Tiristori tiešsaistē | Augstas kvalitātes jaudas pusvadītāji

PRODUKTA PARAMETRI

Apraksts

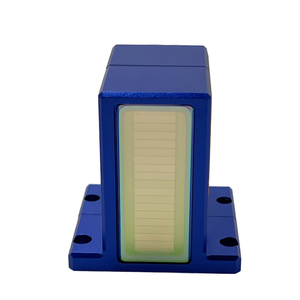

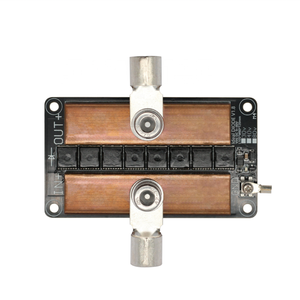

Overview of 808nm diode laser bars for module stack

Diodes moduļi ir komplekti, kas sastāv no vairākām diodēm, kas ir iesaiņotas kopā, lai izveidotu vienu, viegli uzstādāma vienība. Tos plaši izmanto jaudas elektronikā labošanai (maiņstrāvas pārveidošana līdzstrāvā), aizsargājot ķēdes no pārsprieguma un reversās strāvas, un daudzas citas lietojumprogrammas. Diožu moduļos parasti ir dažāda veida diodes, piemēram, ātrās atkopšanas diodes, Šotkija diodes, utt., lai atbilstu īpašām pieteikuma prasībām.

Features of 808nm diode laser bars for module stack

Augsta uzticamība: Integrējot vairākas diodes, tiek samazināts vienas komponentes atteices risks.

Vienkāršots dizains: Moduļu izmantošana var samazināt PCB telpas prasības un vienkāršot ķēdes dizainu.

Augsta efektivitāte: Dažos diodes moduļos tiek izmantoti progresīvi materiāli un tehnoloģijas, lai nodrošinātu zemāku tiešā sprieguma kritumu un augstāku efektivitāti.

Laba siltuma izkliede: Daudzi moduļi ir izstrādāti ar efektīviem siltuma izkliedes ceļiem, lai nodrošinātu stabilu darbību lielas jaudas apstākļos.

Viegli uzstādīt un uzturēt: Standartizēts iepakojums padara uzstādīšanu un nomaiņu vieglāku un ātrāku.

(808nm diode laser bars for module stack)

Specification of 808nm diode laser bars for module stack

These 808nm diode laser bars are built for stacking into high-power modules. They deliver the specific wavelength needed for pumping solid-state lasers. Wavelength stability is critical. Our bars hold tight wavelength control across different operating conditions. This ensures efficient energy transfer to your gain medium.

Power output is scalable. We offer bars from tens of watts up to several hundred watts per bar. You choose the power level matching your module’s requirements. High electro-optical efficiency is standard. More electrical power converts into useful laser light. Less power becomes waste heat. This reduces your cooling load.

Effective cooling is essential. These bars generate significant heat at high power. We design them for direct liquid cooling. Water flows directly over the heatsink surface. This removes heat efficiently. Proper cooling extends the laser bar’s lifetime. It also maintains stable performance.

Beam quality matters for good coupling. Our bars provide a fast axis beam with low divergence. This divergence is typically under 40 degrees full width. The slow axis divergence is higher. Beam quality parameters are optimized for standard optical coupling schemes. You get reliable beam characteristics bar after bar.

We test every bar rigorously. Tests include power output, wavelength, efektivitāti, and near-field pattern. We check for defects. Reliability is proven under demanding conditions. Long operational lifetimes are expected with proper cooling and drive currents. These bars are ready for integration into your stacked module design.

(808nm diode laser bars for module stack)

Applications of 808nm diode laser bars for module stack

808nm diode laser bars are key components for building powerful laser modules. These bars emit light at 808 nanometri. This specific wavelength is very useful in industry. Multiple bars get stacked together to create a module. This stacking is how we achieve high output power levels.

The 808nm wavelength is ideal for pumping solid-state lasers. Neodymium-doped crystals like Nd:YAG absorb 808nm light very well. The stacked bars efficiently transfer energy into these crystals. The crystal then produces its own powerful laser beam. This is the main way these diode bars get used.

