Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

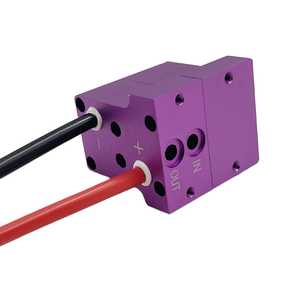

(fast sample delivery extruded aluminum heatsink)

Specifications of fast sample delivery extruded aluminum heatsink

This extruded light weight aluminum heatsink takes care of quick example shipment needs. It relocates warmth far from delicate parts successfully. The layout uses state-of-the-art light weight aluminum alloy. This product performs warmth extremely well. The alloy is lightweight yet solid.

The heatsink steps 100mm long, 60mm wide, and 30mm high. Its base is 5mm thick. This base makes good contact with the warmth source. Fins expand upwards from the base. These fins are 1.5 mm thick and spaced 5mm apart. This spacing maximizes the surface area exposed to air. Even more surface pulls even more heat away. The overall weight is 150 grams. This light weight protects against stress and anxiety on circuit boards.

Thermal resistance is low. It gauges 0.8 ° C/W. Lower resistance means much better air conditioning efficiency. The heatsink works with warmth loads up to 60 watts. This capability fits several requiring applications. Anodizing is the standard surface coating. This black finish improves warm radiation. It also shields versus rust. Various other surfaces are offered. You can request different shades or no anodizing.

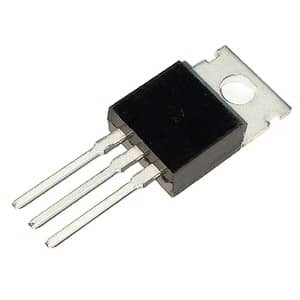

The extrusion procedure guarantees consistent high quality. Every item matches the requirements exactly. This heatsink fits usual cpu bundles. It deals with TO-220, TO-247, and similar gadgets. Mounting openings are pre-drilled. These openings approve conventional M3 screws. Thermal paste is advised for best contact. Use it in power supplies, motor drives, or LED lights. It cools amplifiers and various other electronics creating warmth.

(fast sample delivery extruded aluminum heatsink)

Applications of fast sample delivery extruded aluminum heatsink

Rapid sample delivery extruded light weight aluminum heatsinks are critical for cooling down electronic devices. They move heat far from hot components fast. This stops overheating. Overheating problems parts. It creates failings. Light weight aluminum is best for this job. It moves heat well. It is lightweight. It sets you back much less than copper. Extrusion forms the light weight aluminum. The metal obtains pushed with a mold and mildew. This produces complicated shapes quickly. These shapes have lots of area. More area cools much better. Air flows over the fins. Heat runs away into the air.

These heatsinks are utilized everywhere. Computer systems require them. Processors obtain very warm. Graphics cards require strong air conditioning. LED lighting utilizes them. Bright LEDs develop warmth. Heatsinks keep them bright longer. Power supplies produce heat. Heatsinks secure them. Industrial equipments make use of big heatsinks. Motors and drives need air conditioning. Electric cars rely on heatsinks. Batteries and electric motors have to remain trendy. Solar power systems require them. Power converters fume. Telecom devices uses them. Servers and routers require consistent cooling.

Fast sample distribution is crucial. Designers check layouts promptly. They obtain actual components quick. They examine the fit. They determine the cooling. They make modifications if needed. This speeds up advancement. Projects finish sooner. Products reach market faster. Getting examples quick avoids delays. Waiting weeks misbehaves. Quick examinations suggest better designs. The end product functions well. It lasts longer. It is extra reputable. Extruded aluminum provides adaptability. Several sizes and fin patterns exist. Custom forms are possible. This fits specific requirements. It fixes complicated air conditioning issues. Easy air conditioning typically uses these heatsinks. No followers are required. This conserves power. It reduces sound. It decreases expenses. Energetic cooling uses them also. Followers blow air over the fins. This cools down even hotter parts. Aluminum handles both techniques well. It is strong. It resists rust. It is easy to mount. Installing is simple. Thermal paste improves get in touch with. Warm transfers much better. This maintains temperature levels risk-free. Electronic devices run successfully. Performance stays high. Downtime is minimized. Maintenance is simpler.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality fast sample delivery extruded aluminum heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of fast sample delivery extruded aluminum heatsink

Fast Sample Delivery Extruded Aluminum Heatsink FAQs

1. How fast can you deliver samples?

We deliver samples very fast. Our standard turnaround is 1-2 weeks. We prioritize sample requests. We have dedicated production slots for them. This speed helps you test designs quickly.

2. Is the sample quality the same as production?

Yes, the sample quality matches production exactly. We use the same high-grade aluminum alloy. We use the same precision extrusion presses. We use the same surface finishing processes. Your sample shows the real product quality.

3. Can I get a custom design sample fast?

Yes, we make custom sample heatsinks quickly. We adjust our extrusion dies fast. We handle custom profiles efficiently. We don’t charge extra for custom samples usually. We confirm feasibility first.

4. Why are sample costs sometimes higher per unit?

Samples cost more per piece sometimes. Setup costs are the same for one piece or thousands. Extrusion requires die setup and machine calibration. We absorb some cost. Samples are often free or low-cost to help your project.

5. Are samples reliable for thermal testing?

Yes, samples are perfect for thermal testing. They are made from production material. They use the exact production process. Test results predict bulk order performance accurately. Engineers trust our samples for valid data.

(fast sample delivery extruded aluminum heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

Vram CPU GPU Cooling Chipset Heatsink Laptop M.2 SSD Thermal Silicone Conductive Interface Pad

Guangdong factory Cheap and good quality aluminum extruded heatsinks sold directly

Reasonable custom aluminum cnc machining anodized aluminum profile heatsink manufacture

Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink

Aluminum Heatsink ultra-thin Raspberry Pi routing chip radiator electronic heatsink 30 x 40 x 5mm with thermal