Thyristors Dalam Talian | Semikonduktor Kuasa Berkualiti Tinggi

PARAMETER PRODUK

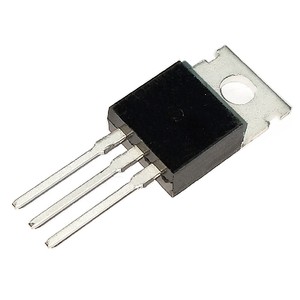

Penerangan

Gambaran Keseluruhan Diod Penerus

Diod penerus ialah peranti semikonduktor yang digunakan terutamanya untuk menukar arus ulang alik (AC) ke dalam arus terus (DC). Mereka membenarkan arus mengalir dengan mudah dalam satu arah sambil menghalangnya ke arah yang bertentangan. Sifat satu arah ini menjadikannya komponen penting dalam bekalan kuasa, pemprosesan isyarat, dan pelbagai litar elektronik. Diod penerus boleh mengendalikan pelbagai arus dan voltan, menjadikannya serba boleh untuk pelbagai aplikasi.

Ciri-ciri Diod Penerus

Kekonduksian Sehala: Memudahkan pengaliran arus dalam satu arah sahaja, berkesan menyekat arus songsang.

Pengendalian Arus Tinggi: Direka untuk membawa arus ke hadapan yang besar, sesuai untuk aplikasi berkuasa tinggi.

Voltan Songsang Puncak (PIV): Boleh menahan voltan terbalik yang tinggi tanpa rosak.

Penurunan Voltan Hadapan Rendah: Meminimumkan kehilangan tenaga sebagai haba, meningkatkan kecekapan.

Masa Pemulihan Cepat: Beralih dengan pantas daripada keadaan konduktor kepada keadaan tidak konduktor, bermanfaat untuk aplikasi frekuensi tinggi.

Kestabilan Terma: Mengekalkan prestasi merentasi julat suhu yang luas, memastikan kebolehpercayaan dalam pelbagai keadaan.

Saiz Padat: Faktor bentuk kecil memudahkan penyepaduan ke dalam reka bentuk elektronik padat.

Kos-Efektif: Menyediakan penyelesaian yang menjimatkan untuk keperluan penukaran AC-ke-DC.

Pelbagai Pakej: Tersedia dalam pelbagai pilihan pembungkusan untuk memenuhi keperluan pemasangan yang berbeza.

(rectifier for electroplating,three phase diode bridge rectifier)

Specification of rectifier for electroplating,three phase diode bridge rectifier

This three-phase diode bridge rectifier gives steady DC power for electroplating work. It manages difficult industrial problems well. It changes three-phase a/c power into smooth DC power. This DC power is vital for putting steel coatings onto components.

The rectifier accepts standard three-phase air conditioning input voltage. Common levels are 380V or 415V A/C. Outcome DC voltage changes within a wide range. Normal arrays are 0-12V or 0-24V DC. Outcome DC current is high. Options consist of 1000A, 2000A, 3000A, even greater. Specific specifications match your plating tank size and procedure requirements.

Effective diodes develop the core bridge circuit. These diodes take care of the high existing circulation efficiently. They create heat. Air air conditioning or water cooling removes this warm. Air-cooled systems use huge followers. Water-cooled kinds require a cooling water. Water air conditioning deals with bigger loads better.

Control is straightforward and reputable. Hand-operated handles or electronic panels established the output voltage and present. Operators adjust these for the particular plating task. Meters show the actual DC voltage and existing outcome. This lets you monitor efficiency frequently.

Safety is built-in. Over-current defense journeys if lots surpasses secure restrictions. Over-temperature protection shuts things down if cooling stops working. Short-circuit security defend against unintentional mistakes. These attributes safeguard both the rectifier and your plating arrangement.

The system sits in a strong steel enclosure. This protects the internal components. Terminals are big and sturdy. They attach thick DC busbars to the plating container anodes and cathodes. Input utilizes basic AC cable access. The layout focuses on easy access for maintenance.

(rectifier for electroplating,three phase diode bridge rectifier)

Applications of rectifier for electroplating,three phase diode bridge rectifier

Electroplating demands DC power. Air conditioner power comes from the grid. Rectifiers transform a/c to DC. They are essential for electroplating. The 3 stage diode bridge rectifier is a common option. It deals with commercial power requires well. This rectifier uses 6 diod. They attach in a bridge pattern. Three air conditioning input stages feed into it. The diodes guide the present flow. They just enable existing in one direction. This action converts all 3 air conditioning stages into DC result.

