Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of AC Switches of W Series

The W Series AC Switches are advanced solid-state switching devices designed for efficient and reliable control of alternating current (AC) loads. These switches offer a combination of high performance, compact design, and ease of integration into various electrical systems. They are engineered to handle significant power levels while minimizing heat generation and electromagnetic interference (EMI). The W Series is suitable for applications requiring precise and rapid control of AC power, such as industrial automation, lighting control, heating systems, and motor drives.

Features of AC Switches of W Series

- High Current Capacity: Designed to manage high-power AC loads, ensuring robust performance in demanding environments.

- Low Power Loss: Efficient switching mechanism reduces energy consumption and operational costs.

- Compact Size: Space-saving design facilitates easy installation and integration into existing systems.

- Fast Switching Speed: Enables quick response times, ideal for applications requiring rapid on/off cycles.

- Zero-Crossing Detection: Minimizes EMI by turning the switch on or off at zero voltage crossing points.

- Overload Protection: Built-in protection mechanisms safeguard against overcurrent and thermal overload conditions.

- Wide Operating Temperature Range: Stable performance across a broad temperature spectrum, enhancing reliability.

- Long Lifespan: Durable construction ensures long-term operation without frequent maintenance.

- User-Friendly Interface: Simple control interfaces make setup and operation straightforward.

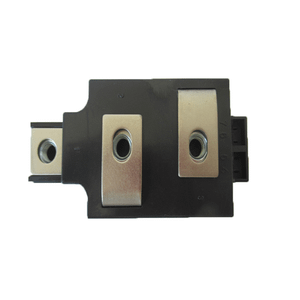

(BALDOR electric motor centrifugal switches)

Specification of BALDOR electric motor centrifugal switches

BALDOR electrical motor centrifugal buttons take care of beginning winding control in single-phase electric motors. These switches engage the begin winding when the electric motor starts. They detach it when the electric motor reaches a set speed. This activity ensures smooth procedure. BALDOR layouts these buttons for reliability. They operate in various commercial and industrial setups. The building and construction utilizes long lasting materials. Elements like the switch device and contacts withstand wear. State-of-the-art steel springtimes give consistent tension. Copper alloy calls make sure great electrical conductivity. These functions decrease arcing and prolong life span.

Centrifugal switches trigger based upon electric motor speed. The activation speed is pre-programmed at the manufacturing facility. Individuals do not require to change it. Deactivation typically occurs at 70-80% of the electric motor’s rated speed. This range avoids getting too hot. It likewise safeguards the beginning winding from damage. Consistent timing enhances motor efficiency. BALDOR examinations each button to verify performance. This makes sure compatibility with particular electric motor designs.

The buttons handle typical electric ratings. Many support 125V to 250V air conditioner systems. Current rankings vary by version. Usual choices consist of 10-15 amps. Higher-capacity buttons suit sturdy applications. The design reduces electric resistance. This decreases power loss throughout procedure. BALDOR uses switches for different motor sizes. Choices vary from tiny fractional horse power systems to larger multi-horsepower systems.

Setup is simple. The switches mount directly onto the electric motor shaft. Positioning with centrifugal weights is vital. Proper positioning guarantees exact speed detection. Upkeep demands are reduced. Regular evaluation checks for debris or get in touch with wear. Cleansing the contacts maintains efficiency. Substitute periods depend on use. Harsh settings may shorten lifespan.

BALDOR centrifugal buttons operate in challenging conditions. They hold up against temperatures as much as 150 ° C. Sealed models withstand dirt and wetness. This makes them appropriate for outside or dirty atmospheres. The buttons adhere to sector safety criteria. UL and CSA qualifications guarantee reliability. Customizable options include different spring stress or contact materials. These adjust to distinct motor needs.

The layout prioritizes safety and security. Protected housings prevent accidental get in touch with. Arcing reductions attributes lower fire threats. BALDOR gives detailed technological specs for each and every switch. Customers can match efficiency data to electric motor needs. This prevents inequalities that create premature failure. Technical support aids with choice and troubleshooting.

(BALDOR electric motor centrifugal switches)

Applications of BALDOR electric motor centrifugal switches

BALDOR electrical motor centrifugal buttons play a vital role in single-phase induction electric motors. These buttons help control the starting process. When the motor starts, the centrifugal button connects the begin winding. This produces the preliminary torque required for rotation. Once the motor gets to a certain rate, the button disconnects the start winding automatically. This avoids overheating and conserves power. BALDOR styles these buttons for dependability and lengthy life span.

These centrifugal buttons are utilized in many markets. Cooling and heating systems rely upon them for fans and blowers. The buttons ensure motors start smoothly and turn off the begin winding rapidly. This minimizes endure elements. Industrial machinery like pumps and compressors likewise make use of BALDOR centrifugal switches. They deal with high starting loads without failing. This maintains assembly line running effectively.

Agricultural devices benefits from these buttons also. Grain augers, watering pumps, and conveyor systems rely on regular electric motor performance. BALDOR changes job well in dirty or damp environments. They stand up to deterioration and mechanical tension. This makes them ideal for farming operations.

Home appliances like washing devices and air compressors use these switches. They guarantee peaceful procedure and avoid motor exhaustion. Individuals obtain longer home appliance life with less repair work. BALDOR’s layout concentrates on accuracy. The buttons turn on and deactivate at precise speeds. This precision safeguards the motor and boosts performance.

BALDOR centrifugal buttons are built with long lasting materials. Stainless steel parts and durable springs handle repeated use. Upkeep is minimal, lowering downtime. These buttons satisfy industry requirements for safety and security and performance. They are examined rigorously to guarantee integrity.

Electrical contractors and designers trust fund BALDOR for motor control options. The brand’s credibility for top quality makes these buttons a leading selection. Whether for industrial equipments or day-to-day home appliances, BALDOR centrifugal switches supply consistent outcomes. They maintain motors running efficiently, cut energy waste, and expand equipment lifespan.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality BALDOR electric motor centrifugal switches, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of BALDOR electric motor centrifugal switches

BALDOR electric motor centrifugal switches manage starting circuits in single-phase motors. These switches disconnect the start winding once the motor reaches a set speed. Here are five common questions about them.

What does a centrifugal switch do in a BALDOR motor? The switch cuts off the start winding after the motor spins fast enough. This action prevents overheating. It lets the motor run on the main winding alone.

How do I know if the centrifugal switch is bad? The motor might not start. It could hum without moving. Overheating happens often. The start winding stays engaged too long. These signs point to switch failure.

Can I fix a broken centrifugal switch? Replacing it works better than repairing. The switch has precise parts. Fixing it risks improper function. BALDOR offers exact replacements. Use them for safety.

How often should I check the centrifugal switch? Check during regular motor maintenance. Look for wear every six months. Heavy use needs more checks. Dirt or moisture speeds up damage. Clean the switch area often.

Do BALDOR centrifugal switches fit other motor brands? Maybe. Check size and specs first. Switches vary by model. BALDOR designs parts for their motors. Using them elsewhere might cause issues. Contact support for compatibility details.

(BALDOR electric motor centrifugal switches)

REQUEST A QUOTE

RELATED PRODUCTS

Chinakel KFC-W-19 series motoin detection switch small micro switch

EU TYPE P series wall switches regular 16A 220V colored electrical wall switch power electric on off switch

Crystal glass panel 3 Gang 2 way fluorescent indicator 16A On/Off light switch Stair wall switch

Chint wall switches NEW 7G series 4-gang 1-way switch 16A 250V wall switch 4 gang

Factory 10/100M unmanaged mini POE switch 6 port for cctv