Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

Diode modules are assemblies consisting of multiple diodes that are packaged together to form a single, easy-to-install unit. They are widely used in power electronics for rectification (converting AC to DC), protecting circuits from overvoltage and reverse current, and many other applications. Diode modules typically contain different types of diodes, such as fast recovery diodes, Schottky diodes, etc., to suit specific application requirements.

Features of DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

High reliability: By integrating multiple diodes, the risk of single component failure is reduced.

Simplified design: Using modules can reduce PCB space requirements and simplify circuit design.

High efficiency: Some diode modules use advanced materials and technologies to provide lower forward voltage drop and higher efficiency.

Good heat dissipation: Many modules are designed with efficient heat dissipation paths to ensure stable operation under high power conditions.

Easy to install and maintain: Standardized packaging makes installation and replacement easier and faster.

(DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K)

Specification of DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

The DD89N series diode rectifier modules cover models DD89N12K, DD89N14K, DD89N16K, and DD89N18K. These components take care of high-power correction tasks. They transform air conditioner to DC power efficiently. Each design shares an ordinary forward current score of 89 amperes. Their voltage capabilities vary. The DD89N12K supports 1200 volts reverse recurring height voltage. The DD89N14K handles 1400 volts. The DD89N16K takes care of 1600 volts. The DD89N18K withstands 1800 volts. This voltage ranking is vital for obstructing reverse current circulation.

All modules utilize a common industry plan style. This design guarantees compatibility with usual warm sinks. It promotes reliable thermal management. Reduced thermal resistance is a crucial function. Warmth dissipates rapidly during procedure. The modules tolerate high surge currents. This shields against unexpected power spikes. Electrical seclusion satisfies safety and security criteria. It prevents short circuits in high-voltage configurations.

These rectifiers run across a vast temperature range. They work from -40 degrees Celsius to 150 degrees Celsius. This makes them appropriate for harsh commercial environments. Typical applications consist of motor drives for manufacturing facility equipment. They power uninterruptible power supplies for back-up systems. Welding machines count on their constant performance. Commercial power products integrate them also. Renewable energy converters utilize these modules.

Durable building ensures long-lasting dependability. Quality products minimize failure threats. The components meet international sector criteria. Their style prioritizes resilience under hefty lots. Maintenance requirements are very little. Engineers trust them for essential power control tasks.

(DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K)

Applications of DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

The DD89N series diode rectifier components provide reputable a/c to DC power conversion. Models include DD89N12K, DD89N14K, DD89N16K, and DD89N18K. These deal with high-power industrial needs. Each component sustains different voltage scores. The DD89N12K handles 1200V. The DD89N14K manages 1400V. The DD89N16K works with 1600V. The DD89N18K accommodates 1800V. All versions maintain high existing lots. This makes them ideal for heavy-duty systems.

These components include reduced onward voltage decrease. This reduces power loss. It enhances efficiency. They endure surge currents. This safeguards versus sudden power spikes. The durable construction fits severe environments. It ensures long-term operation. Thermal efficiency is enhanced. The base plate design allows simple heatsink installing. This prevents overheating.

Typical applications cover numerous sectors. Welding tools counts on these rectifiers. They give steady DC outcome. Motor drives use them in manufacturing facilities. They convert power for conveyor systems. Uninterruptible power materials incorporate these modules. They maintain backup power flow. Renewable resource systems employ them. Solar inverters and wind turbines benefit. Electric car chargers rely on them. They supply consistent billing power. Industrial battery chargers incorporate these components. They ensure reliable energy transfer.

Setup is uncomplicated. The portable design saves area. Upkeep demands are reduced. Reliability is proven in area tests. These components satisfy worldwide security standards. They offer cost-efficient efficiency. Users prevent frequent substitutes. This minimizes downtime.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

Here are 5 FAQs about diode rectifier modules DD89N12K, DD89N14K, DD89N16K, and DD89N18K:

What are these diode rectifier modules used for?

These modules convert alternating current to direct current in industrial equipment. They handle high-power applications like motor drives, power supplies, welding machines, and industrial battery chargers. Their robust design suits demanding environments.

What electrical ratings do these modules have?

All models handle an average forward current of 89A. Voltage ratings differ: DD89N12K supports 1200V, DD89N14K handles 1400V, DD89N16K manages 1600V, DD89N18K works with 1800V. Choose based on your circuit’s voltage needs.

How do I pick the right model for my project?

Match the module’s voltage rating to your system’s maximum reverse voltage. Add a safety margin. For a 1500V system, select DD89N16K (1600V rating). All models share the same current capacity. Verify your load requirements first.

Do these modules need special cooling?

Yes. These diodes generate heat during operation. Mount them on a heatsink using thermal paste. Ensure proper airflow. Check the datasheet for exact temperature limits. Overheating reduces performance or causes failure.

Can I use these in three-phase systems?

Yes. The DD89N series has a three-phase bridge configuration. They convert three-phase AC power efficiently. These modules are common in industrial motors, CNC machines, and heavy-duty power converters. Confirm your system’s phase requirements match the module design.

(DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K)

REQUEST A QUOTE

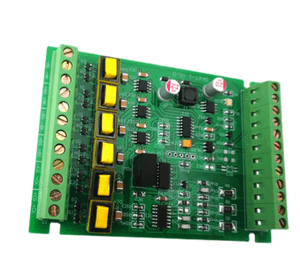

RELATED PRODUCTS

High reliability MFC200 1600V thyristor diode module

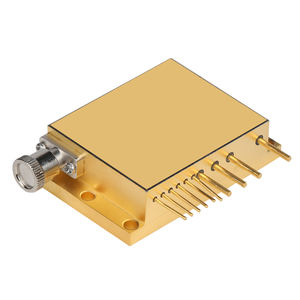

808nm 976nm customized High Power LD Module diode modul laser Fiber Coupled Pump Module

EASTCOM AMSKY V1-V6 VG V8 UV laser diode module 405nm CTP

B5819WS SOD-323 Schottky diode 600mV@1A 40V 1A Electronic Component Spot Inventory

1N4004 Rectifier Laser Dental Fiber Hair Removal Smd Portable Led Laser Diode Module Blue Silicon Controlled Rectifier 400~1600v