Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

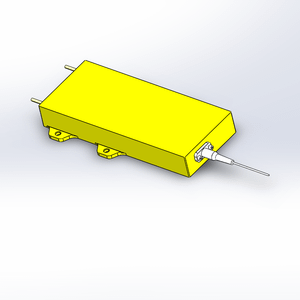

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(fast sample delivery extruded aluminum heatsink)

Specifications of fast sample delivery extruded aluminum heatsink

This extruded light weight aluminum heatsink relocates warm away fast. It maintains electronics cooler. Good thermal efficiency is important. We utilize top-quality light weight aluminum alloy 6063-T5. This material relocates warmth well. It is lightweight also. The extrusion process develops accurate, intricate forms. These shapes take full advantage of area. Even more surface area implies better cooling. You obtain efficient heat dissipation.

The heatsink comes in standard dimensions. Typical heights are 10mm, 20mm, 30mm. Lengths typically vary from 50mm to 300mm. Base densities vary. Standard is 3mm, 4mm, 5mm. We offer numerous fin thickness. Fin density impacts air movement and cooling down power. Choose the right density for your application. Personalized dimensions are feasible. Simply ask.

Surface area surface alternatives are offered. Natural mill finish is typical. It looks tidy and useful. Anodized finishes add shade. Black anodizing is popular. Plating likewise enhances deterioration resistance. It somewhat assists warm dissipation as well. Some layouts include installing holes. Others require different clips or adhesive. Inform us your placing needs.

Thermal resistance is reduced. This gauges exactly how well the heatsink transfers warmth. Reduced numbers are better. Our styles attain effective thermal monitoring. Weight is maintained marginal. Aluminum is naturally light. This stays clear of emphasizing motherboard. The style is durable. It handles typical handling and procedure.

We give fast example delivery. Get physical examples swiftly. Evaluate the heatsink in your real tool. Verify fit and cooling performance. Validate it fulfills your demands. This accelerates your advancement cycle. Avoid delays later. Demand examples easily. Our team focuses on quickly turnaround. See the top quality firsthand. Make decisions much faster.

(fast sample delivery extruded aluminum heatsink)

Applications of fast sample delivery extruded aluminum heatsink

Fast example shipment extruded light weight aluminum heatsinks solve prompt cooling demands. You obtain customized heatsink profiles swiftly. This rate is vital across many sectors requiring thermal control now.

Electronics count greatly on these heatsinks. Computers utilize them to cool down cpus and graphics cards. They prevent overheating inside tight spaces. Web servers require them to take care of warm from numerous chips running frequently. Power supplies make use of extruded light weight aluminum to stay amazing under hefty electrical tons. They just function successfully.

LED lights demands great warmth administration. Bright LEDs create considerable warmth. Extruded aluminum heatsinks mount directly to LED boards. They pull warm away quickly. This keeps lights intense longer. It avoids early failure. Road lights, indoor fixtures, and stage lights all rely on this cooling approach.

Power electronics need robust air conditioning remedies. Solar inverters transform power and get hot. Motor drives control huge motors and need warmth dissipation. Rapid shipment extruded heatsinks fit these power systems flawlessly. They deal with high temperatures reliably. This secures delicate electronic components nearby.

Electric automobiles make use of these heatsinks thoroughly. Battery packs demand temperature level law for security and performance. Onboard chargers and power controllers produce heat. Extruded light weight aluminum cools down these critical EV systems efficiently. Its light-weight nature is a major benefit here.

Industrial automation benefits as well. Motor controllers, servo drives, and PLCs produce heat in control cupboards. Extruded heatsinks install straight to hot parts. They keep steady operating temperature levels on factory floors. This lowers maker downtime dramatically.

Manufacturing equipment itself makes use of extruded aluminum for cooling. Laser cutters, 3D printers, and CNC devices have hot spots. Quick sample heatsinks offer instant thermal relief during prototyping and manufacturing ramp-up. They make it possible for quicker item development cycles.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality fast sample delivery extruded aluminum heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of fast sample delivery extruded aluminum heatsink

(fast sample delivery extruded aluminum heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

Silver Tone Aluminium Radiator Heatsink Cooling Fins Cooler Heat Sink for Led Amplifier Transistor IC Module

Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

QiuzAim desk 4-Heatpipes 120mm RGB Heatsink Radiator Tower For Computer AM5 Server Dual X99 Motherboard PC Cooling Performance

China OEM Custom Perfil De Aluminio Extruded Support Holder Heatsink Extrusion Aluminum Profile for Led Strip Light

mw-i-50 heatsink Aluminum radiator for 10A 25A 40A single phase ssr