Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

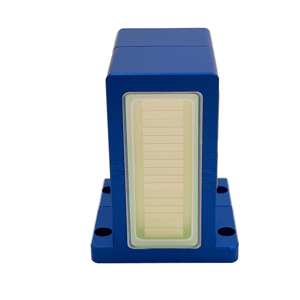

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry)

Specifications of High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

The High Warmth Dissipation Personalized Brass/Copper Heatsink is crafted for premium thermal monitoring in high-performance computing systems. Designed particularly for the computer system industry, this heatsink addresses the demanding air conditioning demands of CPUs, GPUs, power electronics, and web server parts. Its key function is to successfully transfer and dissipate heat produced by high-TDP (thermal layout power) equipment, making certain optimum performance and long life of delicate electronics.

** Material Specs **: The heatsink is crafted from premium-grade brass or copper, picked for their remarkable thermal conductivity. Copper boasts a thermal conductivity of 385 W/m · K, while brass offers 109 W/m · K, incorporated with improved resilience. These materials make certain fast warmth absorption and distribution, outshining standard aluminum heatsinks. The device is adjustable in dimensions, fin thickness, and base thickness to fit one-of-a-kind kind variables, including compact SFF (tiny kind factor) develops or massive web server racks.

** Style Includes **: Adjustable fin selections optimize area for passive or energetic (fan-assisted) air conditioning. Alternatives consist of marked, skived, or CNC-machined fins for accuracy airflow control. Surface therapies like nickel plating (3– 5 µm thickness) improve rust resistance and appearances. Placing compatibility covers mainstream sockets (LGA 1700, AM5) and personalized formats, with pre-drilled holes for protected setup. Thermal interface materials (TIM) such as firm copper bases or graphite pads ensure marginal thermal resistance (

(High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry)

Applications of High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

High heat dissipation heatsinks customized from brass and copper are crucial elements in the computer market, where effective thermal monitoring ensures optimum performance and long life of electronic tools. These materials are picked for their remarkable thermal conductivity, with copper offering exceptional heat transfer (about 385 W/m · K )and brass offering an affordable yet resilient option (109– 168 W/m · K). Personalized designs accommodate certain applications, such as cooling high-performance CPUs, GPUs, VRMs, and power components in desktops, web servers, gaming gears, and information facilities.

Brass and copper heatsinks are engineered to deal with area constraints and thermal difficulties in compact or high-density systems. Modification consists of customized dimensions, fin density, base thickness, and installing configurations to make best use of surface for warm dissipation while fitting distinct chassis layouts. Advanced production methods like CNC machining, die-casting, or skiving make certain accuracy for intricate geometries, such as warm pipes or vapor chambers in hybrid cooling solutions.

In video gaming Computers and overclocked systems, these heatsinks prevent thermal throttling, making it possible for sustained height performance. For servers and data centers, they reduce downtime by keeping secure temperature levels in processors and storage drives. Copper’s anti-corrosion properties and brass’s mechanical stamina make them excellent for rough atmospheres or commercial computing arrangements. Furthermore, copper’s compatibility with liquid cooling systems enables integration right into crossbreed thermal services for next-gen AI hardware or high-TDP GPUs.

Custom-made brass/copper heatsinks also sustain power efficiency by reducing the need for aggressive follower rates, minimizing sound and power consumption. Their longevity makes sure long-lasting dependability, also under continuous thermal biking. Producers commonly apply nickel or anti-oxidation finishes to improve life-span and aesthetics.

By partnering with a specialized vendor, companies can access customized thermal remedies that meet industry standards like RoHS and REACH, guaranteeing security and ecological conformity. Whether for consumer electronic devices, business equipment, or emerging technology, tailored brass/copper heatsinks provide targeted cooling, enhancing tool efficiency and protecting against overheating-related failures. For projects requiring accuracy thermal monitoring, these heatsinks are a scalable, high-performance option.

Company Profile

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

1. **What makes brass and copper ideal materials for high-heat-dissipation heatsinks in computers?**

Brass and copper are highly thermally conductive metals, with copper offering approximately 385 W/m·K and brass around 109 W/m·K. This allows efficient heat transfer away from sensitive computer components like CPUs, GPUs, or VRMs. Copper excels in rapid heat absorption and dissipation, while brass provides a cost-effective alternative with decent thermal performance and enhanced durability. Both materials resist corrosion and withstand high temperatures, making them reliable for long-term use in demanding computing environments.

2. **How does customization improve the performance of a heatsink for specific computer applications?**

Customized heatsinks are tailored to fit unique component layouts, thermal loads, and spatial constraints. By optimizing fin density, base thickness, and overall geometry, heat dissipation is maximized for specific processors or systems. Custom designs also ensure compatibility with existing cooling solutions (e.g., fans or liquid cooling loops) and account for airflow patterns within the chassis, reducing thermal throttling risks and improving system stability during intensive tasks like gaming or rendering.

3. **Can brass/copper heatsinks outperform standard aluminum heatsinks?**

Yes. Copper’s thermal conductivity is nearly double that of aluminum (205 W/m·K), enabling faster heat transfer. Brass, while less conductive than copper, still outperforms aluminum in high-temperature environments due to its rigidity and resistance to deformation. Custom brass/copper heatsinks are ideal for overclocked systems, servers, or compact builds where heat accumulation risks damaging components.

4. **Are these heatsinks compatible with all computer hardware?**

Custom heatsinks are designed to match specific hardware dimensions, mounting hole patterns, and thermal interface requirements. Manufacturers work with clients to ensure compatibility with sockets (e.g., AM5, LGA 1700), GPU layouts, or niche components like SSDs and voltage regulators. Custom brackets or adhesive solutions can also be integrated for non-standard installations.

5. **How do I maintain a brass or copper heatsink for longevity?**

Regularly clean dust/debris from fins using compressed air to maintain airflow. Avoid abrasive cleaners; instead, use isopropyl alcohol to remove old thermal paste. Copper may develop a patina over time, but this doesn’t impact performance. For brass, occasional polishing can restore aesthetics. Ensure proper thermal paste application during installation to prevent air gaps and optimize heat transfer. These materials require minimal maintenance, often outlasting the components they cool.

(High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry)

REQUEST A QUOTE

RELATED PRODUCTS

High Performance Customized Copper Heat Pipe heat sink Tube CPU Skived Bonding Fin Copper Heat Pipe Heatsink

High-Performance Air Cooling Solution for NVMe/SATA M.2 SSDs – Premium Aluminum Heatsink with Silicone Thermal Pad for Optimal PC Performance

H-P CPU Standard Radiator Heatsink For DL360G10

150mm Round Cold Forging Splayed Pin Fin Heatsink Led 100W aluminium heatsink led

Aluminum Heatsink ultra-thin Raspberry Pi routing chip radiator electronic heatsink 30 x 40 x 5mm with thermal