Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

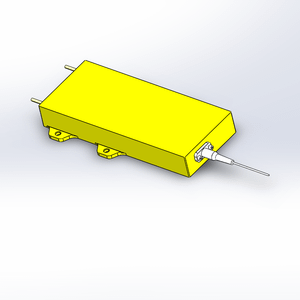

(Aluminium housing heatsink customized for industry parts extruded heatsink factory)

Specifications of Aluminium housing heatsink customized for industry parts extruded heatsink factory

Our factory makes custom-made light weight aluminum heatsinks for industrial tools parts. You need a heatsink fitting your specific part. We make that occur. Light weight aluminum extrusion creates these heatsinks. This procedure shapes heated light weight aluminum with a die. It creates complex, long accounts efficiently. This approach gives excellent thermal efficiency. Light weight aluminum relocates heat fast far from warm parts. Your equipment remains cooler. Cooler tools runs far better and lasts much longer.

Personalization is crucial. We create the heatsink shape around your certain component. The heatsink needs to call the warmth source flawlessly. Good call implies reliable warmth transfer. We accomplish exact fits. Tell us your demands. We design the account accordingly. Consider room limits, air movement, mounting points, and warm tons. Our designers deal with your information. They create the ideal form.

We utilize top-quality aluminum alloys. These alloys perform warmth efficiently. They are also strong and lightweight. Aluminum resists deterioration well. It holds up in tough commercial settings. The extrusion process enables complex fin designs. Even more area suggests better cooling. Air conforms the fins quickly. Warm dissipates promptly right into the surroundings.

Our factory regulates the entire procedure. We style, extrude, reduce, maker, and surface heatsinks here. Machining creates specific installing surface areas or openings. We make certain smooth call locations. Surface coatings like plating are choices. Anodizing boosts appearances and deterioration resistance. We provide heatsinks ready for setting up. They set up straight onto your parts. This fixes your overheating problems efficiently. We support varied markets needing dependable thermal monitoring.

(Aluminium housing heatsink customized for industry parts extruded heatsink factory)

Applications of Aluminium housing heatsink customized for industry parts extruded heatsink factory

Light weight aluminum housing heatsinks address heat problems in several commercial parts. Manufacturing facilities build these heatsinks making use of extrusion. Extrusion pushes warm aluminum through a designed opening. This process produces long, accurate heat-dissipating accounts. Customizing these profiles is vital for various sector needs.

Electronic devices need small heatsinks. Extruded aluminum forms fit securely around motherboard. Automotive parts generate lots of warm. Custom extruded heatsinks manage engine control device temperatures. Power materials and motor drives call for robust cooling. Thick aluminum fins pull warmth away successfully.

Factories customize heatsinks for specific jobs. They change the fin design. Even more fins mean more surface area. Better area suggests faster cooling. They alter the base thickness. A thicker base soaks up warm quicker. They choose various light weight aluminum alloys. Some alloys perform warm much better. Others offer more stamina. Surface area finishes matter as well. Plating safeguards against corrosion. It likewise helps heat retreat.

Custom extrusion supplies big benefits. It makes heatsinks fit certain tools flawlessly. Perfect fit makes sure the very best warm transfer. Extrusion permits complex shapes. Complex shapes cool challenging areas properly. Aluminum is light. Light heatsinks don’t include much weight. Aluminum resists rust well. This is vital in difficult factory or exterior setups.

Manufacturing facilities collaborate with designers. They transform design ideas into real extruded heatsinks. They make models first. Examining confirms the style functions. Then complete production beginnings. Quick turn-around times prevail. This heatsink option cools down crucial industrial elements reliably.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Aluminium housing heatsink customized for industry parts extruded heatsink factory, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Aluminium housing heatsink customized for industry parts extruded heatsink factory

Here are 5 common questions about our custom aluminum housing heatsinks for industrial parts:

Can you make heatsinks for my specific industrial equipment? Yes. We specialize in custom extrusion. You tell us your exact requirements: the machine part type, thermal load, space limits, mounting method, and environment. We design and manufacture the heatsink to fit perfectly and cool effectively. Many unique industrial parts need this solution.

What aluminum alloys do you use? Primarily 6063 and 6061. These alloys offer excellent thermal conductivity. They are strong enough for most industrial settings. We choose the best alloy for your application’s heat dissipation needs and mechanical strength requirements. Sometimes we use other alloys if needed.

How much does custom extrusion cost? Cost depends on several factors. These include the heatsink’s size, complexity, chosen alloy, surface finish, and order quantity. Simple designs in larger volumes cost less per unit. Complex shapes or small batches cost more. We provide detailed quotes upfront based on your specifications. There are no hidden fees.

How long does production take? Lead time varies. Standard custom orders typically take 3 to 5 weeks. This includes design approval, tooling setup, extrusion, cutting, machining, and surface treatment. We give a firm timeline when you place your order. Rush services are sometimes possible for urgent needs. Ask us about this.

Do you apply surface finishes? Yes. We offer anodizing as standard. This protects the aluminum from corrosion. It improves durability in harsh industrial environments. It also gives a professional look. We can do clear or colored anodizing. Other finishes like powder coating are also available upon request.

(Aluminium housing heatsink customized for industry parts extruded heatsink factory)

REQUEST A QUOTE

RELATED PRODUCTS

With Adhesive Cooling and 6 Optional Three-piece Raspberry Pi 4 4B heat sink Heatsink Set

High Polished Custom Aluminum Large Copper extrusion heatsink customized heat sink sunflower heat sink for led

OEM Customized Aluminum Extruded Heatsink Custom Aluminum Heat Sink

Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

High Quality Custom OEM 50W LED Heatsink Anode Cold Forging Aluminum LED IP68 Heat Sink in Silver Factory Direct