Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

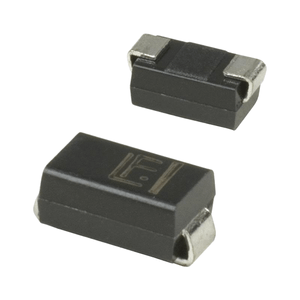

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

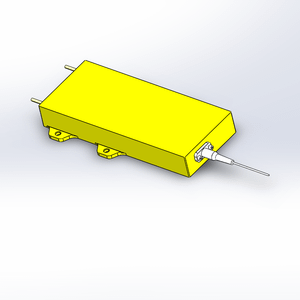

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)

Specification of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This 12V 1500A high power electroplating rectifier provides severe existing for demanding plating jobs. It gives a stable 12 volts DC result. The system takes care of approximately 1500 amps continually. Air air conditioning keeps everything running cool also under hefty lots. Followers draw air over interior parts. This design stays clear of overheating throughout lengthy plating cycles. Upkeep stays straightforward without fluid coolant systems.

An integrated timing feature is a significant advantage. Operators established specific plating durations straight on the device. The rectifier immediately turns off after the set time. This makes certain regular layer thickness each time. It stops over-plating blunders. Workers do not require to constantly view the clock. Productivity improves significantly.

The rectifier supplies uncomplicated procedure. Controls are clear and easy to use. Readjust voltage and present setups with easy handles or switches. Review outputs on clear digital displays. Establishing the timer is just as basic. New customers learn it rapidly. Arrangement calls for very little training.

Safety and integrity are core features. The design includes defense against overloads and brief circuits. This safeguards both the tools and the plating bath. The system utilizes robust industrial-grade components. These parts stand up to rough plating store atmospheres. The steel unit withstands rust. It likewise protects against dirt and dampness ingress. Electric safety accreditations are standard.

This power supply fits massive electroplating procedures. It deals with huge parts or high-volume barrel layering effectively. The high amperage guarantees quick deposition rates. Constant outcomes minimize product waste. The timing function includes vital process control. Manufacturing facilities see far better throughput and reduced costs.

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)

Applications of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This effective 12V 1500A electroplating rectifier delivers serious power for demanding commercial procedures. It provides stable, high-current DC outcome vital for constant metal deposition. The incorporated timing function is a major benefit. Operators set exact plating periods for each batch. This automation guarantees repeatable results batch after batch. It eliminates uncertainty. It boosts product consistency substantially.

Air cooling maintains the system running reliably under hefty tons. Followers dissipate warmth efficiently. This layout avoids intricate liquid cooling systems. Upkeep stays easier. Downtime decreases. The robust construction takes care of challenging factory settings. It stands up to warmth, dirt, and vibration common in layering stores.

This rectifier masters high-throughput electroplating applications. It’s excellent for plating big surface areas promptly. Think auto components, heavy machinery components, or large steel fixtures. The high 1500A capacity handles thick down payments successfully. It matches difficult chromium plating, nickel plating, and copper plating procedures requiring significant power. The secure outcome keeps consistent present density. This leads to attire, high-grade metal coverings.

The timer feature automates the plating cycle. Employees load components. They begin the process. The device competes the set time. It then turns off instantly. This avoids over-plating. It conserves power. It optimizes bathroom life. It releases operators for other tasks. Accuracy timing makes sure every part gets exactly the appropriate layer density.

Integrity is crucial in production. This air-cooled design uses reliable operation. Regular DC result protects against layer problems. Integrated defense circuits guard against overloads and shorts. This shields your important workpieces. It safeguards the rectifier itself. The unit gives the muscle needed for industrial-scale electroplating. Its timing feature adds crucial procedure control.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

What is this rectifier used for? This rectifier powers industrial electroplating and electrolysis. It delivers stable DC power. Factories use it for metal coating tasks. It handles chrome, nickel, zinc plating. It manages heavy-duty operations smoothly. It fits large-scale production needs.

What are the key features? It supplies 12 volts and 1500 amps. This offers robust power for demanding jobs. It includes a built-in timing function. This controls process duration precisely. It uses air cooling technology. Air cooling simplifies the setup. It avoids water-based systems entirely. This reduces maintenance efforts. It ensures long-term reliability. It saves factory floor space too.

How does the timing function work? Set the desired time upfront. Choose hours, minutes, or seconds. The unit runs for that exact period. It shuts down automatically afterward. This guarantees uniform plating results. It minimizes energy waste. It removes timing mistakes. Workers handle other duties during operation.

Why choose air cooling? Air cooling relies on internal fans. Fans circulate air through the machine. This dissipates heat effectively. It beats water cooling in simplicity. No plumbing or water supply is necessary. It cuts operational expenses. It performs in arid or gritty environments. It resists freezing in cold climates. It provides consistent cooling always.

What safety measures are included? Multiple safeguards are integrated. Overload protection interrupts power during excessive current. Short-circuit protection responds instantly to faults. Over-temperature protection switches off the unit if overheated. These features prevent equipment damage. They shield workers from harm. The design prioritizes workplace safety. The construction ensures durability.

(12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier)

REQUEST A QUOTE

RELATED PRODUCTS

HER501 HER502 HER503 HER504 HER505 HER506 HER507 HER508 5A RECTIFIER DIODE

DF50AA160 Bridge Rectifier Module 1600V 50A bom service

auto reverse rectifier 30A for wastewater treatment

SBAS40-04LT1G Automotive Schottky Diodes 40V TR Rectifiers SHKY DIO High Performance Product

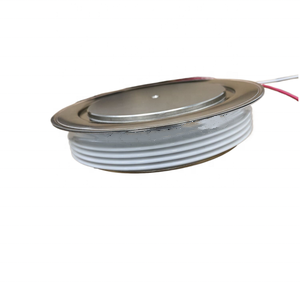

25F120 rectifier diode stud type