Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

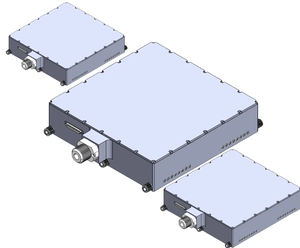

Overview of (B6C)2 Series Assemblies

(B6C)2 Series assemblies are engineered to provide superior performance in environments where accuracy, durability, and efficiency are paramount. They are designed to meet stringent industry standards and can be tailored to specific application requirements. The series is known for integrating complex functionalities into compact designs, reducing the overall footprint while enhancing operational capabilities.

These assemblies might include integrated circuits, sensors, actuators, connectors, and other electronic or mechanical components that work together seamlessly. The design philosophy behind (B6C)2 Series emphasizes modularity, allowing for easy upgrades and maintenance without compromising on performance.

Features of (B6C)2 Series Assemblies

High Precision: Manufactured with tight tolerances to ensure accurate operation in demanding conditions.

Compact Design: Integrates multiple components into a streamlined package, saving space and weight.

Durability and Reliability: Built to withstand harsh environments and offer long-term stable performance.

Integrated Functionality: Combines various functions into one assembly, reducing complexity and improving efficiency.

Customizable Options: Can be customized to fit specific application needs, including material selection, configuration, and performance parameters.

Ease of Installation: Designed for straightforward integration into existing systems, often featuring plug-and-play capability.

Advanced Materials: Utilizes cutting-edge materials for enhanced performance characteristics such as heat resistance, corrosion resistance, and strength.

Compliance with Standards: Adheres to relevant international and industry-specific standards for safety and performance.

Modular Design: Facilitates easy upgrades and maintenance, with components that can be individually replaced or updated.

Performance Optimization: Optimized for energy efficiency and performance, contributing to reduced operational costs over time.

(SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller)

Specification of SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller

The SZLH pellet mill roller shell assembly is a core spare component. It functions straight with the ring die. This pairing presses ground raw materials right into dense pellets. Animal feed mills and biomass plants utilize these parts greatly. They endure significant pressure and friction daily.

The roller covering setting up fits onto the primary shaft inside the pellet mill chamber. It usually holds two or three rollers. These rollers turn versus the internal surface of the stationary ring pass away. Feed material obtains forced via the die openings. This compression produces the final pellet shape. The rollers need to maintain continuous, firm contact with the die surface. Appropriate call makes certain effective pelleting and excellent pellet high quality.

The ring die is a huge, heavy steel cyndrical tube. Precision-drilled holes cover its internal area. Opening dimension and pattern determine pellet diameter and form. Ring passes away are made from special alloy steels. These steels stand up to wear and handle high pressure. Warm therapy makes the die surface incredibly difficult. This solidity prolongs the die’s functioning life.

Roller shells are additionally crafted from high-grade alloy steel. Their external surface area is set via heat treatment. This solidifying battles the consistent abrasion from raw materials. A challenging surface avoids premature wear and grooves. Grooves lower pelleting efficiency. The roller shell setting up includes bearings and seals. These parts allow smooth rotation and protect against dirt and moisture.

Regular evaluation of both roller coverings and the ring die is critical. Look for uneven wear patterns or deep scoring. Worn rollers or a worn die create poor quality pellets. They likewise squander energy. Changing rollers and the die with each other commonly produces the very best results. Utilizing mismatched parts causes unequal wear. This decreases overall tools life expectancy.

SZLH collection components are created for details mill models. Ensure compatibility before getting. Specific measurements and placing details issue. Real SZLH spare components guarantee correct fit and efficiency. Proper upkeep and prompt replacement of these settings up maintain your pellet mill running successfully.

(SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller)

Applications of SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller

SZLH pellet mill spare components like roller coverings and ring dies are crucial. They create the core pushing device. Basic material get in the pellet mill chamber. The roller shell assembly presses this material powerfully through the openings in the ring die. This action forms the feed or biomass right into thick pellets.

These components face consistent high stress and friction. They use down with time. Used roller coverings or ring passes away reason problems. Pellet high quality drops substantially. You see more fines and broken pellets. Manufacturing result decreases. Energy usage rises. Machine strain boosts. Replacing them at the right time is vital.

Picking authentic SZLH roller shells and ring passes away issues. They are engineered for specific fit and efficiency. Accuracy machining makes sure smooth procedure. Consistent pellet density and size rely on this. High-grade alloy steel construction uses remarkable wear resistance. You obtain longer life span. This decreases your downtime regularity. It decreases your overall operating expense per load produced.

Routine upkeep checks are required. Screen covering and pass away wear patterns. Change them prior to failure impacts manufacturing badly. Maintaining spare SZLH roller shell settings up and ring passes away prepared is wise. It avoids unexpected lengthy interruptions. You keep constant pellet output. Consistent item quality stays reliable.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller

Here’s the product content addressing 5 FAQs about SZLH pellet mill roller shell assemblies and ring dies. The roller shell assembly presses feed against the ring die. This makes pellets. It is a critical part. Replacement frequency depends on usage. Check every 500 operating hours. Look for visible wear. Replace if surfaces are uneven. Friction causes roller wear. Hard materials increase wear. Running the machine empty speeds up damage. Proper lubrication extends life. Inspect the ring die holes regularly. Replace if holes get larger. Replace if holes become uneven. Poor pellet shape means ring die problems. High energy consumption is another sign. Replacing one roller shell is possible. Replacing all rollers together is better. This maintains balance. Unbalanced rollers make bad pellets. They also damage the ring die faster. Always match roller shells to your ring die size. Use genuine parts for best fit. Store spares in dry conditions. This prevents rust. Keep spare rollers ready. This avoids long downtime.

(SZLH series pellet mill spare parts roller shell assembly pellet machine ring die roller)

REQUEST A QUOTE

RELATED PRODUCTS

Auto Spare Parts Truck/Trailer/Tractor Brake Shoe Kits & Assemblies for DAF/SAF/RENAULT Brake liner kits & Assemblies

custom 2 3 4 6 8 pin waterproof jst connector cable jst jwpf cable assembly 02R-JWPF-VSLE-S

China PTO Power Take Offs Hydraulic Pump Dump Truck Hydraulic System Assembly Pto

GOOD QUALITY N12B16A ENGINE ASSEMBLY FOR BMW

China original rebuild high quality Engine Assembly for BMW N20 N20B20 2.0L