This DC power feeds the electroplating bath. The metal ions relocate in the direction of the workpiece. They deposit onto its surface area. A steady DC supply is crucial. It controls the plating density. It regulates the plating top quality. The 3 stage diode bridge offers benefits. Its result surge is less than single-phase kinds. Smoother DC suggests far better plating results. It utilizes the input power effectively. Less energy is lost as warm. This saves money on power. These rectifiers are really robust. Diodes are straightforward and trustworthy parts. They manage high currents easily. Upkeep demands are low. Downtime is reduced.

Industrial electroplating lines require high power. 3 phase systems give this power effectively. The bridge rectifier scales well. It matches large plating storage tanks. It matches high-speed plating procedures. Voltage and present control are crucial. Modern rectifiers include adjustable controls. Operators set the voltage specifically. They set the existing density specifically. This makes certain regular layering quality set after set. Air conditioning is important for hefty loads. Air cooling down usually is sufficient. Water cooling manages extreme task cycles. Rectifiers are developed tough for factory atmospheres. They stand up to dirt and chemicals. Trustworthy DC power is the foundation of excellent electroplating.

Profil Syarikat

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) ialah salah satu perusahaan terkemuka dalam teknologi elektronik kuasa dan produk kuasa, yang terlibat sepenuhnya dalam membangunkan penyongsang suria, transformer, pengawal selia voltan, kabinet pengedaran, thyristor, modul, diod, pemanas, dan peranti elektronik atau semikonduktor lain. Kami akan komited untuk menyediakan pengguna yang berkualiti tinggi, produk yang cekap dan perkhidmatan yang bertimbang rasa.

Ia menerima pembayaran melalui Kad Kredit, T/T, West Union, dan Paypal. PDDN akan menghantar barangan kepada pelanggan di luar negara melalui FedEx, DHL, melalui laut, atau melalui udara. If you want high-quality rectifier for electroplating,three phase diode bridge rectifier, sila hantarkan pertanyaan kepada kami; kami akan berada di sini untuk membantu anda.

Kaedah Pembayaran

L/C, T/T, Western Union, Paypal, Kad Kredit dll.

Penghantaran

Melalui laut, melalui udara, secara ekspres, sebagai permintaan pelanggan.

Keadaan Penyimpanan

1) Simpan dalam persekitaran yang kering pada suhu bilik.

2) Elakkan suhu lembap dan tinggi.

3) Gunakan segera selepas membuka beg pembungkusan dalam.

5 FAQs of rectifier for electroplating,three phase diode bridge rectifier

Here are five key questions about three-phase diode bridge rectifiers for electroplating:

What makes a three-phase rectifier better than single-phase for electroplating? Three-phase rectifiers handle much more power efficiently. They deliver smoother DC output voltage. This smoother power means better quality plating. You get more consistent metal deposition. Single-phase units struggle with high-power jobs.

How does the diode bridge actually work? It uses six diodes. These diodes are arranged in a specific bridge circuit. They let current flow in only one direction. Alternating current (AC) comes in from the three power lines. The diodes switch the current path constantly. Direct current (DC) comes out. This DC powers the plating tank.

How much power can these rectifiers handle? They are built for tough industrial jobs. Standard units manage from a few hundred amps up to many thousands of amps. Output voltages typically range between 12 and 24 volts DC. You pick the size based on your plating tank size. Match the rectifier to your specific plating current needs.

Why is low ripple voltage important? Ripple is the small leftover AC variation in the DC output. High ripple is bad. It causes uneven plating. You might get rough deposits or burnt spots on parts. Three-phase diode bridges naturally have lower ripple. This gives you cleaner, more uniform plating results.

Do these rectifiers need special cooling? ya, absolutely. Passing huge currents creates significant heat. This heat must be removed. Most industrial units use either forced air cooling with big fans or water cooling. Proper cooling prevents damage. It ensures the rectifier runs reliably for years. Always check the cooling system works.

(rectifier for electroplating,three phase diode bridge rectifier)

MINTA SEBUT HARGA

PRODUK BERKAITAN

Rectifier Diode 500A 2000V For Beauty Machine ZP500A2000V

DF01S1 BRIDGE RECTIFIER DIODE

Electronic components original rectifier single diode in stock

(Bridge Rectifiers) DF150AB160

New Delivery Feature High Current Rectifier Capabilities Robust Performance U1A-U1M High Efficiency Rectifiers