사이리스터 온라인 | 고품질 전력 반도체

제품 매개변수

설명

정류기 다이오드 개요

정류 다이오드는 주로 교류 전류를 변환하는 데 사용되는 반도체 장치입니다. (교류) 직류로 (DC). 전류가 한 방향으로 쉽게 흐르도록 하고 반대 방향으로는 전류를 차단합니다.. 이러한 단방향 특성으로 인해 전원 공급 장치의 필수 구성 요소가 됩니다., 신호 처리, 그리고 각종 전자회로. 정류기 다이오드는 광범위한 전류 및 전압을 처리할 수 있습니다., 수많은 응용 분야에 다용도로 사용 가능.

정류 다이오드의 특징

단방향 전도도: 한 방향으로만 전류 흐름을 촉진합니다., 역전류를 효과적으로 차단.

고전류 처리: 상당한 순방향 전류를 전달하도록 설계됨, 고전력 애플리케이션에 적합.

피크 역전압 (PIV): 파손 없이 높은 역전압을 견딜 수 있음.

낮은 순방향 전압 강하: 열로 인한 에너지 손실 최소화, 효율성 향상.

빠른 복구 시간: 전도 상태에서 비전도 상태로 빠르게 전환, 고주파 애플리케이션에 유리함.

열 안정성: 넓은 온도 범위에서 성능 유지, 다양한 조건에서 신뢰성 보장.

컴팩트한 사이즈: 소형 폼 팩터로 컴팩트한 전자 설계에 통합이 용이함.

비용 효율적: AC-DC 변환 요구 사항에 맞는 경제적인 솔루션 제공.

다양한 패키지: 다양한 장착 요구 사항에 맞게 다양한 포장 옵션으로 제공.

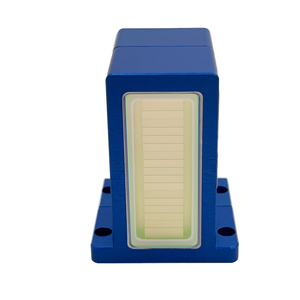

(펄스 역정류기)

Specification of Pulse reverse rectifier

The Pulse Opposite Rectifier is designed for electroplating and metal finishing. It regulates existing instructions to boost covering high quality. The system deals with numerous metals like gold, silver, nickel, and copper. It matches industries needing specific steel deposition.

The rectifier has flexible present output. The range is 0 에게 1000 앰프. Voltage changes between 0 그리고 24 볼트. This versatility sustains various procedure demands. Users can set ahead and turn around pulse times. Pulse frequency ranges from 50 Hz to 2000 Hz. Adjusting these settings enhances layering rate and harmony.

The unit includes a digital user interface. Operators input parameters through a touchscreen. Real-time tracking reveals voltage, 현재의, and temperature level. Informs activate if worths surpass safe restrictions. This prevents tools damage. Information logging tracks process background for analysis.

Cooling uses air or fluid approaches. Air cooling help reduced power applications. Fluid cooling takes care of high-power procedures. Both options maintain secure temperatures throughout long runs. The unit is corrosion-resistant. Materials hold up against rough chemical settings.

Security functions include overload defense and short-circuit avoidance. Emergency situation quit switches are easily accessible. The design satisfies international electric standards. Certifications cover CE and RoHS compliance.

The rectifier links to existing production lines. Standard interaction procedures allow combination. Remote control is possible through software program. Maintenance is marginal. Components are modular for fast replacement.

Dimensions differ by version. Small versions save room in congested centers. Larger units handle industrial-scale work. Weight varies from 50 kg to 500 kg. Mounting choices consist of flooring stands or wall surface braces.

Power input approves 220V or 380V AIR CONDITIONING. Effectiveness rankings go beyond 90%. Energy-saving modes reduce prices throughout still periods. Running temperatures range from 0 ° C ~ 40 ℃. Storage space problems allow -20 ° C ~ 60 ℃. Service warranty insurance coverage covers three years. Technical assistance is readily available worldwide. Extra components are shipped within two days. Training materials include manuals and video guides.

(펄스 역정류기)

Applications of Pulse reverse rectifier

Pulse reverse rectifiers are electronic gadgets made use of to control the instructions and timing of electric existing. They switch over current circulation in between onward and turn around settings rapidly. These systems play a vital role in markets requiring accurate control over electrochemical procedures.

