Thyristors dị n'ịntanetị | Semiconductors ike dị elu

PRAMETERS ngwaahịa

Nkọwa

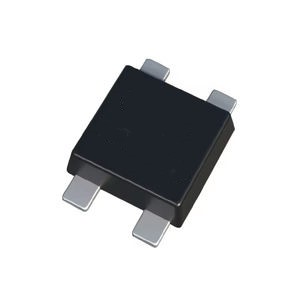

Nchịkọta nke Diodes Rectifier

Diode rectifier bụ ngwaọrụ semiconductor eji eme ihe maka ịtụgharị ọzọ ugbu a (AC) banye kpọmkwem ugbu a (DC). Ha na-ekwe ka ihe dị ugbu a na-eru n'ụzọ dị mfe n'otu ụzọ ma na-egbochi ya n'akụkụ nke ọzọ. Ngwongwo unidirectional a na-eme ka ha dị mkpa na akụrụngwa ọkụ, nhazi mgbaàmà, na sekit eletrọnịkị dị iche iche. Diode rectifier nwere ike ijikwa oke mmiri na voltaji dị iche iche, na-eme ka ha dị iche iche maka ọtụtụ ngwa.

Atụmatụ nke Rectifier Diodes

Omume Unidirectional: Na-eme ka ọ dị ugbu a n'otu ụzọ naanị, na-egbochi azụ azụ ugbu a nke ọma.

Ijikwa dị elu ugbu a: Emebere ya ka ọ buru nnukwu mmiri na-aga n'ihu, adabara maka ngwa ike dị elu.

Onu kacha elu voltaji (PIV): Nwere ike idi elu reverse voltaji na-enweghị imebi.

Mbelata voltaji dị ala: Na-ebelata ọnwụ ike dị ka okpomọkụ, imeziwanye arụmọrụ.

Oge mgbake ngwa ngwa: Na-agbanwe ngwa ngwa site na-eduzi gaa na steeti ndị na-adịghị eduzi, bara uru maka ngwa ngwa dị elu.

Thermal kwụsie ike: Na-ejigide arụmọrụ n'ofe oke okpomọkụ, n'ịhụ na a pụrụ ịdabere na ọnọdụ dị iche iche.

Nha kọmpat: Obere ụdị ihe na-eme ka ntinye aka n'ime atụmatụ eletrọnịkị kọmpat.

Ọnụ-dị irè: Na-enye ngwọta akụ na ụba maka mkpa ntụgharị AC-to-DC.

Ụdị ngwugwu dị iche iche: Dị na otutu nhọrọ nkwakọ ngwaahịa dabara dị iche iche arịọnụ chọrọ.

(rectifier for electroplating,three phase diode bridge rectifier)

Specification of rectifier for electroplating,three phase diode bridge rectifier

This three-phase diode bridge rectifier gives steady DC power for electroplating work. It manages difficult industrial problems well. It changes three-phase a/c power into smooth DC power. This DC power is vital for putting steel coatings onto components.

The rectifier accepts standard three-phase air conditioning input voltage. Common levels are 380V or 415V A/C. Outcome DC voltage changes within a wide range. Normal arrays are 0-12V or 0-24V DC. Outcome DC current is high. Options consist of 1000A, 2000A, 3000A, even greater. Specific specifications match your plating tank size and procedure requirements.

Effective diodes develop the core bridge circuit. These diodes take care of the high existing circulation efficiently. They create heat. Air air conditioning or water cooling removes this warm. Air-cooled systems use huge followers. Water-cooled kinds require a cooling water. Water air conditioning deals with bigger loads better.

Control is straightforward and reputable. Hand-operated handles or electronic panels established the output voltage and present. Operators adjust these for the particular plating task. Meters show the actual DC voltage and existing outcome. This lets you monitor efficiency frequently.

Safety is built-in. Over-current defense journeys if lots surpasses secure restrictions. Over-temperature protection shuts things down if cooling stops working. Short-circuit security defend against unintentional mistakes. These attributes safeguard both the rectifier and your plating arrangement.

The system sits in a strong steel enclosure. This protects the internal components. Terminals are big and sturdy. They attach thick DC busbars to the plating container anodes and cathodes. Input utilizes basic AC cable access. The layout focuses on easy access for maintenance.

(rectifier for electroplating,three phase diode bridge rectifier)

Applications of rectifier for electroplating,three phase diode bridge rectifier

Electroplating demands DC power. Air conditioner power comes from the grid. Rectifiers transform a/c to DC. They are essential for electroplating. The 3 stage diode bridge rectifier is a common option. It deals with commercial power requires well. This rectifier uses 6 diodes. They attach in a bridge pattern. Three air conditioning input stages feed into it. The diodes guide the present flow. They just enable existing in one direction. This action converts all 3 air conditioning stages into DC result.

