Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

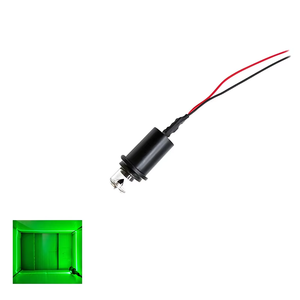

Overview of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

Diode modules are assemblies consisting of multiple diodes that are packaged together to form a single, easy-to-install unit. They are widely used in power electronics for rectification (converting AC to DC), protecting circuits from overvoltage and reverse current, and many other applications. Diode modules typically contain different types of diodes, such as fast recovery diodes, Schottky diodes, etc., to suit specific application requirements.

Features of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

High reliability: By integrating multiple diodes, the risk of single component failure is reduced.

Simplified design: Using modules can reduce PCB space requirements and simplify circuit design.

High efficiency: Some diode modules use advanced materials and technologies to provide lower forward voltage drop and higher efficiency.

Good heat dissipation: Many modules are designed with efficient heat dissipation paths to ensure stable operation under high power conditions.

Easy to install and maintain: Standardized packaging makes installation and replacement easier and faster.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

Specification of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

This Peltier component cools 808 laser diodes, laser heaps, thermoelectric cooler shells. It makes certain stable temperature level control for high-power laser systems. The air conditioning capability reaches 50W maximum. The operating voltage is 12V DC. The current draw is 6A under complete tons. The temperature distinction in between cold and hot sides can strike 70 ° C. The component determines 40mm x 40mm x 4mm. It fits most standard laser diode real estates. The chilly side get in touches with the laser diode directly. The warm side connects to a heatsink or cooling system. Thermal paste improves warm transfer effectiveness. The ceramic plates on both sides ensure electric insulation. Copper conductors inside increase thermal conductivity. The component functions in between -50 ° C and 150 ° C. It deals with high warmth loads without performance loss. The durable construction stands up to thermal tiredness. The solder-free design protects against leaks or corrosion. The bismuth telluride semiconductor material makes certain long-term reliability. Reverse polarity security is included. The component runs quietly. No relocating components mean minimal upkeep. Personalized voltage or size options are readily available. The chilly side temperature level stabilizes within secs. It matches commercial, clinical, or scientific laser applications. The component couple with temperature level sensors for automated control. Accurate thermal management prolongs laser diode life expectancy. The compact style saves space in tight arrangements. State-of-the-art materials stand up to continuous procedure. The flat surface makes sure also exposure to elements. Examining verifies 50,000 hours of solution life. Setup needs minimal tools. The module works with air or fluid air conditioning systems. Voltage spikes or rises do not harm interior components. Thermal biking tests verify security under extreme conditions. The product satisfies worldwide security and performance standards. Reliable heat dissipation stops laser wavelength drift. Efficient cooling preserves optimum diode performance. The module works with most driver circuits. Technical support is offered for assimilation inquiries. Mass orders include marked down rates.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

Applications of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

Peltier components play a vital function in taking care of temperature level for high-power laser systems like 808 laser diodes and laser stacks. These gadgets generate significant heat during procedure. Without correct air conditioning, performance drops and life-span reduces. Peltier thermoelectric coolers solve this by actively moving warm away from crucial elements. This guarantees secure temperature levels also under heavy workloads.

For 808 laser diodes, exact thermal control is essential. These diodes run popular atmospheres like clinical devices or commercial cutting devices. Peltier coolers readjust cooling down power dynamically based upon real-time warm output. This avoids getting too hot and preserves consistent laser result. The small dimension of Peltier components fits perfectly right into diode housings without adding mass.

Laser heaps incorporate several diodes to increase power. Warmth build-up boosts with each included diode. Standard air conditioning methods usually have a hard time to handle concentrated heat areas. Peltier-based systems offer targeted air conditioning by connecting directly to warm resources. This strategy improves efficiency and lowers power waste. It also minimizes temperature level variations that can damage sensitive optics.

The thermoelectric cooler covering incorporates Peltier modules into a protective real estate. This layout guards elements from dust, moisture, and physical damage. It additionally enhances warmth dissipation with optimized air movement paths. Users benefit from quieter operation compared to fan-driven systems. Upkeep needs reduction because Peltier units have no relocating parts.

Industrial applications depend on these components for constant procedure. Fiber laser cutting devices use them to maintain high-power results during lengthy changes. Clinical lasers depend on stable temperature levels for accurate surgical procedures. Telecom tools utilizes Peltier-cooled lasers to keep signal stability with time.

Energy efficiency is another benefit. Peltier colders eat much less power than compressor-based systems. They operate on direct existing, making them compatible with portable laser gadgets. Personalized sizes and shapes allow combination into specialized setups. This flexibility sustains both small models and mass-produced systems.

Longevity guarantees lasting integrity in severe conditions. Peltier modules hold up against resonances, temperature level extremes, and fast thermal biking. Customers prevent constant substitutes, reducing total expenses. Advanced products in the cooler covering stand up to rust and electrical disturbance.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

1. What does a Peltier module do for an 808 laser diode? The Peltier module controls the laser’s temperature. It moves heat away from the diode using electricity. This keeps the laser stable. Lasers work poorly if they get too hot. The module stops overheating.

2. Why is temperature control important for laser stacks? Laser stacks create lots of heat during operation. Uncontrolled heat reduces performance. It can damage parts. The Peltier cooler maintains a set temperature. This ensures longer life for the laser. It also keeps output power consistent.

3. How do I install the Peltier module with my laser? Clean the laser surface first. Apply thermal paste evenly. Place the module against the laser. Secure it with screws or clamps. Connect wires to the power supply. Test the cooling effect before full use. Wrong installation causes poor cooling.

4. Can this cooler work with different laser types? Yes. The module fits most 808nm diode lasers. Check the size and power requirements first. Match the cooler’s specs to the laser’s heat output. Some lasers need extra heat sinks. Contact the supplier for compatibility details.

5. What if the Peltier module fails to cool properly? Check the power supply. Ensure voltage matches the module’s rating. Inspect wiring for damage. Look for loose connections. Clean dust from the module surface. Replace worn thermal paste. If problems continue, the module might be faulty. Replace it with a new unit.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

REQUEST A QUOTE

RELATED PRODUCTS

IGTB power module thyristor diode 2MBI75VA-170-50

New original smd diode PMEG3010EH SOD-123 Support BOM Fast delivery

MPJC2CA100U40 (Fast recovery diode module) Original new in stock

CS-mounted 808nm Diode Laser Bars Pump Laser Module

NEW 500W 600W 800W 1000W 1200W laser stack for diode laser/ diode laser bar module / diode laser bars