Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

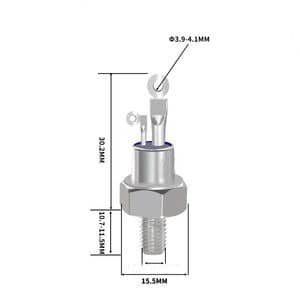

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

(VOITA hot rectifier module 48V 50A rectifier system for electroplating)

Specification of VOITA hot rectifier module 48V 50A rectifier system for electroplating

The VOITA 48V 50A Hot Rectifier Module is designed for electroplating applications. It delivers stable DC power to ensure consistent plating quality. The system operates with high efficiency. It meets industrial demands for reliability. The input voltage range is 85-265V AC. This allows compatibility with most power grids globally. The output provides 48V DC at 50A. The total power capacity reaches 2400W. This suits medium to large-scale electroplating setups.

The rectifier uses advanced switching technology. This reduces energy loss. Conversion efficiency exceeds 92%. Operating costs stay low. The module includes overload protection. Short-circuit safeguards prevent damage. Automatic voltage stabilization maintains output accuracy. Fluctuations in input power do not affect performance.

Heat management is critical. The system integrates a high-speed cooling fan. An aluminum heatsink dissipates heat effectively. Internal temperature sensors trigger adjustments. This avoids overheating during prolonged use. The enclosure is made of fire-resistant materials. Safety certifications include CE and RoHS.

Control features are user-friendly. A digital display shows real-time voltage and current. Adjustments are made via buttons or rotary knobs. Remote monitoring is optional. Compatibility with PLC systems enables automation. Installation is straightforward. Mounting brackets secure the unit in place. Wiring terminals are clearly labeled.

The rectifier supports precise current density control. This is vital for uniform metal deposition. Applications include nickel, copper, zinc, and chromium plating. The system works in harsh environments. Dust and moisture resistance extends lifespan. Maintenance requirements are minimal. Regular cleaning of vents ensures optimal airflow.

Industrial users prioritize durability. Components are tested under extreme conditions. The design minimizes vibration impact. Electrical noise is suppressed. Nearby equipment operates without interference. Custom configurations are available. Voltage or current ratings can be adjusted. Technical support is provided for integration.

This rectifier suits factories, workshops, and labs. It balances power output with energy savings. Operational stability reduces downtime. Electroplating results meet high standards.

(VOITA hot rectifier module 48V 50A rectifier system for electroplating)

Applications of VOITA hot rectifier module 48V 50A rectifier system for electroplating

The VOITA 48V 50A hot rectifier module is designed for electroplating applications. This system provides stable DC power to ensure precise control over plating processes. It converts AC to DC efficiently, maintaining consistent voltage and current output. These features make it ideal for industrial electroplating tasks requiring accuracy and reliability.

Electroplating uses electrical currents to coat metal surfaces with thin layers of other metals. The VOITA rectifier supports this by delivering adjustable voltage and current settings. Users can fine-tune parameters to match specific plating requirements. This flexibility suits applications in automotive parts, electronics, jewelry, and machinery manufacturing.

The system handles high workloads without performance drops. Its 48V 50A capacity manages thick coatings or large batches. Advanced cooling mechanisms prevent overheating during extended operations. Built-in protection against surges, short circuits, and overloads enhances durability. This reduces downtime and maintenance costs.

Energy efficiency is a key advantage. The rectifier minimizes power waste, lowering electricity expenses. Its compact design saves space in crowded workshops. Simple installation allows quick integration into existing setups. Operators can monitor real-time data via the interface, making adjustments as needed.

The VOITA rectifier works with various plating solutions. It supports nickel, copper, zinc, and chromium processes. Stable output prevents uneven plating or defects. Consistent results improve product quality and reduce material waste.

Safety features protect both equipment and users. Automatic shutdown activates during faults. Insulated components reduce electric shock risks. The system meets international safety standards for industrial environments.

User-friendly controls simplify operation. Even inexperienced workers can manage settings with minimal training. Preset modes for common tasks speed up workflow. Compatibility with automation systems enables seamless integration into advanced production lines.

Durability ensures long-term use in harsh conditions. Corrosion-resistant materials withstand exposure to chemicals and humidity. Regular maintenance is straightforward, requiring basic checks and cleaning.

The VOITA 48V 50A rectifier meets the demands of modern electroplating. Its combination of precision, reliability, and safety makes it a practical choice for industries aiming to optimize plating efficiency.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality VOITA hot rectifier module 48V 50A rectifier system for electroplating, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of VOITA hot rectifier module 48V 50A rectifier system for electroplating

What makes the VOITA 48V 50A rectifier system suitable for electroplating?

The VOITA rectifier delivers precise voltage and current control. Electroplating needs steady power to ensure even coating on materials. This system adjusts output smoothly. It handles high loads without fluctuations.

How does the system protect against electrical faults?

Built-in safeguards prevent overloads and short circuits. The module monitors temperature constantly. If overheating happens, it shuts down automatically. Surge protection shields against voltage spikes. Alerts notify users of issues quickly.

Is maintenance complicated for this rectifier?

Routine upkeep is simple. Dust filters need cleaning every few weeks. Terminals and connections should be checked for corrosion monthly. Software updates are rare but easy to install via USB. No specialized tools are required.

Can this rectifier reduce energy costs?

Yes. The system converts AC to DC power efficiently. Less energy gets wasted as heat. Lower operating temperatures mean cooling needs drop. Over time, this cuts electricity bills. Stable output also reduces material waste in plating.

What if the rectifier stops working suddenly?

First, check the power supply and circuit breakers. Ensure cooling fans are running. Reset the system if error codes appear. If problems continue, contact support. Faulty parts can be replaced quickly without returning the whole unit.

(VOITA hot rectifier module 48V 50A rectifier system for electroplating)

REQUEST A QUOTE

RELATED PRODUCTS

T30 Rectifier Diode Bridge Rectifier Diode Set Generator Rectifier Module

Industrial Controls High Quality Bridge Rectifier Scr Thyristor PK25F80 for Sanre

Good thermal performance Temperature shock resistance ESD sensitivity level 3A Rectifier Diode A2CZ232

FR101-FR107 Plastic Fast Recovery Rectifiers

Good Quality Standard Recovery Diode Rectifier DS1112SG60 with good quality