Thyristor á netinu | Hágæða máttur hálfleiðarar

VÖRUFRÆÐIR

Lýsing

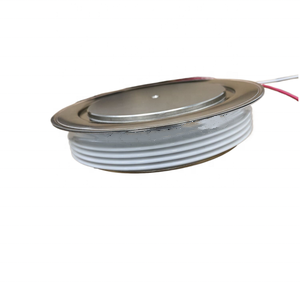

Yfirlit yfir afriðandi díóða

Afriðardíóða eru hálfleiðaratæki sem notuð eru fyrst og fremst til að breyta riðstraumi (AC) í jafnstraum (DC). Þeir leyfa straumi að flæða auðveldlega í eina átt en hindra hann í gagnstæða átt. Þessi einátta eiginleiki gerir þá að nauðsynlegum hlutum í aflgjafa, merkjavinnsla, og ýmsar rafrásir. Afriðunardíóður geta séð um margs konar strauma og spennu, sem gerir þær fjölhæfar fyrir fjölmörg forrit.

Eiginleikar Rectifier díóða

Einátta leiðni: Auðveldar straumflæði aðeins í eina átt, hindrar í raun bakstraum.

Meðhöndlun hástraums: Hannað til að bera mikla framstrauma, hentugur fyrir aflmikil notkun.

Hámarks andhverf spenna (PIV): Þolir háa bakspennu án þess að bila.

Lágt áframspennufall: Lágmarkar orkutap sem hita, bæta skilvirkni.

Fljótur batatími: Breytist fljótt frá leiðandi yfir í ekki stjórnandi ríki, gagnlegt fyrir hátíðni forrit.

Hitastöðugleiki: Viðheldur afköstum yfir breitt hitastig, tryggja áreiðanleika við mismunandi aðstæður.

Fyrirferðarlítil stærð: Lítill formstuðull auðveldar samþættingu í þéttri rafrænni hönnun.

Kostnaðarhagkvæm: Veitir hagkvæma lausn fyrir AC-til-DC umbreytingarþörf.

Fjölbreytni pakka: Fáanlegt í mörgum umbúðum til að passa við mismunandi uppsetningarkröfur.

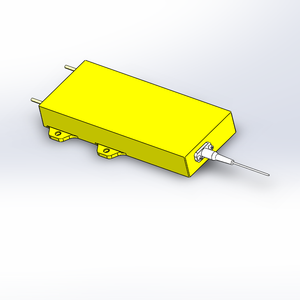

(12V 1500A afrakstur rafhúðun afriðari með tímasetningaraðgerð Rafrofsaflgjafi Afriðli fyrir loftkælingu)

Specification of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This 12V 1500A high power electroplating rectifier provides severe existing for demanding plating jobs. It gives a stable 12 volts DC result. The system takes care of approximately 1500 amps continually. Air air conditioning keeps everything running cool also under hefty lots. Followers draw air over interior parts. This design stays clear of overheating throughout lengthy plating cycles. Upkeep stays straightforward without fluid coolant systems.

An integrated timing feature is a significant advantage. Operators established specific plating durations straight on the device. The rectifier immediately turns off after the set time. This makes certain regular layer thickness each time. It stops over-plating blunders. Workers do not require to constantly view the clock. Productivity improves significantly.

The rectifier supplies uncomplicated procedure. Controls are clear and easy to use. Readjust voltage and present setups with easy handles or switches. Review outputs on clear digital displays. Establishing the timer is just as basic. New customers learn it rapidly. Arrangement calls for very little training.

Safety and integrity are core features. The design includes defense against overloads and brief circuits. This safeguards both the tools and the plating bath. The system utilizes robust industrial-grade components. These parts stand up to rough plating store atmospheres. The steel unit withstands rust. It likewise protects against dirt and dampness ingress. Electric safety accreditations are standard.

This power supply fits massive electroplating procedures. It deals with huge parts or high-volume barrel layering effectively. The high amperage guarantees quick deposition rates. Constant outcomes minimize product waste. The timing function includes vital process control. Manufacturing facilities see far better throughput and reduced costs.

(12V 1500A afrakstur rafhúðun afriðari með tímasetningaraðgerð Rafrofsaflgjafi Afriðli fyrir loftkælingu)

Applications of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

This effective 12V 1500A electroplating rectifier delivers serious power for demanding commercial procedures. It provides stable, high-current DC outcome vital for constant metal deposition. The incorporated timing function is a major benefit. Operators set exact plating periods for each batch. This automation guarantees repeatable results batch after batch. It eliminates uncertainty. It boosts product consistency substantially.

