Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of High Frequency Thyristors

High Frequency Thyristors are specialized semiconductor devices designed to operate at higher frequencies than conventional thyristors. They are used in applications requiring rapid switching, such as high-frequency heating, motor control, and power supplies. These devices can handle significant electrical power while providing efficient and reliable switching performance at frequencies that extend beyond the typical operating range of standard thyristors.

Features of High Frequency Thyristors

High Switching Speed: Capable of operating at much higher frequencies compared to traditional thyristors, making them suitable for fast-switching applications.

Efficient Power Handling: Designed to manage substantial electrical power with minimal losses during switching operations.

Low Gate Trigger Current: Require less current to trigger the switching action, enhancing efficiency and reducing heat generation.

Rugged Construction: Built to withstand harsh environments and thermal stress, ensuring reliable operation over time.

Compact Size: Offer a smaller footprint compared to lower-frequency counterparts, which is beneficial for compact designs.

Improved dv/dt Capability: Enhanced capability to handle rapid voltage changes without spurious turn-on, contributing to more stable operation.

Reduced EMI: Lower electromagnetic interference due to optimized design, which is crucial for sensitive applications.

Versatile Applications: Suitable for a wide range of industries including automotive, industrial automation, telecommunications, and renewable energy systems.

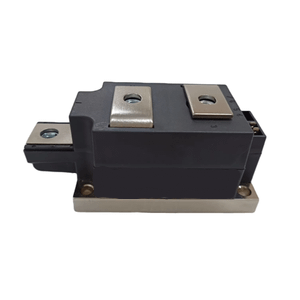

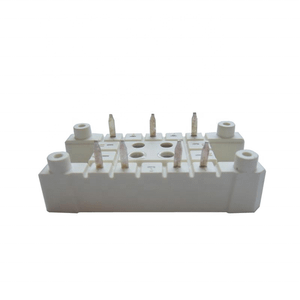

(TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor)

Specification of TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor

This TTB6C135N16LOF is a bridge rectifier component. It makes use of high-frequency thyristors. It converts air conditioning power into DC power. It’s constructed for requiring control tools applications. The component takes care of high currents successfully.

Its essential requirements is the ordinary forward current rating. It manages 135 Amps constantly. The top recurring reverse voltage is 1600 Volts. This voltage rating makes certain trusted blocking. It stops reverse existing flow effectively. The module stands up to high rise currents. It takes care of non-repetitive surge comes to a head up to 1350 Amps. This safeguards versus unanticipated power spikes.

Thermal administration is important. The component creates warmth throughout procedure. You must place it on a heatsink. Correct heatsinking maintains temperatures secure. The maximum operating junction temperature level is 125 levels Celsius. Exceeding this limitation risks damages. Excellent cooling expands the module’s life expectancy.

Triggering the thyristors calls for specific gateway signals. Eviction trigger voltage is low. It typically needs just 1.5 Volts. Eviction trigger current is likewise reduced. It usually calls for simply 100 milliAmps. These low trigger degrees streamline control circuit design. Turn-on time is fast. This makes sure fast feedback throughout switching cycles.

Electric seclusion is important for safety. The module provides isolation between the circuit and the base plate. Its seclusion voltage ranking is 2500 Volts RMS. This protects versus dangerous potential distinctions. The component makes use of stud installing. This supplies a solid mechanical connection. It also makes certain excellent thermal transfer to the heatsink. The stud itself is electrically separated. This avoids basing concerns.

(TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor)

Applications of TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor

The TTB6C135N16LOF is an effective control devices bridge rectifier component. It makes use of high-frequency thyristor modern technology. This component changes alternating current (A/C) right into direct existing (DC). It’s developed for requiring industrial tasks. The component takes care of high voltages and huge currents well. Its layout ensures steady DC result. Stable power is critical for sensitive tools.

This rectifier component locates use in many areas. Manufacturing facilities count on it for motor drives. Electric motors need smooth DC power. The module offers this. It’s crucial in power products for large devices. Uninterruptible Power Material (UPS) utilize it also. These systems safeguard versus power loss. Dependable rectification keeps backup power ready. Welding equipment frequently incorporates this component. Welding requires solid, regulated DC current. This module provides that power effectively.

Power transmission systems take advantage of it. It helps handle high-voltage DC (HVDC) web links. HVDC moves power over long distances. This component regulates the conversion factors. Renewable energy configurations like wind turbines use it. Solar inverters likewise rely on such parts. They convert variable AC right into useful DC. Industrial furnace need exact power control. This rectifier module enables that control. Battery billing terminals utilize it for quickly billing. Fast charging requires high-power DC conversion.

The TTB6C135N16LOF excels in tough problems. It operates accurately at high frequencies. High regularity enables smaller, lighter layouts. Its thermal management is durable. Warmth is a major adversary of electronic devices. This component deals with warm properly. Its building utilizes solid products. This makes sure lengthy life span. Industrial atmospheres are extreme. Vibration, dust, and temperature swings occur. This component endures these difficulties. It supplies consistent efficiency with time. Maintenance demands are reduced. Downtime expenses money. Dependability conserves money.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor

This part changes AC electricity to DC electricity. It handles high power levels. Industries use it in motor drives, power supplies, and industrial control systems. It works reliably at high switching speeds.

What does the TTB6C135N16LOF module do?

It converts alternating current (AC) into direct current (DC). This conversion is essential for many electronic devices needing steady DC power. The module combines multiple thyristors to achieve this efficiently.

Where is this rectifier module typically used?

You find it in demanding industrial settings. Common applications include motor speed controllers, large power supply units, and automated factory equipment. It handles tough conditions like heat and electrical noise.

Why choose this specific module over others?

Its key strength is high-frequency operation. Many standard rectifiers struggle above 50/60Hz. This module manages much higher switching frequencies smoothly. This makes it suitable for modern, efficient power electronics designs.

How do I install this module correctly?

Mount it firmly onto a suitable heatsink. Good thermal contact is critical. Use thermal paste or a pad. Connect the power terminals securely. Ensure proper electrical isolation. Follow the manufacturer’s torque specs for screws. Poor mounting causes overheating and failure.

What precautions are needed during operation?

Watch the temperature. Keep it within the specified limits. Use adequate cooling. Check voltage and current stay below the maximum ratings. Avoid voltage spikes. Consider snubber circuits for inductive loads. Protect against short circuits. Regular inspection helps spot potential issues early.

(TTB6C135N16LOF Control Equipment Bridge Rectifier Module High Frequency Thyristor)

REQUEST A QUOTE

RELATED PRODUCTS

High Frequency Welding Machine Oscillator Triode 7T69RB

PFU-3 network power supply high frequency charging rectifier module

new original high frequency authentic high power thyristor SCR module KK2500A2500V KK2500A/2500V KK2500-25

ZXD2400 (V3.0) network power supply high frequency charging rectifier module

new original high frequency authentic high power thyristor SCR module KP7 300-22 KP7 300A2200V KP7 300-22