Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

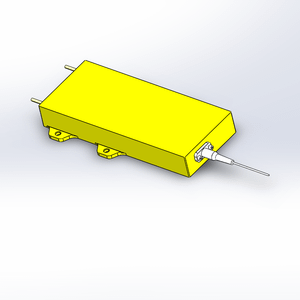

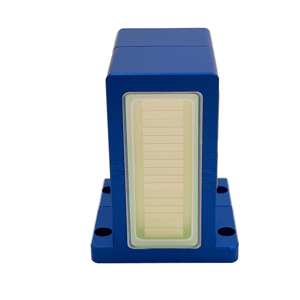

(6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile)

Specifications of 6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile

The 6061T6 and 6063T5 CNC hollow extruded heatsink extrusion is developed for commercial warmth management. It uses state-of-the-art light weight aluminum alloys for toughness and thermal performance. The 6061T6 alloy supplies outstanding mechanical properties. It resists corrosion and takes care of high-stress atmospheres. The 6063T5 alloy offers remarkable surface coating and formability. It is perfect for complex forms calling for precision. Both products make sure effective warm dissipation in demanding applications.

The hollow extrusion layout minimizes weight without sacrificing resilience. This boosts installation flexibility in tight spaces. CNC machining guarantees precise measurements and smooth edges. The procedure guarantees consistency throughout large manufacturing runs. Custom sizes and hole patterns are available. This permits assimilation with various components like circuit boards or equipment.

Thermal conductivity is a vital function. The 6061T6 alloy achieves 167 W/m · K. The 6063T5 alloy gets to 201 W/m · K. This difference fits various cooling down needs. Higher conductivity materials transfer warm much faster. Lower conductivity choices balance expense and performance. Both alloys work in temperature levels from -50 ° C to

175 ° C. Surface area therapies improve capability. Anodizing adds corrosion resistance and boosts looks. Powder layer supplies added protection versus extreme atmospheres. Neglected surfaces are likewise readily available for customized post-processing.

Applications include electronics cooling, auto systems, LED lights, and power materials. The design supports passive and active cooling configurations. Fins enhance surface area for better air flow. This takes full advantage of warmth exchange without outside power.

Standard profiles are ready for prompt use. Custom-made layouts can be produced with minimal lead time. Tolerances are limited, typically within ± 0.1 mm. This guarantees compatibility with industry-standard placing hardware.

The combination of CNC precision and extrusion technology develops reputable services. It satisfies requirements for sectors prioritizing thermal administration. Efficiency stays steady under continuous operation. Upkeep demands are low as a result of robust product residential properties.

Options for additional handling include boring, threading, or cutting. This versatility sustains quick prototyping and automation. Expense effectiveness is accomplished with product optimization and scalable manufacturing. The item matches both small tasks and large commercial systems.

(6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile)

Applications of 6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile

The 6061-T6 and 6063-T5 CNC hollow extruded heatsink extrusion warmth sink industrial aluminum accounts are commonly utilized in markets needing efficient thermal management. These aluminum accounts are used state-of-the-art alloys. The 6061-T6 offers high strength and rust resistance. The 6063-T5 offers superb thermal conductivity and surface area coating. Both materials are excellent for custom styles due to their adaptability to CNC machining.

These heatsinks prevail in electronic devices. They cool down components like CPUs, GPUs, and power modules. The hollow style enhances surface. This boosts heat dissipation. The lightweight nature of aluminum decreases general system weight. This is critical for portable gadgets and small systems.

In the automotive industry, these profiles manage warmth in electric lorries and charging systems. They take care of heats from batteries and power electronics. The deterioration resistance ensures toughness in extreme settings. CNC machining permits specific assimilation right into lorry designs.

Industrial machinery utilizes these heatsinks to cool down electric motors, drives, and control systems. Efficient air conditioning avoids overheating. This prolongs equipment life-span. The extruded forms match tight areas. Customized lengths and opening patterns streamline installment.

LED lights systems count on these profiles to keep optimal temperature levels. Proper warmth monitoring prevents light degeneration. It guarantees regular brightness and shade. The smooth surface of 6063-T5 permits simple anodizing. This enhances looks and longevity.

Renewable resource applications consist of solar inverters and wind turbine controllers. These systems generate considerable warmth during procedure. Aluminum heatsinks stabilize temperature levels. This ensures trusted efficiency in exterior problems.

Aerospace and protection markets make use of these accounts for avionics and radar systems. The mix of lightweight building and construction and thermal effectiveness satisfies rigorous market standards. CNC-machined features allow intricate geometries. This supports high-precision applications.

The hollow extrusion design lowers material use. It reduces prices without endangering efficiency. The flexibility of 6061-T6 and 6063-T5 alloys makes these heatsinks appropriate for diverse projects. They balance functionality, toughness, and cost-effectiveness.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile

What materials are used in 6061-T6 and 6063-T5 aluminum heatsinks? Both alloys are common in industrial applications. 6061-T6 offers higher strength and better machinability. It suits heavy-duty environments. 6063-T5 has smoother surfaces and better corrosion resistance. It works well for detailed designs. The choice depends on specific project needs.

How does the hollow design improve heat dissipation? Hollow sections reduce weight without sacrificing structural integrity. Air flows through the channels more efficiently. This increases surface area for heat transfer. The design prevents overheating in tight spaces. It balances performance and space-saving needs.

Can these heatsinks be customized for unique applications? Yes. CNC machining allows precise modifications. Holes, slots, or grooves can be added. Dimensions adjust to fit specific equipment. Custom shapes are possible. Manufacturers often provide tailored solutions based on technical drawings.

What industries use these aluminum heatsinks? Electronics and automotive sectors rely on them. LED lighting systems use them for thermal management. Power supplies and motor controllers benefit from their cooling efficiency. Renewable energy systems like solar inverters also apply them. Any high-heat environment might require these components.

How do 6061-T6 and 6063-T5 compare in cost? 6063-T5 is generally cheaper due to easier extrusion processes. 6061-T6 costs more but handles heavier loads. Budget and performance needs influence the decision. Large-scale projects might prefer 6063-T5 for cost savings. High-stress applications justify the higher price of 6061-T6.

What maintenance do these heatsinks require? Regular cleaning prevents dust buildup. Check for corrosion in harsh environments. Ensure mounting surfaces stay flat for optimal contact. Thermal paste might need reapplication over time. Proper airflow around the heatsink must be maintained.

(6061t6 6063t5 CNC Hollow Extruded Heatsink Extrusion Heat Sink Industrial Aluminum Profile)

REQUEST A QUOTE

RELATED PRODUCTS

Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

Factory customized aluminum heat sink PV inverter aluminium heatsink led discipador perfil de aluminio

Customizes Various Sizes Of Motherboard Chip Heat Sink Aluminum Cold Forging Raspberry Pi 4b heatsink

Factory Customized 800w CPU heatsink PC Aluminium Fin Heatpipe Heat Sinks Welding 3 Copper Heat Pipe For GPU Amplifier & Laser

whole high power heatpipe heatsink module