Air cooling maintains the system running reliably under hefty tons. Followers dissipate warmth efficiently. This layout avoids intricate liquid cooling systems. Upkeep stays easier. Downtime decreases. The robust construction takes care of challenging factory settings. It stands up to warmth, óhreinindi, and vibration common in layering stores.

This rectifier masters high-throughput electroplating applications. It’s excellent for plating big surface areas promptly. Think auto components, heavy machinery components, or large steel fixtures. The high 1500A capacity handles thick down payments successfully. It matches difficult chromium plating, nickel plating, and copper plating procedures requiring significant power. The secure outcome keeps consistent present density. This leads to attire, high-grade metal coverings.

The timer feature automates the plating cycle. Employees load components. They begin the process. The device competes the set time. It then turns off instantly. This avoids over-plating. It conserves power. It optimizes bathroom life. It releases operators for other tasks. Accuracy timing makes sure every part gets exactly the appropriate layer density.

Integrity is crucial in production. This air-cooled design uses reliable operation. Regular DC result protects against layer problems. Integrated defense circuits guard against overloads and shorts. This shields your important workpieces. It safeguards the rectifier itself. The unit gives the muscle needed for industrial-scale electroplating. Its timing feature adds crucial procedure control.

Fyrirtækissnið

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) er eitt af leiðandi fyrirtækjum í rafeindatækni og rafmagnsvörum, sem tekur fullan þátt í þróun sólarinvertara, spennar, spennustillir, dreifiskápar, tyristor, einingar, díóða, hitari, og önnur rafeindatæki eða hálfleiðara. Við munum leggja metnað okkar í að veita notendum hágæða, skilvirkar vörur og tillitssama þjónustu.

Það tekur við greiðslu með kreditkorti, T/T, Vesturbandalagið, og Paypal. PDDN mun senda vörurnar til viðskiptavina erlendis í gegnum FedEx, DHL, með sjó, eða með flugi. If you want high-quality 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier, vinsamlegast sendu okkur fyrirspurnir; við munum vera hér til að hjálpa þér.

Greiðslumáti

L/C, T/T, Western Union, Paypal, Kreditkort o.fl.

Sending

Við sjó, með flugi, með tjáningu, eins og viðskiptavinir óska eftir.

Geymsluskilyrði

1) Geymið í þurru umhverfi við stofuhita.

2) Forðist raka og háan hita.

3) Notist strax eftir að innri umbúðapokann hefur verið opnaður.

5 FAQs of 12V 1500A High Power Electroplating Rectifier with Timing Function Electrolysis Power Supply Rectifier Air cooling Rectifier

What is this rectifier used for? This rectifier powers industrial electroplating and electrolysis. It delivers stable DC power. Factories use it for metal coating tasks. It handles chrome, nikkel, zinc plating. It manages heavy-duty operations smoothly. It fits large-scale production needs.

Hverjir eru helstu eiginleikarnir? It supplies 12 volt og 1500 magnara. This offers robust power for demanding jobs. It includes a built-in timing function. This controls process duration precisely. It uses air cooling technology. Air cooling simplifies the setup. It avoids water-based systems entirely. This reduces maintenance efforts. It ensures long-term reliability. It saves factory floor space too.

How does the timing function work? Set the desired time upfront. Choose hours, minutes, or seconds. The unit runs for that exact period. It shuts down automatically afterward. This guarantees uniform plating results. It minimizes energy waste. It removes timing mistakes. Workers handle other duties during operation.

Why choose air cooling? Air cooling relies on internal fans. Fans circulate air through the machine. This dissipates heat effectively. It beats water cooling in simplicity. No plumbing or water supply is necessary. It cuts operational expenses. It performs in arid or gritty environments. It resists freezing in cold climates. It provides consistent cooling always.

What safety measures are included? Multiple safeguards are integrated. Overload protection interrupts power during excessive current. Short-circuit protection responds instantly to faults. Over-temperature protection switches off the unit if overheated. These features prevent equipment damage. They shield workers from harm. The design prioritizes workplace safety. The construction ensures durability.

(12V 1500A afrakstur rafhúðun afriðari með tímasetningaraðgerð Rafrofsaflgjafi Afriðli fyrir loftkælingu)