Stacking many bars close together creates a lot of heat. Good cooling is absolutely essential. Modules need advanced cooling systems. Water cooling is common for handling the thermal load. Keeping the bars cool ensures stable operation. It also extends the working life of the laser module.

Beam quality from a single bar is good along one direction. Stacking bars affects the overall beam shape. The beam becomes less round. Special optics are needed to shape the beam. These optics focus the light for the application. Beam shaping is critical for effective use.

Direct material processing is another application. The 808nm light itself can heat materials. Stacked modules deliver enough power for tasks like surface treatment. Plastic welding and metal hardening are possible examples. The direct diode approach offers efficiency benefits.

Reliability is a major advantage. Diode laser bars are known for long lifetimes. Properly cooled and operated stacks last thousands of hours. This reliability is vital for industrial equipment. Downtime for repairs costs money.

Uzņēmuma profils

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) ir viens no vadošajiem uzņēmumiem jaudas elektronikas tehnoloģiju un enerģijas produktu jomā, kas ir pilnībā iesaistīts saules invertoru izstrādē, transformatori, sprieguma regulatori, sadales skapji, tiristori, moduļi, diodes, sildītāji, un citas elektroniskas ierīces vai pusvadītāji. Mēs būsim apņēmušies nodrošināt lietotājiem augstu kvalitāti, efektīvi produkti un uzmanīgs serviss.

Tas pieņem maksājumus ar kredītkarti, T/T, Rietumu savienība, un Paypal. PDDN nosūtīs preces klientiem ārzemēs, izmantojot FedEx, DHL, pa jūru, vai pa gaisu. If you want high-quality 808nm diode laser bars for module stack, lūdzu, sūtiet mums pieprasījumus; mēs būsim šeit, lai jums palīdzētu.

Maksājumu veidi

L/C, T/T, Western Union, Paypal, Kredītkarte utt.

Sūtījums

Pa jūru, pa gaisu, ar eksprespasta palīdzību, pēc klientu pieprasījuma.

Uzglabāšanas apstākļi

1) Uzglabāt sausā vidē istabas temperatūrā.

2) Izvairieties no mitruma un augstas temperatūras.

3) Izlietot uzreiz pēc iekšējā iepakojuma maisiņa atvēršanas.

5 FAQs of 808nm diode laser bars for module stack

Here are five common questions about 808nm diode laser bars for module stacks:

What makes 808nm diode laser bars suitable for module stacks?

808nm light is strongly absorbed by materials like Nd:YAG. This makes pumping solid-state lasers efficient. The wavelength is reliable for industrial use. Diode laser bars offer high power density. Stacking them creates very powerful modules.

How long do these 808nm laser bars typically last?

Lifetime depends heavily on operating conditions. Pareiza dzesēšana ir ļoti svarīga. Drive current levels matter. Stable electrical supply helps. Under recommended conditions, expect thousands of hours. Exceeding specs shortens life significantly.

What power levels can one 808nm laser bar achieve?

Single bars deliver high power. Outputs range from tens to hundreds of watts. Exact power depends on the bar design. Cooling efficiency limits maximum power. Stacking multiple bars multiplies the total output power substantially.

Why is thermal management so important for stacked modules?

Diode laser bars generate substantial heat. Heat degrades performance. Too much heat shortens the bar’s life. Thermal lensing can ruin beam quality. Effective cooling maintains stability. It ensures consistent power output. Good heat sinks and coolers are essential.

What key specifications should I check when selecting bars for stacking?

Verify the wavelength accuracy. Ensure the spectral width is narrow. Check the output power per bar. Confirm the operating current and voltage. Examine the fast-axis divergence angle. Assess the fill factor. Look at the cooling requirements. Compatibility with the stack holder is necessary.

(808nm diode laser bars for module stack)

PASŪTĪT CĒNĀJUMU

SAISTĪTIE PRODUKTI

High-Precision 8x30mm Aluminium Mini Laser Diode Module for Fast Cutting in Construction, New Condition, 5MW Optical Power

Yokden Genset Parts taisngrieža tilta diode MXG 50-15 136mm liela izmēra taisngriežu diodes

DF100LB160 DF100LB DF100 100A 1600V diode IGBT barošanas modulis DF100LB160

L03S400D15 IGBT modulis, diode/tranzistors, pastiprināšanas smalcinātājs,

3-5v 450nm Blue Line lāzerdiodes modulis 80mw