Thyristors Online | Héich Qualitéit Power Semiconductors

PRODUIT PARAMETER

Beschreiwung

Iwwersiicht vun Rectifier Diodes

Gläichretterdioden sinn Hallefleitgeräter déi haaptsächlech benotzt gi fir den Ofwiesselungsstroum ëmzewandelen (AC) an direkt Stroum (DC). Si erlaben de Stroum einfach an eng Richtung ze fléien, wärend se an déi entgéintgesate Richtung blockéieren. Dës unidirektional Eegeschafte mécht se wesentlech Komponenten an Energieversuergung, Signal Veraarbechtung, a verschidde elektronesch Kreesleef. Gläichretterdioden kënnen eng breet Palette vu Stroum a Spannungen handhaben, mécht se villsäiteg fir vill Uwendungen.

Features vu Rectifier Diodes

Unidirectional Konduktivitéit: Erliichtert de Stroum nëmmen an eng Richtung, effektiv blockéiert ëmgedréint Stroum.

Héich Stroum Ëmgank: Entworf fir substantiell Forward Strom ze droen, gëeegent fir héich-Muecht Uwendungen.

Peak Inverse Volt (PIV): Kann héich ëmgedréint Spannungen widderstoen ouni ze briechen.

Niddereg Forward Volt Drop: Miniméiert Energieverloscht als Hëtzt, d'Effizienz verbesseren.

Schnell Erhuelung Zäit: Iwwergank séier vun Dirigent an net-dirigent Staaten, profitabel fir héich Frequenz Uwendungen.

Thermesch Stabilitéit: Erhalen Leeschtung iwwer eng breet Temperatur Gamme, garantéiert Zouverlässegkeet a verschiddene Konditiounen.

Kompakt Gréisst: Klenge Formfaktor erliichtert d'Integratioun a kompakt elektronesch Designen.

Käschten-effikass: Bitt eng wirtschaftlech Léisung fir AC-zu-DC Konversiounsbedürfnisser.

Varietéit vu Packagen: Verfügbar a verschidde Verpackungsoptiounen fir verschidde Montagefuerderunge ze passen.

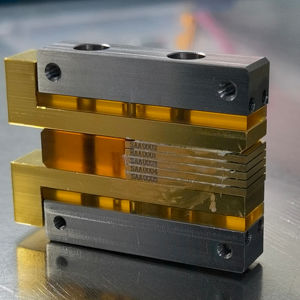

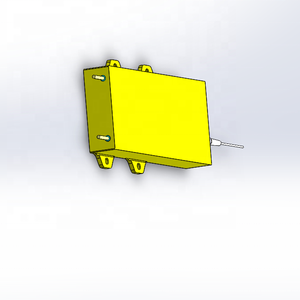

(12V-4000A plating rectifier with reversing)

Specification of 12V-4000A plating rectifier with reversing

This rectifier supplies high power for requiring electroplating tasks. It supplies straight current result. The voltage changes efficiently from 0 zu 12 volts DC. It deals with huge currents as much as 4000 amperes. This fits heavy commercial applications like large tank plating.

A crucial feature is automated reversing. This feature switches the existing direction instantly. It cycles in between forward (anodic) and reverse (cathodic) flow. The timing is flexible. You control the forward time period. You additionally control the reverse time duration. This cycle repeats continually throughout procedure. Reversing assists stop usual plating troubles. It minimizes undesirable build-up on sides. It minimizes tree-like growths. It battles roughness. This results in smoother, much more also metal down payments. Layer quality boosts considerably. Components look much better and last much longer.

The device utilizes dependable silicon regulated rectifier (SCR) Technologie. SCRs switch power efficiently. They offer exact control over output. The design consists of solid transformers. These deal with the high existing safely. Cooling is crucial at this power level. The rectifier makes use of forced air cooling. Powerful followers maintain parts at risk-free temperatures. This avoids overheating throughout lengthy changes. Security circuits are constructed in. These guard against issues like brief circuits. They guard against overloads. They defend against overheating. This protects both the rectifier and your plating bath.

Digital meters present operating worths clearly. You see outcome voltage frequently. You see outcome present continuously. This permits very easy tracking. The control board provides straightforward changes. Set voltage simply. Set existing limits just. Set up the reversing times conveniently. The unit is built difficult for manufacturing facility conditions. It holds up against the severe plating setting. It stands up to rust well. Maintenance demands are reduced.

(12V-4000A plating rectifier with reversing)

Applications of 12V-4000A plating rectifier with reversing

This powerful 12V-4000A plating rectifier with reversing deals with demanding industrial steel finishing jobs. It takes care of thick, top notch electroplating deposits. You require this for chrome plating big parts like hydraulic cylinders or machine components. It layers nickel onto auto bumpers and trim pieces effectively. The high current makes certain quickly copper layering for circuit board manufacturing. It deposits zinc dependably onto steel fasteners and equipment for rust security.