One major application is electroplating and metal ending up. Pulse reverse rectifiers improve finish quality by rotating present instructions. This eliminates contaminations from metal surfaces. It makes certain also deposition of materials like gold or nickel. The result is stronger rust resistance and better appearance.

Electronics making counts on these rectifiers for creating printed circuit card (PCBs). They help develop fine conductive paths on boards. Exact present control stops over-etching. It keeps tight resistances required for contemporary electronic devices. Semiconductor construction uses comparable principles for transferring slim films on silicon wafers.

Renewable energy systems utilize pulse reverse rectifiers in power conversion. Solar panels and wind turbines produce variable DC or a/c power. These gadgets support outcome for grid compatibility. They adjust voltage and present to match storage or circulation requirements. Effectiveness improvements reduce energy loss during conversion.

Automotive and aerospace industries apply this modern technology for layer vital parts. Engine parts and turbine blades call for sturdy surfaces. Pulse opposite rectifiers allow consistent layers that withstand high temperatures and friction. This extends part life expectancy under severe operating conditions.

Wastewater therapy plants make use of these systems for steel recovery. Industrial wastewater frequently consists of important steels like copper or silver. The rectifiers separate and recover these materials via controlled electrolysis. This minimizes ecological effect. It decreases prices by reusing sources.

Pulse reverse rectifiers adjust to different voltage and current demands. Adjustable setups match certain commercial demands. Their small style enables integration right into existing equipment. Upkeep is minimal as a result of robust building and construction. Operators take advantage of real-time tracking attributes for procedure modifications.

회사 프로필

PDDN 광전자 기술 유한 회사, 주식회사(sales@pddn.com) 전력 전자 기술 및 전력 제품 분야의 선도적인 기업 중 하나입니다., 태양광 인버터 개발에 전적으로 참여하고 있습니다., 변압기, 전압 조정기, 배포 캐비닛, 사이리스터, 모듈, 다이오드, 히터, 및 기타 전자 장치 또는 반도체. 우리는 사용자에게 고품질을 제공하기 위해 최선을 다할 것입니다, 효율적인 제품과 사려 깊은 서비스.

신용카드 결제가 가능합니다., 티/티, 웨스트유니언, 그리고 페이팔. PDDN은 FedEx를 통해 해외 고객에게 상품을 배송합니다., DHL, 바다로, 아니면 비행기로. If you want high-quality Pulse reverse rectifier, 문의사항을 보내주세요; 우리는 당신을 돕기 위해 여기 있을 것입니다.

결제 방법

신용장, 티/티, 웨스턴 유니언, 페이팔, 신용카드 등.

선적

바다로, 비행기로, 급행으로, 고객의 요청에 따라.

보관 조건

1) 실온의 건조한 환경에 보관하세요..

2) 습기와 고온을 피하십시오.

3) 내부 포장백 개봉 후 즉시 사용.

5 FAQs of Pulse reverse rectifier

What is a pulse reverse rectifier?

A pulse reverse rectifier is a power supply device used mainly in electroplating and electrochemical processes. It provides pulsed direct current with periodic polarity reversal. This technology allows better control over metal deposition and surface finish. It improves plating quality and process efficiency.

How does a pulse reverse rectifier work?

The device switches the current direction between forward and reverse cycles rapidly. Forward cycles deposit metal onto the workpiece. Reverse cycles dissolve excess deposits or impurities. Parameters like pulse frequency and duty cycle are adjustable. Users customize these settings to match specific application needs.

What are the advantages over traditional rectifiers?

Pulse reverse rectifiers offer precise control over plating thickness and uniformity. They reduce material waste and energy consumption. They minimize hydrogen embrittlement in sensitive metals. Coating adhesion and surface smoothness improve significantly. Equipment lifespan often increases due to reduced overheating risks.

Where are pulse reverse rectifiers commonly used?

They are popular in industries requiring high-quality metal coatings. Examples include electronics manufacturing for circuit boards, automotive parts for corrosion resistance, and jewelry for decorative finishes. They also serve in aerospace components and medical device production. Anodizing and metal etching processes frequently use this technology.

What factors should be considered when selecting a pulse reverse rectifier?

Key factors include output current and voltage ranges, frequency adjustment capabilities, and compatibility with specific plating solutions. User interface simplicity matters for operational ease. Reliability and after-sales support ensure minimal downtime. Budget constraints and long-term maintenance costs should also influence the decision.

(펄스 역정류기)