Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

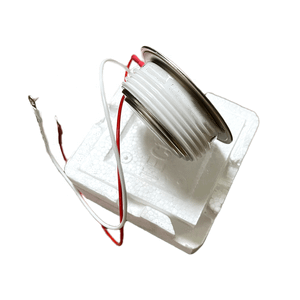

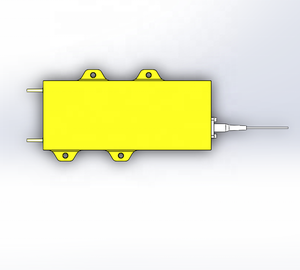

(Rectifier Plating power supply High-frequency rectifiers)

Specification of Rectifier Plating power supply High-frequency rectifiers

High-frequency rectifier layering power supplies transform a/c power right into steady DC power for electroplating work. They deal with tough commercial setups well. Input voltage options include 380V three-phase or 220V single-phase. Outcome changes efficiently from absolutely no to 3000 amps present and no to 18 volts. This array matches various plating tasks like chrome, nickel, or zinc.

These units make use of IGBT high-frequency changing tech. This makes them compact and energy-smart. Efficiency hits over 90%. Less power obtains wasted as heat. They run cooler than old-style silicon rectifiers. Cooling approaches vary. Some utilize solid fans for air circulation. Others require water air conditioning for hefty loads.

Defense features are built-in. Over-voltage shutdown stops damage if spikes take place. Over-current cut-off guards against short circuits. Over-temperature sensing units avoid getting too hot. Automatic healing kicks in after mistakes clear.

Control is user-friendly. Digital screens reveal voltage and amperage numbers. Buttons or knobs set worths exactly. Remote procedure functions via computer system interfaces. Ripple rates stay low. This provides smooth layering layers without bumps or burns.

Applications cover electroplating, anodizing, and metal polishing. They fit auto parts producing, jewelry finish, and circuit card manufacturing. Tough steel cases secure inner parts from dust and chemicals. Upkeep stays straightforward. Just check fans and links regularly.

Custom setups are possible. Required greater amperage? Unique designs surpass 5000 amps. Voltage can reach 24 volts for certain procedures. These power supplies boost performance. They reduced energy costs. They ensure even metal deposition every time.

(Rectifier Plating power supply High-frequency rectifiers)

Applications of Rectifier Plating power supply High-frequency rectifiers

High-frequency rectifier layering power materials transform AC power right into DC power. This DC power drives electroplating procedures. They work in a different way than older transformer versions. These systems switch over power very quickly. This high-speed switching creates stable DC result. Exact control matters for high quality plating results.

These power materials excel in ornamental plating applications. Precious jewelry manufacturers use them for gold, silver, and rhodium plating. They provide brilliant, also surfaces. Automotive trim plating likewise advantages. Consistent chrome plating on car components needs this stability. The power adjusts promptly to keep the finish perfect. This avoids boring areas or roughness.

Practical plating counts heavily on these rectifiers too. Zinc or nickel plating safeguards steel parts from rust. Factories apply these layers on nuts, bolts, and automobile components. Uniform density is critical for long life. High-frequency devices supply this reliably. They manage the high currents required for thick down payments. They likewise handle the chemistry well.

Electronic devices manufacturing uses these power supplies extensively. Circuit boards require specific copper plating for their small pathways. Connector pins require specific gold or tin plating. High-frequency rectifiers offer the fine control this demands. They protect against burning delicate components. They maintain continuous current thickness over intricate shapes.

Industrial hard chrome plating is one more major location. Hydraulic rods and industrial rollers require tough chrome surface areas. This plating requires high power and secure voltage. High-frequency rectifiers provide this efficiently. They run cooler than old systems. This saves power and decreases costs. Their integrity implies much less downtime on the plating line.

Plating aluminum likewise uses this innovation. Producing the oxide layer requires snugly managed DC power. High-frequency rectifiers handle the voltage curves flawlessly. This makes certain consistent color and solidity. They function well for both ornamental and safety anodizing jobs. Many markets depend on this capacity.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Rectifier Plating power supply High-frequency rectifiers, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Rectifier Plating power supply High-frequency rectifiers

What is a high-frequency rectifier for plating? It’s a power supply converting AC electricity to DC. This DC current coats metal parts evenly. The high-frequency design uses modern switching tech. Older models rely on heavy transformers. This new version is lighter and smaller.

Why pick high-frequency over traditional rectifiers? They save more energy. They waste less power as heat. Their compact size fits tight workshop spaces. They adjust voltage and current faster. This gives better control over plating thickness.

How do high-frequency rectifiers cut energy costs? Their circuits switch on and off rapidly. This reduces electrical losses. Less heat means cooling systems work less. Overall power use drops by up to 30%. Your electricity bills shrink.

What maintenance do these rectifiers require? Clean dust from vents monthly. Check cooling fans every six months. Tighten wire connections if they loosen. Replace air filters when dirty. No complex servicing is usually needed.

Can they handle different metals like chrome or zinc? Yes. They manage various voltages and currents smoothly. Switch settings between jobs easily. One unit plates jewelry thin parts or thick industrial pieces. They adapt fast.

(Rectifier Plating power supply High-frequency rectifiers)

REQUEST A QUOTE

RELATED PRODUCTS

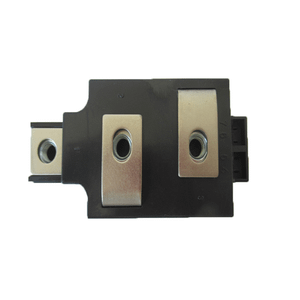

Rectifier screw ZP 200A 300A bolt rotary rectifier diode

rectifiers

RECTIFIER DIODE MODULE PD25016A PD15016A PD25016 PD15016 PC2503

25A 1000V Diode Bridge Rectifier KBU2510

New Original Offer Her508 High Efficiency Rectifier (Do-201ad) 5a 1000v Axial Diode Her508 Her507 Her506