systems simplifies combination into existing workflows. Security devices include overload protection and emergency situation quit functions. These lower dangers during procedure.

Each device undergoes strenuous testing prior to resale. Secret parts like the laser diode, chauffeur board, and optics are inspected for flaws. Performance metrics are validated to match initial specs. Minor cosmetic blemishes might exist but do not influence capability.

Heaven dot laser light beam gives high exposure, making it much easier to line up with target surface areas. This minimizes configuration time and boosts operational effectiveness. Applications include etching identification numbers on building materials, cutting slim metal sheets, and noting safety and security guidelines on devices. Power effectiveness reduces power consumption compared to typical carbon dioxide lasers.

Customization alternatives are readily available for focal size and installing brackets. This makes certain adaptability to specific machinery or project requirements. Replacement components come for lasting maintenance. The component’s small design conserves space in workshop arrangements.

Operational sound degrees remain listed below 50dB, reducing workplace disturbance. A 1 year warranty covers manufacturing issues. Technical assistance is offered setup and troubleshooting. Mass acquisition discounts obtain larger building and construction firms.

(High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction)

Applications of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

High-quality made use of blue dot laser diode modules offer sensible services for accuracy engraving and reducing in construction. These components deliver concentrated laser beam of lights suitable for thorough work on numerous products. Construction specialists rely upon them for jobs calling for precision and consistency.

Heaven dot laser diode module masters etching surfaces like wood, metal, and concrete. It develops sharp markings for labels, security signs, or attractive aspects on building components. The high-intensity beam of light makes sure tidy outcomes without harmful surrounding locations. This minimizes product waste and improves job timelines.

Cutting applications gain from the component’s capacity to manage slim to medium-thick materials. It cuts through floor tiles, acrylic sheets, and steel panels with very little errors. The precision lessens adjustments during setup. Workers accomplish tighter suitable for pipes, electric systems, or architectural components. This results in better total develop top quality.

Standard cutting devices usually create rough sides or need numerous passes. The laser component completes tasks in one step. It decreases labor prices and tools wear. Construction teams conserve time on post-processing.

Longevity makes these modules appropriate for demanding job websites. They withstand resonances, dust, and temperature adjustments. Upkeep demands are low. Utilized components go through comprehensive screening to guarantee performance matches new devices. Budget-conscious tasks obtain reputable modern technology without high costs.

Energy performance is one more advantage. The diode style utilizes much less power than traditional lasers. Running costs stay manageable over long periods. Projects preserve efficiency without excessive energy bills.

Safety and security attributes shield customers and materials. The module includes safety real estates and automated shut-off mechanisms. Exposure to route light or overheating threats go down significantly. Workers concentrate on tasks without constant disturbances.

Convenience allows the component to adjust to different job demands. Adjustable power setups and beam of light sizes take care of varied products and densities. Service providers change between inscription and cutting tasks swiftly. Hold-ups from devices changes decrease.

Heaven dot laser diode module sustains modern building and construction needs. It combines precision, toughness, and cost-effectiveness. Experts attain premium outcomes while meeting tight target dates and budgets.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

What makes this laser diode module good for construction work? The module is built to last. It uses strong materials that handle heavy use. Dust, moisture, and high heat won’t break it. This keeps performance steady during long jobs. Construction sites need tools that survive rough conditions. This laser meets that need.

Can it work with existing machines? Yes. The design fits standard engraving and cutting systems. Mounts and connectors match common setups. Check your machine’s specs before buying. Most brands like XYZ or ABC Tools support this module. Installation takes minutes. No extra parts are needed.

Is it safe for workers? Safety comes first. The module has automatic shutdown if it overheats. Protective housing blocks accidental contact with the laser beam. It meets international safety standards like CE and RoHS. Always wear safety goggles when operating it. Training workers on proper use is still important.

How often does it need maintenance? Clean the lens every 50 hours of use. Wipe dust off the vents weekly. Check electrical connections monthly. Replace worn parts like cooling fans yearly. Maintenance is simple. No special tools are required. Store it in a dry place when not in use. This prevents rust or damage.

Does it work on different materials? The laser cuts or engraves metal, wood, plastic, and stone. Adjust the power and focus for each material. Higher power handles thicker metals. Lower settings work for delicate engravings on wood. Test settings on scrap material first. This ensures clean results. Consistency matters for professional construction projects.

(High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction)

REQUEST A QUOTE

RELATED PRODUCTS

Set Beam Cross Laser Locator for Embroidery Machine Positioner Measurement Printer Diode Laser Module 20*90 660nm 100mw Red

MDD44-16N1B New Original DIODE MODULE GP 1.6KV 64A TO240AA IGBT Module MDD 44-16 N1B MDD44 16N1B MDD44-16N1B

HD-8A36 HD-8A50 HD-8280 HD-K280 HD-8AA6 808nm 810nm 790nm transmitter diode laser stack module for hair removal

Rectifier Diode Module SKN4000/06 SKN4000/04 SKN4000/02 SKN6000/04

HD 808nm 810nm 790nm 4bars 5bars 6bars 8bars 16bars 32bars 10bars diode laser stack module for hair removal