Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

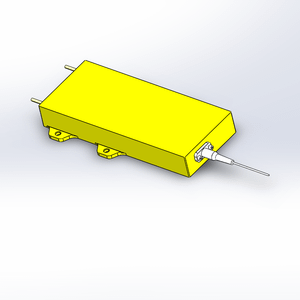

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion)

Specifications of Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion

This light weight aluminum heatsink profile is created for commercial applications requiring high efficiency and long-lasting integrity. Developed with custom-grade light weight aluminum alloy, it offers exceptional toughness and longevity. The product undergoes a conventional extrusion procedure, guaranteeing accurate measurements and constant top quality. Each account is anodized to improve surface area hardness and resistance to deterioration, scrapes, and put on. This makes it suitable for rough atmospheres or durable procedures.

The design focuses on effective thermal administration. The structure includes enhanced fins and grooves to optimize heat dissipation. This aids maintain steady temperatures in electronic parts, machinery, or power systems. Personalization choices are offered to meet certain project demands. Changes can be made to the account’s length, density, and form. This versatility makes certain compatibility with different tools layouts or area constraints.

High-strength aluminum alloy gives a robust base while keeping the product light-weight. This equilibrium reduces overall system weight without endangering structural integrity. The plated layer includes added security versus chemical direct exposure or weather-related damages. It likewise improves appearances by offering an attire, matte finish.

Standard extrusion allows economical production while preserving tight tolerances. Complicated cross-sectional designs are possible to boost capability. Pre-drilled openings or mounting slots can be integrated for simple installment. This lessens setting up time and labor expenses.

Compatibility with common commercial elements makes sure smooth combination. The profiles collaborate with conventional bolts, braces, and cooling down systems. This streamlines upgrades or repairs in existing arrangements.

Longevity testing verifies the product’s ability to stand up to repeated thermal cycles and mechanical stress and anxiety. It carries out reliably in high-temperature atmospheres or continuous operation circumstances. Minimal upkeep is needed due to the corrosion-resistant coating.

The light weight aluminum heatsink account is ideal for industries like automation, renewable resource, automotive, and telecommunications. Its adaptability suits both small models and large-volume manufacturing runs. Custom-made orders include technical assistance for layout optimization and efficiency recognition.

Product buildings adhere to international requirements for safety and security and ecological effect. Recyclable light weight aluminum supports sustainable manufacturing practices. Manufacturing preparation continue to be short even for specialized setups. Mass orders receive affordable rates to enhance project cost performance.

(Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion)

Applications of Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion

Aluminum heatsink profiles are commonly made use of in industrial settings. They take care of warm in electronic devices, equipment, and high-power systems. These accounts are tailor-made to fit specific demands. Industries like electronics, auto, LED lights, and renewable energy count on them.

The accounts are constructed for high toughness. They manage hefty loads and resist deformation under anxiety. This sturdiness comes from innovative extrusion techniques. The process shapes light weight aluminum right into exact layouts. Criterion extrusion guarantees consistent high quality. It allows automation without losing performance.

Plating is a key feature. It adds a safety layer to the aluminum. This layer protects against deterioration and wear. It enhances warmth dissipation. Anodized surfaces likewise look cleaner. They stand up to scrapes and chemical damage. This makes the heatsinks last much longer in rough settings.

In electronic devices, heatsinks cool components like CPUs and GPUs. They prevent overheating in web servers and power products. Personalized shapes fit tight spaces. They make best use of cooling effectiveness. Automotive systems make use of these accounts in electrical vehicles. They cool battery packs and electric motor controllers. Effective warmth administration extends automobile life expectancy.

LED lights requires dependable cooling. Aluminum heatsinks maintain secure temperatures. They prevent light degeneration and part failure. This makes sure regular brightness. Renewable energy systems like photovoltaic panels use heatsinks also. They protect inverters and power converters from warmth damage. This boosts energy efficiency.

Industrial machinery creates warmth throughout operation. Heatsinks avoid equipment shutdowns. They reduce maintenance prices. Custom-made creates adapt to one-of-a-kind device formats. This versatility sustains varied applications.

The combination of strength, sturdiness, and personalization makes light weight aluminum heatsink profiles vital. They fulfill strict market requirements. Their light-weight nature saves power in transportation and installment. Plating and extrusion procedures guarantee they execute reliably gradually.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion

What is an aluminum heatsink profile?

Aluminum heatsink profiles are metal components used to manage heat in industrial equipment. They absorb and disperse heat from electronic parts. This prevents overheating. The profiles are made from aluminum. Aluminum is lightweight. It conducts heat well.

Can the heatsink profiles be customized?

Yes. These heatsinks can be tailored to fit specific needs. Custom shapes and sizes are possible. Modifications include adjusting dimensions, adding grooves, or altering fin designs. Industries provide requirements. Manufacturers then produce profiles matching those needs.

Why choose anodized aluminum heatsinks?

Anodizing adds a protective layer to the aluminum. This layer resists corrosion. It improves durability. Anodized surfaces handle harsh environments better. They last longer. The process also allows color options. This helps with branding or part identification.

Are these heatsinks strong enough for heavy-duty use?

Yes. The aluminum used is high-strength alloy. It maintains structural integrity under stress. Extrusion methods ensure consistent quality. These heatsinks support heavy industrial applications. They manage heat without warping or degrading.

What are standard extrusion advantages?

Standard extrusion uses pre-designed molds. This reduces production time. It cuts costs. Standard shapes are readily available. They suit common industrial needs. Custom extrusions are still possible. But standard options offer faster delivery and lower prices.

(Aluminum Heatsink Profile For Industry Custom High Strength Durable Anodized With Standard Extrusion)

REQUEST A QUOTE

RELATED PRODUCTS

High Performance Customized Copper Heat Pipe heat sink Tube CPU Skived Bonding Fin Copper Heat Pipe Heatsink

Square Extruded Aluminum Heatsink with Fan for Computer CPU

High Quality Machining Radiator Cooling Heatsink Aluminum Transformer Heat Sink Piece

Customized Heatsink For Leds Extruded Aluminum Heat Sink

80/90/120/240/280mm water cooling radiator cooler for computer CPU industrial Laser Heat Exchanger heatsink