Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

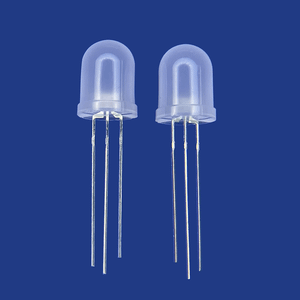

Overview of High Frequency Thyristors

High Frequency Thyristors are specialized semiconductor devices designed to operate at higher frequencies than conventional thyristors. They are used in applications requiring rapid switching, such as high-frequency heating, motor control, and power supplies. These devices can handle significant electrical power while providing efficient and reliable switching performance at frequencies that extend beyond the typical operating range of standard thyristors.

Features of High Frequency Thyristors

High Switching Speed: Capable of operating at much higher frequencies compared to traditional thyristors, making them suitable for fast-switching applications.

Efficient Power Handling: Designed to manage substantial electrical power with minimal losses during switching operations.

Low Gate Trigger Current: Require less current to trigger the switching action, enhancing efficiency and reducing heat generation.

Rugged Construction: Built to withstand harsh environments and thermal stress, ensuring reliable operation over time.

Compact Size: Offer a smaller footprint compared to lower-frequency counterparts, which is beneficial for compact designs.

Improved dv/dt Capability: Enhanced capability to handle rapid voltage changes without spurious turn-on, contributing to more stable operation.

Reduced EMI: Lower electromagnetic interference due to optimized design, which is crucial for sensitive applications.

Versatile Applications: Suitable for a wide range of industries including automotive, industrial automation, telecommunications, and renewable energy systems.

(Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace)

Specification of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

This compact high-frequency melting furnace is constructed for performance. It thaws scrap steel quickly. You can refine steel, copper, light weight aluminum, also gold. The small size fits easily in workshops. It does not require much space. The furnace makes use of high-frequency induction home heating. This approach is very reliable. It heats steel directly inside the crucible. Energy loss is minimal. You conserve power. Thawing occurs promptly. You see results in mins, not hours.

Capacity alternatives are practical. Typical sizes hold 1kg to 5kg of metal. Pick the dimension matching your requirements. The crucible is solid. It takes care of high temperatures well. Substitute is straightforward. Operation is straightforward. Controls are basic. Establish the temperature. Establish the timer. The heating system does the work. Digital presents reveal the present condition clearly. You see the temperature level. You see the time remaining. Security is essential. The device includes get too hot security. It closes down immediately if needed. The housing remains awesome throughout operation. You stay clear of burns. The furnace is reputable for day-to-day usage.

Maintenance is very easy. Keep the device tidy. Check the links regularly. The layout is robust. It withstands workshop problems. This furnace is suitable for little shops. Jewelers use it for precious metals. Hobbyists cast detailed parts. Colleges use it for demos. It thaws metal cleanly. Slag formation is minimized. You obtain top quality molten steel. The financial investment pays off quickly. Manufacturing prices drop. This device enhances your metalworking capability dramatically.

(Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace)

Applications of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

These compact high-frequency melting heaters change exactly how tiny workshops take care of steel. They thaw scrap quickly and successfully. Forget cumbersome traditional tools. These mini heating systems use electromagnetic induction. Warm develops inside the metal itself. This technique is extremely quick. You get molten metal ready in minutes, not hours. It saves significant energy and time.

Work with many metals. Thaw scrap steel successfully. Manage copper and brass alloys conveniently. Light weight aluminum scrap thaws perfectly too. Rare-earth elements like silver and gold are no problem. The specific temperature control is essential. You set the exact warm required. This makes certain tidy melts each time. You obtain regular outcomes batch after batch.

These heating systems are excellent for tiny shops. Jewelers enjoy them for casting great items. Hobbyists locate them ideal for home jobs. Educational laboratories utilize them for presentations. They fit conveniently on a durable bench. Their little impact saves valuable shop space. Procedure is straightforward. Load your scrap steel right into the crucible. Select your program or set the temperature level. After that start the melting cycle. The heating system does the rest.

Rate is a major benefit. Induction home heating is direct and powerful. There’s no slow-moving pre-heating stage. You go from solid scrap to putting liquid steel quickly. Temperature level precision is excellent. This prevents burning delicate alloys. It likewise makes sure the ideal melt for excellent casting flow. Control the process specifically. This brings about higher quality castings and much less waste.

Energy efficiency issues. Induction technology focuses warm directly on the metal charge. Much less warmth runs away into the air. This lowers your electricity expenses. The process is likewise cleaner general. You handle much less oxidation loss. Your beneficial metal stays in the crucible. Crucible selections are essential. Use graphite crucibles for brass or copper. Usage ceramic crucibles for aluminum. Suit the crucible to your metal for best results. These heaters offer real power and precision in a little plan.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

Small High Frequency Melting Furnace FAQs

What metals can this small furnace melt?

This furnace melts scrap metal. It handles steel, copper, aluminum, and even gold. Different metals need different melting temperatures. The furnace reaches high heat levels fast. This makes it versatile for various projects.

How much metal can it melt at once?

Capacity depends on the crucible size. Crucibles hold the molten metal. Common sizes are 1kg, 2kg, and 3kg. Choose the crucible based on your project needs. The furnace body itself is small. It fits easily in workshops or garages.

What crucible should I use?

Use graphite or ceramic crucibles. The right crucible depends on the metal you melt. Graphite works well for copper and aluminum. Ceramic is better for steel. Match the crucible to the metal type and temperature. Crucibles wear out over time. Replace them when they crack or thin.

What power supply does it need?

This furnace uses standard electricity. It typically needs 220V power. Check the specific model’s voltage requirements. High frequency melting is efficient. It heats metal quickly with less energy waste. Ensure your workshop has the correct power outlet.

Does it need water cooling?

Yes, water cooling is essential. The furnace generates intense heat. Water flows through the coil to prevent overheating. Never run the furnace without the water cooling system connected. This protects the equipment. Use clean water and check the flow regularly.

(Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

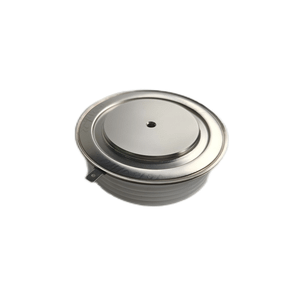

Original Electronic Component High frequency thyristor module KP4000A

High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine

FC0603E50R0BTBST1 (CHY BOM Service) 0603 FC High Frequency Surface Mount Chip Resistor FC0603E50R0BTBST1

ZXDU75-BACK020400 network power supply high frequency charging rectifier module

high frequency authentic high power thyristor SCR module KP3000A3000V KP3000-30 KP3000A-3000