Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

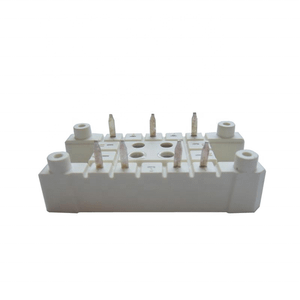

Overview of High Frequency Thyristors

High Frequency Thyristors are specialized semiconductor devices designed to operate at higher frequencies than conventional thyristors. They are used in applications requiring rapid switching, such as high-frequency heating, motor control, and power supplies. These devices can handle significant electrical power while providing efficient and reliable switching performance at frequencies that extend beyond the typical operating range of standard thyristors.

Features of High Frequency Thyristors

High Switching Speed: Capable of operating at much higher frequencies compared to traditional thyristors, making them suitable for fast-switching applications.

Efficient Power Handling: Designed to manage substantial electrical power with minimal losses during switching operations.

Low Gate Trigger Current: Require less current to trigger the switching action, enhancing efficiency and reducing heat generation.

Rugged Construction: Built to withstand harsh environments and thermal stress, ensuring reliable operation over time.

Compact Size: Offer a smaller footprint compared to lower-frequency counterparts, which is beneficial for compact designs.

Improved dv/dt Capability: Enhanced capability to handle rapid voltage changes without spurious turn-on, contributing to more stable operation.

Reduced EMI: Lower electromagnetic interference due to optimized design, which is crucial for sensitive applications.

Versatile Applications: Suitable for a wide range of industries including automotive, industrial automation, telecommunications, and renewable energy systems.

(CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V)

Specification of CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V

The CUT-200CNC 380V is a high-frequency commercial plasma reducing maker designed for accuracy steel cutting. It operates a 380V power supply, making it appropriate for durable commercial use. The maker integrates advanced CNC modern technology, making certain exact control over reducing paths. This design supports materials like steel, stainless steel, aluminum, and copper, with a maximum cutting density of 50mm.

The plasma lantern uses high-frequency arc ignition, making it possible for quick starts and steady performance. The system includes a built-in air compressor, streamlining configuration and minimizing exterior tools needs. The CNC controller includes an easy to use interface, permitting operators to input styles through USB or straight programming. Compatibility with CAD/CAM software application enhances the conversion of electronic layouts right into cutting commands.

Safety and security attributes consist of overload security, voltage stablizing, and automatic shutdown in situation of uncommon currents. The maker’s framework is constructed from enhanced steel, providing durability under high workloads. A dual-axis drive system ensures smooth activity control, decreasing errors during facility cuts. The worktable is flexible, suiting materials of differing sizes and shapes.

Cutting speed ranges from 200 to 4000mm per min, adjustable based upon material kind and density. The maker’s duty cycle reaches 60% at 200A, ideal for long term operation. It generates very little slag, decreasing post-processing time. The lantern height control instantly adapts to preserve ideal range from the workpiece, enhancing cut top quality.

Maintenance is straightforward, with obtainable elements and clear analysis signs. Regular maintenance includes cleaning the torch, examining air filters, and evaluating electric connections. The CUT-200CNC 380V is optimal for industries like automotive manufacture, building and construction, and steel art. Its compact layout conserves workshop room while providing industrial-grade performance.

Technical requirements include a ranked input current of 45A, 200A outcome current, and a working voltage series of 100-200V. The maker evaluates 280kg, making certain security during procedure. Sound degrees remain below 75dB, abiding by office safety requirements. Optional add-ons include a water-cooling system for expanded usage and a rotating attachment for round reducing jobs.

The system sustains several languages on the control panel, dealing with varied functional teams. Training resources and consumer assistance are available to aid with arrangement and troubleshooting. This model balances performance, reliability, and cost-effectiveness for services looking for sophisticated metal-cutting solutions.

(CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V)

Applications of CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V

The CUT-200CNC 380V CNC high-frequency commercial plasma cutting maker manages metal construction tasks with rate and accuracy. It works well for cutting steel, light weight aluminum, stainless steel, and other conductive steels approximately 20mm thick. This machine fits factories, workshops, and large-scale manufacturing units requiring trustworthy performance.

The vehicle industry uses this equipment to create parts like chassis components, exhaust systems, and braces. It ensures tidy edges with minimal slag, reducing post-processing work. Building firms rely on it for cutting structural beam of lights, pipes, and steel sheets. The high-frequency plasma arc delivers regular outcomes even on unequal surfaces.

Musicians and metal designers use the CUT-200CNC for creating decorative items, signage, and sculptures. The CNC system enables specific control over complicated shapes and patterns. Users input develops by means of software, and the device executes cuts accurately. Upkeep teams in sectors such as shipbuilding and machinery fixing gain from its mobility and versatility. It reduces damaged steel parts for fast replacements.

The 380V power supply makes sure stable procedure under hefty workloads. The maker includes safety and security functions like overload protection and automatic voltage adjustment. Operators conserve time with its rapid setup and instinctive interface. Normal maintenance is straightforward, needing just fundamental cleaning and component checks.

Organizations minimize product waste due to the device’s effective nesting abilities. It takes full advantage of metal sheet usage, reducing manufacturing costs. The rugged build withstands extreme workshop settings. Educating brand-new operators takes minimal time many thanks to uncomplicated controls.

Industries needing high-volume result pick this equipment for its toughness and rate. It deals with recurring tasks without performance loss. Personalized setups let customers change reducing speed and power based on product density. The lack of consumables like gas cylinders simplifies operation.

The CUT-200CNC 380V satisfies international safety and high quality standards. Its compatibility with CAD/CAM software application streamlines process assimilation. Customers experience less errors with real-time tracking and mistake signals.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V

(CNC high frequency industrial plasma cut machine cutting machine CUT-200CNC 380V)

REQUEST A QUOTE

RELATED PRODUCTS

Hot ing Scr Thyristor Module IP147-3176 3500A2500V high frequency for furnace rectifier diode power controller whole

new original high frequency authentic high power thyristor SCR module KK600A1800V KK600-18 KK600A/1800V

new original high frequency authentic high power thyristor SCR module KP700A1600V KP700A/1600V KP700-16

Power Module High Frequency Rectifier SCR 323A3376P44 Phase Control Thyristor module

new original high frequency authentic high power thyristor SCR module KK2500A2500V KK2500A/2500V KK2500-25