Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

(50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120)

Specification of 50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120

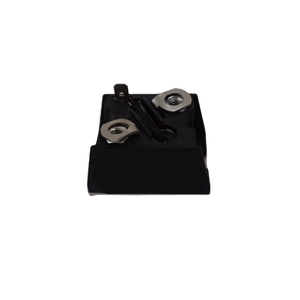

The 50HF120 rectifier diode is built for tough welding machine jobs. It reliably handles high currents. This diode manages 50 amps average forward current. It handles much higher surge currents briefly. The reverse voltage rating reaches 1200 volts. This protects against voltage spikes common in welding circuits.

The diode uses a sturdy stud mount design. This design makes installation simple. It ensures a solid electrical connection. Good thermal management is critical. The stud mount attaches directly to heatsinks. This pulls heat away efficiently. Stable operation under heavy loads depends on this cooling.

Welding machines demand durable parts. The 50HF120 meets this demand. It handles the constant switching and high currents inside welders. Consistent DC output needs good rectification. This diode provides that consistency. A stable welding arc results from steady current flow. Machine reliability increases with quality diodes like this.

The diode’s construction is robust. It withstands the electrical stress of welding environments. Long service life reduces replacement needs. Downtime costs money in industrial settings. This diode helps keep machines running. Its performance ensures dependable welding operations day after day.

Using the correct rectifier matters. The 50HF120 diode (also called 50HFR120) is a proven choice. It fits standard welding machine rectifier assemblies. Proper heatsinking is necessary. Follow the manufacturer’s mounting instructions. Ensure the heatsink surface is clean and flat. Tighten the mounting nut to the specified torque. This guarantees optimal heat transfer and electrical contact.

(50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120)

Applications of 50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120

The 50HF120 rectifier diode handles high current. It is built for tough jobs. Welding machines use it often. These diodes change AC power to DC power. Stable DC power is vital for welding. It makes the welding arc smooth and steady. Good welds need this stability.

The 50HF120 diode manages 50 amps. This is enough power for many welding tasks. It works in different welding machines. MIG welders use these diodes. TIG welders use them too. Stick welders also rely on them. The diode sits inside the machine’s power supply section. Its job is converting power efficiently.

Welding creates intense heat and vibration. The 50HF120 diode is built strong. It handles these harsh conditions well. Its design prevents early failure. This means less machine downtime. Reliability matters in busy workshops. This diode delivers consistent performance.

The 50HFR120 is another name for the same part. It is the identical diode. The specifications match the 50HF120 exactly. Do not get confused by the different labels. Both refer to this robust 50 amp diode.

Using the right diode is critical. The 50HF120 ensures the welder gets stable DC output. Unstable power causes poor weld quality. Spatter increases. Penetration becomes inconsistent. This diode prevents those problems. It keeps the arc focused and controllable. Welders can work faster and better. Repair costs go down. The machine lasts longer. Good diodes save money over time. They are a key part of any welding system.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120

What are 50HF120 rectifier diodes?

These are electrical parts. They control current flow in one direction only. They are designed for high-power uses. They handle big currents and voltages found in welding machines. They change AC power into DC power needed for welding.

Why use them in welding machines?

Welding machines need strong, steady DC current. The 50HF120 diodes do this job well. They handle the high electrical demands. They change the AC power from the wall into DC power for the welding arc. This conversion is essential for good welding performance.

What are the key specs?

Look at the part number: 50HF120. The “50A” means it handles 50 Amps average current. The “1200V” shows it blocks up to 1200 Volts in reverse. They switch power on and off very fast. This fast switching is important for efficiency. They are built tough for industrial settings.

Are they reliable?

Yes, they are known for reliability. They are made for tough jobs like welding. They handle high temperatures and electrical stress well. Their design minimizes power loss. This means less wasted energy and less heat. Using them helps the welding machine last longer.

How do I install them?

Install them correctly. Follow the machine’s wiring diagram. The diode has a cathode and anode end. You must connect these the right way around. Use proper heatsinking. These diodes get hot during operation. Good cooling is vital. Mount them securely on a heatsink. This keeps them cool and working properly.

(50HF120 50a rectifier diodes For Welding Machine 50HFR120 diodo rectificador 50hf120)

REQUEST A QUOTE

RELATED PRODUCTS

New And 100% Origail Rectifier Module DPR-4850-D-DCE

Original New Product SS110 1A Integrated Circuit Rectifier Diode Quality Assured with 3W Max Power LED Type Hole Case

Cheng You MBR30100PT 30100 MBR30100 30A 100V TO-247 Schottky Rectifier Diode China Dioes High quality

Diode Bridge Rectifier KBL410 Bridge Rectifier

BAS21VD rectifier