Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

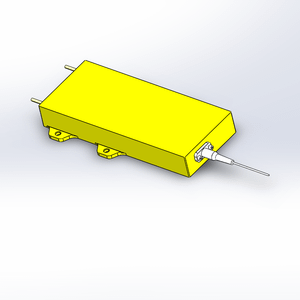

(W-70 heat sink heatsink for Single Phase Solid State Relay)

Specifications of W-70 heat sink heatsink for Single Phase Solid State Relay

The W-70 heat sink is created for usage with single-phase solid state relays to take care of warmth accumulation and make sure steady efficiency. It is made from aluminum alloy, which supplies strong heat dissipation and longevity. The material resists deterioration and deals with heats without deforming. The heat sink’s measurements are 150mm in size, 75mm in size, and 40mm in height. It considers 320 grams, making it lightweight for easy installment. The small size suits tight areas while preserving efficiency.

The thermal resistance rating is 0.45 ° C/W, allowing it to move warm far from the relay quickly. This quits getting too hot and expands the relay’s life-span. The style includes multiple fins to raise area, boosting air flow and air conditioning. The base plate is flat and smooth, making certain complete contact with the relay for optimum warmth transfer. Pre-drilled installing holes streamline setup. These holes match conventional relay dimensions, reducing the demand for added adapters.

Mounting equipment is included, such as screws and braces. The heat sink works with relays rated as much as 70A, making it optimal for industrial applications. It handles continuous procedure without shedding performance. The anodized surface area coating enhances warmth radiation and safeguards versus scratches. The black finish likewise blends with most devices configurations.

Operating temperature level varieties from -40 ° C to 150 ° C, appropriate for harsh settings. The W-70 fulfills RoHS and REACH criteria, ensuring safety and security and environmental conformity. Its straightforward design needs no maintenance. Customers can install it up and down or horizontally, depending on space and air flow demands. The warmth sink works with most single-phase relay brands, supplying versatility.

Examining shows the W-70 reduces relay temperatures by up to 35% under full lots. This avoids thermal shutdowns and keeps consistent power output. The mix of lightweight building and construction and high thermal performance makes it a useful choice for automation systems, motor controls, and power circulation devices.

(W-70 heat sink heatsink for Single Phase Solid State Relay)

Applications of W-70 heat sink heatsink for Single Phase Solid State Relay

The W-70 heat sink is made for use with single-phase solid-state relays. It takes care of warmth produced during procedure to maintain elements secure. Solid-state relays manage high-power devices in commercial settings. They create warm when switching over currents. Without proper air conditioning, this warmth can harm relay components or lower efficiency. The W-70 addresses this by moving heat away quickly.

The warmth sink works in motor control systems. Motors in factories or machinery compete long periods. This produces continuous heat. The W-70’s light weight aluminum building spreads warm evenly. Its fin style increases surface for faster air conditioning. This avoids overheating in relays attached to electric motors.

Power circulation systems additionally make use of the W-70. These systems manage high voltages. Relays switch over power between circuits. Warm develops during changing. The heat sink maintains temperatures low. This avoids abrupt failures in power networks. Plants and information centers depend on stable power. The W-70 helps in reducing downtime dangers.

Renewable resource setups benefit from this warm sink. Solar inverters and wind generator controls use solid-state relays. Exterior conditions include stress to elements. The W-70’s tough style takes care of weather condition adjustments. It keeps cooling down also in dirty or moist locations. This extends the life of relays in solar farms or wind parks.

The W-70 fits small rooms. Lots of commercial panels have actually limited room. The heat sink’s form allows very easy installation near relays. It collaborates with conventional installing hardware. Upkeep groups conserve time throughout arrangement or substitutes.

Automated production lines require trustworthy temperature level control. Robot arms or conveyor belts rely on solid-state relays. The W-70 makes sure these relays operate without disruptions. Less warmth suggests fewer errors in producing processes. Manufacturing facilities prevent pricey stops briefly from overheated tools.

Furnace in buildings use single-phase relays for a/c systems. The W-70 protects against overheating in limited electrical cabinets. Regular air conditioning enhances safety. It also reduces energy expenses by decreasing thrown away heat.

The warm sink supports high-current applications. Its layout takes care of sudden power rises. This is critical for hefty equipment or emergency situation systems. The W-70 maintains relays functioning under stress and anxiety. Equipment lasts much longer with consistent warm administration.

Compatibility with different relay versions makes the W-70 widely useful. It adjusts to various voltage and existing needs. Industries like automobile, telecommunications, and food processing utilize it for effective thermal control. Correct warm dissipation makes certain tools fulfill security standards.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality W-70 heat sink heatsink for Single Phase Solid State Relay, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of W-70 heat sink heatsink for Single Phase Solid State Relay

The W-70 heat sink is designed for Single Phase Solid State Relays. Here are answers to common questions.

What is the purpose of the W-70 heat sink?

The W-70 absorbs excess heat from the relay. Solid-state relays generate heat during operation. Without a heat sink, overheating can damage the relay. The W-70 prevents this by spreading heat away efficiently.

How do I install the W-70 on a relay?

Place the relay flat against the heat sink’s surface. Use thermal paste between them. Secure the relay with screws or mounting hardware. Ensure full contact between the relay and heat sink. Check tightness after installation.

Can the W-70 work with relays from other brands?

Yes. The W-70 fits most standard single-phase relays. Confirm the relay’s dimensions match the heat sink’s specs. Compatibility depends on size and mounting style. Check product details before purchasing.

Does the W-70 require maintenance?

Clean the heat sink regularly. Dust or debris reduces cooling efficiency. Inspect for damage or corrosion. Reapply thermal paste if the relay is reinstalled. No complex upkeep is needed.

What conditions affect the W-70’s performance?

High ambient temperatures reduce cooling capacity. Ensure proper airflow around the heat sink. Avoid blocking vents or fans. The relay’s load level also impacts heat output. Size the heat sink based on the relay’s maximum current.

Is a heat sink necessary for low-current applications?

Low-current relays produce less heat. A heat sink may still help. It extends the relay’s lifespan by stabilizing temperatures. Check the relay’s specifications for guidance. Use the W-70 if unsure.

(W-70 heat sink heatsink for Single Phase Solid State Relay)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Anodizing Extruded Aluminium Heatsink Extrusion Profile Aluminum Cooler Heat Sink

CoolCox GPU Cooler VC-AL4009 12V heatsink 41x40x9.8mm Vga Cooler Fan Generator Radiator Fan Graphics Card Fan

Customized Aluminium heatsink 6063 T5 Customized Aluminium Profile heatsink For Radiator Cooling System

Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion

High Power Inverter Power Supply Heat Sink Custom Aluminum Skiving Dense Thin Fins heatsink