Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Phase Control Thyristor

A phase control thyristor, often referred to as a triac or SCR (Silicon Controlled Rectifier) in certain applications, is a semiconductor device used for controlling the amount of power delivered to a load by adjusting the phase angle at which the AC waveform is allowed to conduct. This method of control is known as phase angle control or simply phase control. Phase control thyristors are widely used in various applications that require precise regulation of electrical power, such as lighting dimmers, motor speed controls, temperature controllers, and more.

Features of Phase Control Thyristor

Phase Angle Control: Allows adjustment of the conduction point within each half-cycle of the AC waveform, enabling precise control over the average power delivered to the load.

High Efficiency: Operates with minimal losses when conducting, providing efficient power control.

Bidirectional Conductivity (Triacs): For AC applications, triacs can conduct current in both directions, making them suitable for full-wave control of AC loads.

Unidirectional Conductivity (SCRs): SCRs conduct current in one direction only and are typically used for half-wave control of AC or DC loads.

Gate Triggering: Conduction begins when a small current is applied to the gate terminal, allowing for easy control of the turn-on point.

Latching Current: Once triggered, the thyristor continues to conduct until the current through it falls below a certain level called the holding current.

Temperature Sensitivity: Performance can be affected by temperature changes, requiring thermal management considerations in design.

Voltage and Current Ratings: Available in a wide range of voltage and current ratings to suit different application needs.

Noise Generation: Can generate electromagnetic interference (EMI), necessitating proper filtering and shielding in sensitive applications.

Protection Mechanisms: Often include built-in protection against overvoltage and overcurrent conditions to safeguard the device and connected systems.

(Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A)

Specification of Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A

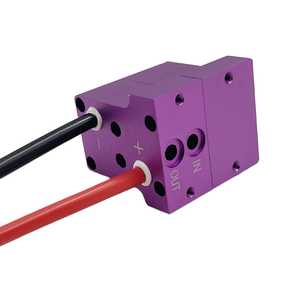

The Stud Phase Control Thyristor SCR 1600V KP50A (KP100A, KP200A) is developed for high-power phase control applications. It manages voltages up to 1600V and currents varying from 50A to 200A. This part fits industrial systems requiring precise policy of air conditioning power. The stud-mounted design makes sure solid mechanical security and reliable warm dissipation.

The thyristor features a high rise current capability. It stands up to abrupt overloads without damages. The forward obstructing voltage of 1600V makes it reputable in high-voltage environments. The gate trigger current is reduced, making certain smooth activation. This decreases power loss during procedure.

Thermal performance is vital. The tool runs efficiently at junction temperatures as much as 125 ° C. Correct mounting on a heatsink is essential for optimal thermal management. The stud link streamlines installment in high-current circuits. Copper or aluminum heatsinks are advised.

Applications consist of electric motor rate control, power materials, and illumination systems. It is likewise made use of in commercial heating devices and voltage regulators. The thyristor’s durable building and construction makes certain sturdiness in severe conditions. It resists vibration and mechanical anxiety.

Electrical characteristics correspond across the KP series. Reverse blocking voltage matches the forward ranking. Leakage currents continue to be very little under regular procedure. Turn-off time is fast, improving changing performance. This minimizes delays in phase-controlled systems.

Gate control calls for a brief pulse for trustworthy triggering. Pulse duration must surpass 10 microseconds. Eviction voltage should remain within defined limitations to avoid damages. Proper gateway drive circuits improve performance.

The KP50A, KP100A, and KP200A share comparable mechanical measurements. Weight differs slightly with current score. All variations consist of a passivated surface for corrosion resistance. Storage space conditions need to prevent excess moisture or temperature level extremes.

Checking validates conformity with industry requirements. Each unit undergoes extensive quality checks. Electrical specifications are validated under simulated operating conditions. This makes certain dependability before shipment.

Customers have to comply with taking care of standards. Static-sensitive safety measures apply during installation. Over-tightening placing equipment can damage the stud terminal. Adequate insulation is needed for high-voltage arrangements. Right electrical wiring stops accidental brief circuits.

The thyristor’s design prioritizes long life. Routine maintenance checks are recommended. Cleaning the heatsink and terminals avoids dust accumulation. Monitoring operating temperatures helps stay clear of thermal runaway. Appropriate usage prolongs the element’s service life.

Compatibility with common phase control circuits streamlines integration. Designers can change older thyristors without revamping systems. Technical assistance is available for application-specific inquiries. Datasheets provide in-depth electrical and mechanical requirements.

(Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A)

Applications of Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A

The Stud Phase Control Thyristor SCR 1600V KP50A (and higher-current models KP100A, KP200A) is a high-power semiconductor gadget created for accurate control of electric tons popular industrial settings. This thyristor takes care of approximately 1600 volts and supports present ratings from 50A to 200A. Its stud-mounted layout ensures strong thermal efficiency and mechanical stability.

These thyristors are frequently utilized in motor rate control systems. They change power circulation to motors by handling phase angles. This enables smooth velocity and deceleration in equipment like conveyor belts or commercial fans. The high voltage rating makes them suitable for durable devices operating in rough problems.

Another application is in power policy for heating unit. The thyristor controls current flow to repellent tons like heaters or ovens. This maintains consistent temperature levels without overshooting targets. The device’s dependability ensures long-term operation in high-temperature environments.

They are likewise effective in air conditioning voltage stabilizers. By readjusting transmission angles, the thyristor corrects voltage variations in genuine time. This safeguards delicate devices from damage caused by unpredictable power supplies. The fast switching ability reduces action hold-ups.

The KP50A, KP100A, and KP200A designs are ideal for welding equipments. They take care of the high currents needed for arc welding. Their tough building stands up to frequent surges and vibrations. This lowers downtime in manufacturing settings.

These thyristors function well in lights control systems for large venues. They dim or brighten high-intensity lights by modulating power delivery. The phase control method stays clear of flickering and guarantees smooth shifts.

The stud-type package gives effective warm dissipation. This prevents overheating also during continuous operation. The durable layout resists mechanical stress and anxiety and electrical sound. This makes the thyristor appropriate for use in mining, metal handling, or renewable resource systems.

Engineers prefer these gadgets for their simplicity and toughness. No complicated wiring is needed for fundamental phase control tasks. Maintenance requirements are reduced compared to different options. The thyristor’s efficiency stays steady throughout a vast temperature level array.

Compatibility with common warmth sinks and mounting equipment simplifies setup. Customers can upgrade existing systems without redesigning entire configurations. This flexibility lowers prices and downtime throughout retrofits.

The 1600V rating future-proofs systems versus higher voltage demands. Industries embracing automation or energy-efficient innovations take advantage of this scalability. These thyristors bridge the void in between conventional power control techniques and modern-day industrial demands.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A

The Stud Phase Control Thyristor SCR 1600V KP50A (and KP100A/KP200A) is a high-power semiconductor device for controlling electrical power in industrial systems. Below are common questions about its use and features.

What is this thyristor used for?

It controls AC power in circuits requiring precise phase-angle adjustments. The device handles high voltage and current levels. It acts as a switch for power regulation in motor controllers, heating systems, or lighting controls.

What applications suit the 1600V rating?

The 1600V blocking voltage makes it ideal for heavy-duty industrial equipment. Examples include high-voltage rectifiers, industrial motor drives, or power converters. It supports systems where voltage spikes or surges are common.

What do KP50A, KP100A, and KP200A mean?

These codes show the average forward current ratings. KP50A handles 50A, KP100A manages 100A, and KP200A supports 200A. Choose the model based on your system’s current requirements. Higher current ratings suit larger loads.

How is the thyristor installed safely?

Mount it securely using proper stud hardware. Follow torque specifications to avoid damage. Use thermal paste and heatsinks for heat dissipation. Ensure electrical contacts are clean and tight. Incorrect installation risks overheating or failure.

What precautions prevent device failure?

Avoid exceeding voltage or current limits. Use protective circuits against voltage spikes. Maintain stable temperatures with cooling systems. Test the device under controlled conditions before full deployment. Check insulation regularly to prevent short circuits.

The thyristor’s rugged design ensures reliability in demanding environments. Proper selection and maintenance extend its operational lifespan. Matching the model to system requirements guarantees optimal performance.

(Stud Phase Control Thyristor SCR 1600V KP50A (Stud Phase Control Thyristor SCR 1600V KP100A KP200A)

REQUEST A QUOTE

RELATED PRODUCTS

Hitachi Energy ABB PCT 5STP 25M5200 Original Phase Control Thyristor Semiconductor Silicon Wafer Material

TO-65 50RIA 50A 1200V 1600V Phase Control Thyristor Stub version

SCR Phase Control Thyristor F5SGF3045J0022 Thyristor Rectifier Diode Module

Phase Control Discrete Stud Thyristor SCR 20RIA 50RIA 80RIA 50RIA120 50RIA160

SCR System Disc Thyristor Phase Control Modules for DC and AC Motor Inverter Triac Thyristor Application