This DC power feeds the electroplating bath. The metal ions relocate in the direction of the workpiece. They deposit onto its surface area. A steady DC supply is crucial. It controls the plating density. It regulates the plating top quality. The 3 stage diode bridge offers benefits. Its result surge is less than single-phase kinds. Smoother DC suggests far better plating results. It utilizes the input power effectively. Less energy is lost as warm. This saves money on power. These rectifiers are really robust. Diodes are straightforward and trustworthy parts. They manage high currents easily. Upkeep demands are low. Downtime is reduced.

Industrial electroplating lines require high power. 3 phase systems give this power effectively. The bridge rectifier scales well. It matches large plating storage tanks. It matches high-speed plating procedures. Voltage and present control are crucial. Modern rectifiers include adjustable controls. Operators set the voltage specifically. They set the existing density specifically. This makes certain regular layering quality set after set. Air conditioning is important for hefty loads. Air cooling down usually is sufficient. Water cooling manages extreme task cycles. Rectifiers are developed tough for factory atmospheres. They stand up to dirt and chemicals. Trustworthy DC power is the foundation of excellent electroplating.

Nkọwapụta Ụlọ ọrụ

Ụlọ ọrụ PDDN Photoelectron Technology Co., Ltd., Ltd.(sales@pddn.com) bụ otu n'ime ụlọ ọrụ na-eduga na teknụzụ ọkụ eletrik na ngwaahịa ike, nke na-etinye aka n'ụzọ zuru ezu n'ịmepụta ihe ntụgharị anyanwụ, ihe ntụgharị, ndị na-achịkwa voltaji, nkesa kabinet, thyristors, modul, diodes, ndị na-ekpo ọkụ, na ngwaọrụ eletrọnịkị ndị ọzọ ma ọ bụ semiconductors. Anyị ga-agba mbọ ịnye ndị ọrụ oke mma, ngwaahịa na-arụ ọrụ nke ọma na ọrụ nlezianya.

Ọ na-anabata ịkwụ ụgwọ site na kaadị kredit, T/T, West Union, na Paypal. PDDN ga-ebuga ngwa ahịa ndị ahịa na mba ofesi site na FedEx, DHL, site n'oké osimiri, ma ọ bụ site na ikuku. If you want high-quality rectifier for electroplating,three phase diode bridge rectifier, biko zitere anyị ajụjụ; anyị ga-anọ ebe a inyere gị aka.

Ụzọ ịkwụ ụgwọ

L/C, T/T, Western Union, Paypal, Kaadị kredit wdg.

Mbupu

Site n'oké osimiri, site n'ikuku, site na nkwuwa okwu, dị ka ndị ahịa na-arịọ.

Ọnọdụ Nchekwa

1) Chekwaa na ebe akọrọ na ụlọ okpomọkụ.

2) Zere iru mmiri na oke okpomọkụ.

3) Jiri ozugbo imepechara akpa nkwakọ ngwaahịa dị n'ime.

5 FAQs of rectifier for electroplating,three phase diode bridge rectifier

Here are five key questions about three-phase diode bridge rectifiers for electroplating:

What makes a three-phase rectifier better than single-phase for electroplating? Three-phase rectifiers handle much more power efficiently. They deliver smoother DC output voltage. This smoother power means better quality plating. You get more consistent metal deposition. Single-phase units struggle with high-power jobs.

How does the diode bridge actually work? It uses six diodes. These diodes are arranged in a specific bridge circuit. They let current flow in only one direction. Alternating current (AC) comes in from the three power lines. The diodes switch the current path constantly. Direct current (DC) comes out. This DC powers the plating tank.

How much power can these rectifiers handle? They are built for tough industrial jobs. Standard units manage from a few hundred amps up to many thousands of amps. Output voltages typically range between 12 na 24 volts DC. You pick the size based on your plating tank size. Match the rectifier to your specific plating current needs.

Why is low ripple voltage important? Ripple is the small leftover AC variation in the DC output. High ripple is bad. It causes uneven plating. You might get rough deposits or burnt spots on parts. Three-phase diode bridges naturally have lower ripple. This gives you cleaner, more uniform plating results.

Do these rectifiers need special cooling? Ee, absolutely. Passing huge currents creates significant heat. This heat must be removed. Most industrial units use either forced air cooling with big fans or water cooling. Proper cooling prevents damage. It ensures the rectifier runs reliably for years. Always check the cooling system works.

(rectifier for electroplating,three phase diode bridge rectifier)

RỊỌRỌ OKWU

Ngwaahịa ndị metụtara

new rectifier diode 1000v FR107 FR157 in4001

DO-4 25HF 25A 1200V Rectifier Diode Normal Regular Polarity

S2AA-13-F 1.5A 50V Rectifier Diode High Performance Product

25HF120 rectifier stud diode 25A Rectifier Diodes

Fast Recovery Rectifier Diode RURG3020C