Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

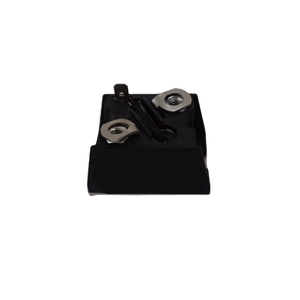

Overview of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

Specifications of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

This 200A 300V Thyristor Controlled Rectifier supplies vital DC power for anodic electrophoretic finish procedures. It transforms typical a/c line voltage right into carefully managed DC result. Exact voltage law is critical for finishing high quality. This unit takes care of demanding commercial environments.

The core electric specifications define its capacity. It provides a continuous DC result current of 200 Amperes. The maximum DC output voltage gets to 300 Volts. Input typically accepts typical three-phase AC power. The rectifier makes use of innovative thyristor innovation. This technology allows smooth, stepless control of the result voltage and existing. Operators change the DC outcome specifically. This modification enhances the coating deposition process.

Control features guarantee trustworthy operation. The unit consists of thorough overload security. Short-circuit defense safeguards the system. Over-temperature protection stops damages. An integrated control panel takes care of thyristor firing. This board ensures steady output under differing load problems. Remote user interfaces are basic. Operators incorporate the rectifier easily right into bigger layer systems. Keeping an eye on outcome criteria is straightforward.

The physical building and construction prioritizes durability. A sturdy steel room safeguards internal elements. Interior parts are safely installed. This placing withstands vibration common in factories. Effective forced-air air conditioning maintains risk-free operating temperatures. This cooling is essential for sustained high-current procedure. Electric terminals are clearly labeled. This labeling streamlines installation and upkeep electrical wiring. Security certifications fulfill industrial standards.

This rectifier delivers regular, trusted DC power. It makes sure uniform covering density and adhesion. Refine repeatability enhances considerably. Power efficiency is a vital benefit. Thyristor control reduces thrown away power. Operational costs reduce with time. The robust design reduces downtime. Upkeep demands are minimized.

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

Applications of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

This thyristor regulated rectifier takes care of 200 amps and 300 volts. It’s constructed for anodic electrophoretic finishing processes. This approach down payments repaint onto steel components making use of electrical power. The rectifier transforms a/c power to DC power. It controls this DC power really precisely. This control is essential for top notch finishings.

The rectifier manages the voltage related to the covering tank. Stable voltage makes sure the paint down payments evenly on the parts. This prevents slim spots or thick spots. Uniform layer density is critical for rust protection and appearance. The thyristor innovation permits fast changes. It reacts instantly to modifications in the bath chemistry or part load. This keeps the layer procedure secure.

It gives consistent present thickness across all components in the container. This is essential for complicated shapes. Every surface requires the correct amount of current. Excellent current distribution prevents issues like pinholes or roughness. The rectifier keeps this also when coating many components simultaneously.

This system saves power. It only makes use of the power needed for the exact coating work. This lowers electrical power costs. The exact control likewise lessens paint waste. Operators obtain the finishing right the very first time. This cuts down on rework and turns down. Manufacturing runs efficiently and efficiently.

The durable layout manages the demanding factory atmosphere. It works accurately for continuous manufacturing schedules. Maintenance requirements are low. This rectifier supplies reputable efficiency day in day out. It ensures the finishing procedure fulfills stringent high quality criteria regularly. Factories accomplish far better results with this tools.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

Here are 5 FAQs about the 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating:

What is this rectifier for? This device controls DC power for anodic electrophoretic coating. It changes AC power into stable, adjustable DC. Precise DC voltage is vital for consistent coating thickness and quality on parts.

Why use thyristor control? Thyristors offer very fine adjustment of the output DC voltage. This level of control is needed for the coating process. It ensures the right deposition rate and adhesion. Manual taps or basic diodes cannot achieve this precision.

Why is low ripple important? Ripple refers to leftover AC variation in the DC output. High ripple causes coating defects like pinholes or uneven layers. This rectifier minimizes ripple. It provides smooth DC essential for high-quality, defect-free finishes.

What protection does it offer? The unit protects itself and the coating tank. It includes safety features like over-current cut-off and short-circuit shutdown. This prevents damage during faults. It also has a Faraday shield. This isolates sensitive control circuits from electrical noise in the harsh coating environment.

Is maintenance difficult? This rectifier design focuses on reliability. Key parts are accessible. Standard cooling methods like fans or heat sinks are used. This keeps things simple. Routine checks are straightforward. The goal is maximum uptime for the coating line.

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

REQUEST A QUOTE

RELATED PRODUCTS

new SKKQ 1500/14E diode module

60APU04 400V 60A TO247 Fast recovery rectifiers diode

Anbon 1A 400V 150ns DFR1G SOD-123 Package Smd Fast Recovery Rectifier Diode

B540C-13-F Diode 40 V 5A Surface Mount SMC Diodes Rectifiers Schottky Diodes

Enerkey in stock Ideal Diode Module 100V 100A Battery Charging Anti Reverse Connection Power Protection Board Potting module