Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

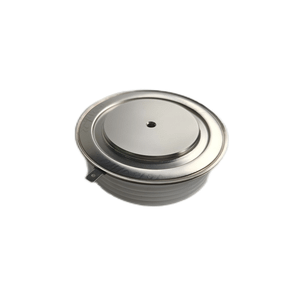

Overview of High Frequency Thyristors

High Frequency Thyristors are specialized semiconductor devices designed to operate at higher frequencies than conventional thyristors. They are used in applications requiring rapid switching, such as high-frequency heating, motor control, and power supplies. These devices can handle significant electrical power while providing efficient and reliable switching performance at frequencies that extend beyond the typical operating range of standard thyristors.

Features of High Frequency Thyristors

High Switching Speed: Capable of operating at much higher frequencies compared to traditional thyristors, making them suitable for fast-switching applications.

Efficient Power Handling: Designed to manage substantial electrical power with minimal losses during switching operations.

Low Gate Trigger Current: Require less current to trigger the switching action, enhancing efficiency and reducing heat generation.

Rugged Construction: Built to withstand harsh environments and thermal stress, ensuring reliable operation over time.

Compact Size: Offer a smaller footprint compared to lower-frequency counterparts, which is beneficial for compact designs.

Improved dv/dt Capability: Enhanced capability to handle rapid voltage changes without spurious turn-on, contributing to more stable operation.

Reduced EMI: Lower electromagnetic interference due to optimized design, which is crucial for sensitive applications.

Versatile Applications: Suitable for a wide range of industries including automotive, industrial automation, telecommunications, and renewable energy systems.

(High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine)

Specification of High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine

The high-frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine delivers precise performance for industrial welding tasks. This machine uses advanced high-frequency inverter technology to generate stable welding currents. The design focuses on efficiency. It handles various materials like stainless steel, copper, aluminum, and alloy wires. The tungsten rod electrode ensures minimal wear. This extends the equipment’s lifespan. The automatic wire mesh feeding system reduces manual intervention. It improves production speed.

The machine operates with adjustable high-frequency current settings. Users control welding intensity based on material thickness or type. The electronic components are built for durability. They withstand prolonged use in demanding environments. The spot welding process produces consistent, clean joints. It avoids common issues like overheating or material distortion. The cooling system prevents thermal damage. It maintains stable operation during extended sessions.

Safety features include overload protection and automatic shutdown mechanisms. These prevent equipment failure. The user interface is simple. Operators adjust parameters quickly via a digital control panel. Real-time monitoring displays voltage, current, and temperature data. This ensures transparency during operations.

The machine suits applications in automotive parts manufacturing, electronic component assembly, and metal mesh production. It handles thin to medium-thickness materials effectively. The compact structure saves workspace. Installation requires minimal setup. Maintenance involves routine checks of electrodes and cooling components.

Technical specifications include an input voltage range of 220V-380V, output frequency of 10kHz-50kHz, and maximum welding thickness of 3mm. The tungsten rod diameter is 3mm-6mm. The unit weighs approximately 120kg. Dimensions are 800mm x 600mm x 1000mm. Power consumption remains low due to energy-efficient inverter technology. Noise levels stay below 70dB during operation.

(High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine)

Applications of High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine

High-frequency inverter electronic component spot welding machines with tungsten rods are essential tools in modern manufacturing. These machines use advanced technology to join metal parts quickly. They work by generating high-frequency currents. The currents create intense heat at the welding point. Tungsten rods are used because they handle high temperatures well. This makes the welding process stable.

These machines are widely used in electronics production. They assemble circuit boards and tiny components. The precision of the tungsten rods ensures minimal damage to sensitive parts. Automotive industries rely on them for welding battery packs in electric vehicles. The process is fast. It maintains strong connections in critical systems.

Aerospace manufacturing benefits from these machines too. They weld thin metal sheets and wires in aircraft components. The automatic wire mesh welding feature speeds up production. It ensures consistency in large batches. Medical device makers use them to create surgical tools and implants. Clean, precise welds are vital here. The machines reduce contamination risks.

Renewable energy sectors use these welders for solar panels and wind turbines. They connect conductive wires without weakening materials. The high-frequency inverter saves energy. It lowers operational costs over time. Repair workshops find the machines useful. They fix small metal items like jewelry or electronics. Adjustable settings make them versatile for different tasks.

The automatic wire mesh welding function handles complex patterns. It reduces manual labor. Workers can focus on quality checks. The machines are durable. They require minimal maintenance. Training operators is straightforward. This cuts downtime in factories.

Industries choose these machines for reliability. They improve production rates. They ensure consistent weld quality. The technology adapts to new materials. This future-proofs manufacturing setups. High-frequency inverter systems are compact. They fit into tight workshop spaces. Noise levels are low. This creates a better work environment.

Tungsten rods last longer than other materials. Replacement costs stay low. The machines comply with safety standards. They reduce workplace hazards. Businesses see a return on investment quickly. Productivity gains offset initial costs. These welding solutions meet the demands of high-tech industries. They support innovation in product design.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine

High-frequency inverter electronic component spot welding machines use tungsten rods for automatic wire mesh welding. These machines handle precise spot welding tasks in electronics and metalwork. Below are answers to common questions about this equipment.

What is the main use of this spot welding machine? The machine joins thin metal sheets or wires in electronics, automotive parts, or wire mesh production. It creates strong, consistent welds without damaging surrounding materials. The high-frequency inverter ensures quick energy transfer for efficient operation.

How does the high-frequency inverter improve welding quality? The inverter converts power to a stable high-frequency current. This allows precise control over heat input. It reduces overheating risks. Weld points stay clean and solid. The system adapts to different material thicknesses automatically.

Why choose tungsten rods for the welding electrodes? Tungsten withstands extreme temperatures without wearing down fast. It keeps its shape during repeated use. This ensures uniform pressure on weld points. Tungsten rods last longer than copper or alloy electrodes. Replacement costs drop over time.

Can this machine weld different materials? Yes. It works well on steel, copper, aluminum, and mixed alloys. Users adjust current settings based on material type and thickness. The automatic wire feed handles various wire diameters. This flexibility suits factories producing diverse products.

What maintenance does the machine need? Clean electrodes and wire feed mechanisms regularly. Check electrical connections for tightness. Replace worn tungsten rods when surface cracks appear. Lubricate moving parts monthly. Follow the manual’s schedule for inverter cooling system checks. Proper care prevents downtime and extends machine life.

(High frequency inverter electronic component spot welding tungsten rod automatic wire mesh welding machine spot welding machine)

REQUEST A QUOTE

RELATED PRODUCTS

PS48300-3/1800-Y3 network power supply high frequency charging rectifier module

high frequency authentic high power thyristor SCR module KP8 600-40 KP8600-40 KP8 600-40

ZXDU75-BACK020400 network power supply high frequency charging rectifier module

ER2834-1 Factory High Frequency Transformer For Telecommunications Infrastructure And Solutions

Electronic Equipments Phase Control Thyristor Scr High Frequency Thyristor SW22PHN380