The turning around function is important. It occasionally switches the present instructions. This breaks up irregular deposits during plating. You obtain smoother, brighter chrome and nickel coatings. Reversing protects against rough, plain layers. It likewise quits “burning” at sharp edges. This is crucial for decorative items requiring ideal look.

Turning around allows electrocleaning and removing as well. You remove old plating, rust, or range from steel surface areas prior to recoating. This prepares components perfectly for new plating. It recovers useful elements for reuse. The procedure cleans up detailed forms thoroughly.

This rectifier powers large layering tanks successfully. Its 4000A ability matches high-volume production lines. Factories layering automobile components count on it. Aerospace providers use it for important elements. Job stores dealing with varied layering tasks discover it flexible. The robust design takes care of continuous commercial procedure. It provides stable, precise DC power vital for constant plating high quality. You control voltage, presentéieren, and timing cycles accurately. This ensures repeatable outcomes set after batch. The device withstands harsh chemical plant environments.

Firma Profil

PDDN Photoelectron Technology Co., Ltd., Ltd.(sales@pddn.com) ass eng vun de féierende Entreprisen a Kraaftelektronik Technologie a Kraaftprodukter, déi voll an der Entwécklung vu Solarinverter involvéiert ass, transformers, Volt reegler, Verdeelung cabinets, thyristors, Moduler, dioden, Heizungen, an aner elektronesch Apparater oder semiconductors. Mir wäerten verpflichte Benotzer mat héich-Qualitéit ze bidden, effizient Produkter a virsiichteg Service.

Et akzeptéiert Bezuelen iwwer Kreditkaart, T/T, West Unioun, an Paypal. PDDN wäert d'Wueren u Clienten iwwerséiesch iwwer FedEx schécken, DHL, vum Mier, oder duerch Loft. If you want high-quality 12V-4000A plating rectifier with reversing, weg schéckt eis Ufroen; mir wäerten hei sinn fir Iech ze hëllefen.

Bezuelmethoden

L/C, T/T, Western Union, Paypal, Kreditkaart etc.

Sendung

Mam Mier, duerch Loft, duerch express, wéi Clienten Ufro.

Stockage Konditiounen

1) Store an engem dréchen Ëmfeld bei Raumtemperatur.

2) Vermeiden Feuchtigkeit an héich Temperaturen.

3) Benotzt direkt no der Ouverture vun der banneschten Verpackungsbeutel.

5 FAQs of 12V-4000A plating rectifier with reversing

Hei sinn 5 FAQs about the 12V-4000A Plating Rectifier with Reversing:

What does the reversing function do?

The reversing function switches the current direction. This is vital for electroplating processes needing metal stripping or specific deposit qualities. It helps remove imperfections during plating cycles. Smoother, more uniform metal layers result. This improves adhesion and reduces rejects.

How is the massive heat managed?

This rectifier generates significant heat at full load. A powerful internal cooling system handles it. Industrial-grade fans pull air through large heat sinks. This keeps critical components within safe operating temperatures. Consistent cooling prevents overheating shutdowns and extends equipment life.

Are safety features included?

Jo, multiple safety features protect both the machine and operators. Standard protections guard against overloads, kuerz Circuit, and overheating. Emergency stop buttons provide instant shutdown capability. Proper grounding and clear safety markings are essential. Always follow all safety protocols.

Can I control the plating cycle precisely?

Jo, precise control is a key feature. Digital interfaces allow exact setting of voltage, aktuell, timing, and reverse cycle parameters. Operators program specific sequences for different plating jobs. Repeatable accuracy ensures consistent plating results batch after batch.

What maintenance does it need?

Regular maintenance keeps the rectifier reliable. Check and clean air filters and cooling fans frequently. Inspect electrical connections for tightness and corrosion. Monitor output performance for any drift. Schedule professional inspections annually. Preventative care avoids unexpected downtime and costly repairs.

(12V-4000A plating rectifier with reversing)

Ufro engem ZITAT

Zesummenhang PRODUITEN

High Current 3000A rectifier 12vdc For Gravure Cylinder With IGBT Module

New Rectifier R-6 Good Quality Plastic 25A 1000V Diode 25a10 25A10

Rectifier Diode 95A 1200V 95PFR120 95PF120 New in Stock

Plug-in Inline Gliichtdiode 1N4007 DO-41

3000A 12V Rectifier Water Cooling Type Rectifier with Timing Function Chrome Electroplating Rectifier