Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

(brake motor rectifier)

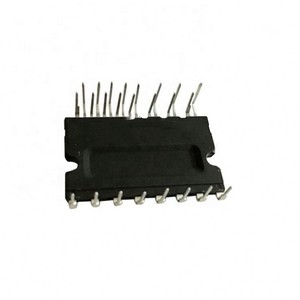

Specification of brake motor rectifier

The brake electric motor rectifier is a crucial part in industrial systems. It transforms air conditioning power to DC power to trigger electro-magnetic brakes rapidly. This makes sure motors stop securely and successfully. The rectifier collaborates with single-phase or three-phase a/c supplies. Input voltage varies from 110V to 480V. Outcome DC voltage adjusts instantly to match the brake coil needs. Existing ability ranges 0.5 A and 20A. This versatility supports different electric motor dimensions and tons.

The tool makes use of high-grade diodes and capacitors. These components manage high rise currents without damage. Thermal monitoring is integrated in. Warm sinks or cooling followers protect against overheating throughout continual usage. Overload security is consisted of. It shuts down the rectifier if existing surpasses secure limits. Short-circuit defense defend against wiring mistakes.

Installation is simple. Terminal blocks enable very easy connection to power and brake coils. Mounting alternatives consist of cacophony rail or panel configurations. Upkeep demands are very little. Regular examination of connections and elements makes certain long-lasting reliability. Dirt or wetness resistance is common. This makes the rectifier ideal for rough environments like manufacturing facilities or exterior sites.

Energy effectiveness is a top priority. The style reduces power loss throughout conversion. This minimizes operating expense. Compatibility covers most brake electric motor brands and versions. Personalized voltage settings are available for specialized applications. Examining satisfies international safety requirements. Certifications include CE, UL, and RoHS.

Sturdiness is ensured via durable building and construction. Products stand up to rust and mechanical stress. The rectifier operates in temperature levels from -20 ° C to 60 ° C. Vibration resistance keeps performance steady in moving machinery. Life expectancy averages ten years under typical problems. Substitute parts are commonly easily accessible. Technical assistance is attended to troubleshooting or upgrades.

The rectifier incorporates efficiently with existing electric motor control systems. Real-time surveillance alternatives are readily available. Users can include sensors or indicators for standing checks. This improves operational transparency. Sound devices stop brake failing during power fluctuations. Feedback time is under 0.1 secs for immediate braking action. Sound levels stay low to avoid interference with various other equipment.

Scalability enables use in tiny makers or big industrial setups. Portable designs save space in congested control panels. Lightweight designs simplify taking care of during installment. Cost-effectiveness balances preliminary investment with long-lasting advantages. Efficiency consistency is verified with rigorous top quality checks. User handbooks consist of circuitry layouts and safety and security standards.

(brake motor rectifier)

Applications of brake motor rectifier

A brake motor rectifier modifications air conditioning power to DC power. This activity triggers the brake system in electric motors. The result fasts, regulated stopping. This part is essential in lots of sectors.

Industrial machinery relies on brake motor rectifiers. Machines need exact stops during production. Conveyor belts or robotic arms stop properly. Products stay clear of damage. Employees remain secure. Production performance boosts.

Elevators use brake electric motor rectifiers daily. Smooth quits at each floor issue. Guests experience marginal jerking. Trip convenience increases. Mechanical wear reduces. Upkeep intervals extend.

Cranes take care of heavy lots. Abrupt stops take the chance of load swings. Brake motor rectifiers make certain progressive braking. Lots stay stable. Accidents lower. Worksite safety and security improves.

Renewable resource systems profit too. Wind generators encounter variable wind speeds. Brake electric motor rectifiers readjust blade turning. Overheating avoids. Generator longevity rises. Energy result supports.

Medical tools needs precision. MRI makers or medical devices require precise positioning. Brake electric motor rectifiers allow immediate stops. Procedures remain exact. Client safety improves.

Transportation markets make use of these rectifiers. Trains or electric automobiles depend upon reputable brakes. Sudden power loss needs quick feedback. Brake electric motor rectifiers supply backup braking. Guest security makes sure.

Textile manufacturing uses high-speed equipments. Abrupt quits prevent fabric tears. Brake motor rectifiers enable instantaneous halts. Product waste minimizes. Production prices decline.

Mining operations involve heavy-duty electric motors. Brake motor rectifiers deal with harsh conditions. Dirt or dampness doesn’t interfere with feature. Equipment downtime reduces. Functional continuity keeps.

Printing machine need precise timing. Paper jams cause hold-ups. Brake motor rectifiers quit rollers precisely. Misfeeds prevent. Publish top quality remains consistent.

Food handling lines prioritize hygiene. Motors quit quickly for cleaning. Brake electric motor rectifiers sustain constant cycles. Sanitation requirements meet. Contamination risks decrease.

Enjoyment trips utilize security brakes. Roller coasters or Ferris wheels require reputable stops. Brake electric motor rectifiers supply instant activity. Cyclist confidence constructs. Event prices drop.

Agricultural machinery encounters irregular terrain. Brake electric motor rectifiers stabilize devices. Sudden inclines or obstacles demand fast stops. Operator safety and security boosts. Plant damages lessens.

Brake motor rectifiers offer diverse demands. They adjust to distinct obstacles. Efficiency boosts. Safety and security prioritizes. Costs lower. Their function in modern innovation stays crucial.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality brake motor rectifier, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of brake motor rectifier

A brake motor rectifier changes AC power to DC power. This lets the brake coil work right. The rectifier ensures the brake engages and releases smoothly. Without it, the motor might not stop properly. This part is key in machinery needing exact stopping control.

How do I know the rectifier is failing? The motor brake might act slow or stick. Overheating is common. You might see burnt smells or sparks. The motor could keep running after power cuts off. Check the rectifier first if these issues happen.

How often should the rectifier be replaced? It depends on use. Heavy use means checking every 6 months. Replace it every 1-2 years. Light use might need checks yearly. Replace every 3-5 years. Look for wear or damage during checks.

Can any rectifier work with my brake motor? No. Match voltage, current, and phase specs. Wrong parts cause poor braking or damage. Check the motor manual for details. Ask the supplier if unsure.

How do I troubleshoot rectifier problems? Test voltage output with a multimeter. No DC output means it’s broken. Check wires for loose connections or burns. Swap with a known-good rectifier to confirm. Replace it if tests show faults.

(brake motor rectifier)

REQUEST A QUOTE

RELATED PRODUCTS

Haney rectifier module telecom power rectifier

High Current 3000A rectifier 12vdc For Gravure Cylinder With IGBT Module

UltraFast MUR460RLG Rectifiers DIODE GEN PURP 600V 4A AXIAL High Performance 600V 4A Axial Diode

auto reverse rectifier 30A for wastewater treatment

DIODE RECTIFIER MODULE DF75BA80 DF50BA80