Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

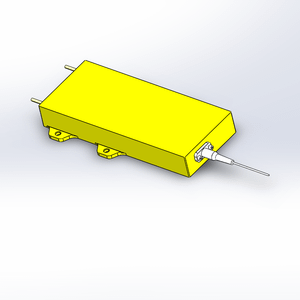

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink)

Specifications of Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink

The Personalized Extruded Light Weight Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink deals with high-performance warmth control. It mixes extruded light weight aluminum, copper warm pipes, and a vapor chamber to eliminate warmth quickly. The extruded light weight aluminum base provides a large area. This spreads out heat better. Copper warmth pipelines pull warmth from hot spots to the fins. The vapor chamber levels warm throughout the whole device. This configuration relocates warmth away quickly.

The light weight aluminum body is light and solid. It does not corrosion and operates in hot problems. Copper parts move warm well. They move heat away from important areas. The vapor chamber quits irregular home heating. This maintains temperatures steady even in tough arrangements.

You can change dimensions, forms, and fin formats. This makes the heatsink fit different devices and heat demands. It fits in little areas. It takes care of effective devices without occupying additional area.

This heatsink operates in computer systems, LED lights, automobiles, and manufacturing facility devices. It cools down CPUs, GPUs, power components, and motor drives. It quits gadgets from obtaining as well warm. This helps them last longer and work much better.

The item stays reputable under heavy usage. It works the very same in severe warmth or cold. All materials pass top quality checks. They match industry policies. It saves money by cutting the requirement for additional air conditioning components.

The extrusion technique lets shapes match certain needs. Copper pipelines and the vapor chamber collaborate to move warmth best. This combo boosts cooling down power. Each device gets examined difficult to make sure it functions appropriate each time.

(Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink)

Applications of Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink

Personalized squeezed out aluminum heat sinks integrated with copper warmth pipes and vapor chamber innovation deal dependable thermal administration services for high-performance systems. These elements work together to relocate warm far from sensitive parts, making certain steady procedure popular atmospheres.

Electronics like computers and web servers utilize these heatsinks to cool CPUs and GPUs. The light weight aluminum base takes in warmth, while copper pipes transfer it swiftly to fins. Vapor chambers spread out warmth equally, preventing hot spots. This configuration sustains heavy workloads in data centers and gaming rigs.

Electric cars count on these heatsinks for battery packs and power converters. Efficient cooling extends battery life and avoids overheating throughout quick charging. Light weight aluminum’s light-weight residential or commercial properties help reduce car weight, boosting energy performance.

High-power LED lighting systems make use of these solutions to manage warm in streetlights and commercial components. Constant cooling maintains illumination and lengthens LED life expectancy. The style enables compact installments without compromising performance.

Industrial machinery like motor drives and power materials benefit from resilient thermal administration. Extruded light weight aluminum deals with severe problems, while copper pipes and vapor chambers preserve stable temperatures during continual procedure. This decreases downtime and upkeep costs.

Telecommunications tools such as 5G base stations needs reliable warmth dissipation for signal processors and transceivers. These heatsinks make sure stable connectivity in high-traffic networks. Their modular layouts adapt to tight areas in towers and routers.

Renewable energy systems like solar inverters and wind turbines use these parts to cool down power electronic devices. Reputable warm management boosts power conversion performance and system durability, also in extreme climate.

Aerospace applications consist of avionics and satellite systems. The mix of materials withstands vibration and temperature level changes while maintaining crucial tools within risk-free operating varieties.

Medical devices like imaging machines and surgical tools depend upon exact cooling to stay clear of breakdowns. These heatsinks provide silent, regular performance in delicate health care atmospheres.

Consumer electronics such as video gaming consoles and laptops use small variations of these solutions. They make it possible for thinner layouts without overheating throughout prolonged usage.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink

What is a custom extruded aluminum heat sink with copper heatpipes and vapor chamber?

This product combines extruded aluminum for basic heat spreading, copper heatpipes for fast heat movement, and a vapor chamber for even heat distribution. These parts work together to cool high-power electronics efficiently. The aluminum structure is lightweight and cost-effective, while copper and vapor chamber parts handle intense heat spots.

Why pick this type of heatsink over standard options?

Standard heatsinks often use one material or method. This hybrid design improves cooling by merging different technologies. Extruded aluminum offers a large surface area for heat release. Copper heatpipes move heat quickly from hotspots to cooler zones. The vapor chamber spreads heat evenly across the surface. This mix handles higher heat loads better than basic designs.

Where are these heatsinks typically used?

They work in devices needing strong cooling without heavy parts. Common uses include computer CPUs, LED lighting systems, power converters, and industrial machinery. Electronics that run hot for long periods or need quiet operation often use these heatsinks.

How are custom designs created?

Manufacturers adjust the size, shape, and layout based on the device’s heat output, space limits, and airflow conditions. They might change the number of heatpipes, vapor chamber size, or aluminum fin density. Custom mounting holes, surface coatings, or finishes can also be added.

What affects the heatsink’s performance?

Key factors include the heat source’s power, contact between the heatsink and the component, airflow speed, and ambient temperature. Proper installation ensures the heatsink sits flat against the heat source. Using thermal paste or pads fills tiny gaps for better heat transfer. Dust buildup or blocked airflow reduces efficiency over time.

(Custom Extruded Aluminum Heat Sink Copper Heatpipe Vapor Chamber Heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile

High Performance And Compact Heatsinks Cooling Heat Sink Radiato Heat Sink Custom Anodized Aluminium Heat Sink

TCH Factory High Quality heatsinks Custom heatsink Aluminum Profile Extrusion Service Heat Sink

Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks