Tiristè sou entènèt | Semi-kondiktè pouvwa-wo kalite

PARAMÈT PWODWI

Deskripsyon

Overview of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

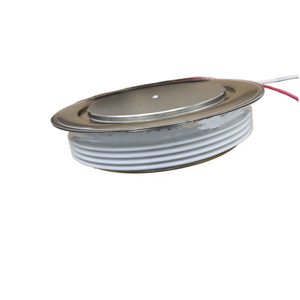

Modil dyod yo se asanble ki gen plizyè dyod ki pake ansanm pou fòme yon sèl, inite fasil pou enstale. Yo lajman ki itilize nan elektwonik pouvwa pou redresman (konvèti AC an DC), Pwoteje sikui kont survoltaj ak aktyèl ranvèse, ak anpil lòt aplikasyon. Modil dyod tipikman gen diferan kalite dyod, tankou dyod rekiperasyon rapid, Dyòd Schottky, elatriye., pou satisfè kondisyon espesifik aplikasyon yo.

Features of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

Segondè fyab: Pa entegre plizyè dyod, risk pou yon sèl echèk eleman redwi.

Senplifye konsepsyon: Sèvi ak modil ka diminye kondisyon espas PCB ak senplifye konsepsyon sikwi.

Segondè efikasite: Gen kèk modil dyòd ki sèvi ak materyèl avanse ak teknoloji pou bay pi ba gout vòltaj pi devan ak pi wo efikasite.

Bon dissipation chalè: Anpil modil yo fèt ak chemen dissipation chalè efikas pou asire operasyon ki estab nan kondisyon gwo pouvwa.

Fasil pou enstale epi kenbe: Anbalaj estanda fè enstalasyon ak ranplasman pi fasil ak pi vit.

(High-Kalite itilize Blue Dot Lazè Dyòd Modil pou Gravure presizyon ak koupe nan konstriksyon)

Specification of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

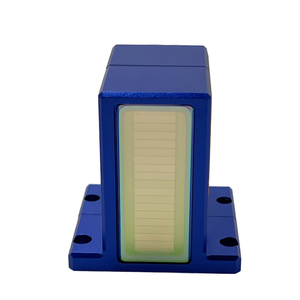

This premium used Blue Dot Laser Diode Component is developed for precision engraving and reducing in construction applications. It provides reliable efficiency with a power result of 10W and operates at a wavelength of 450nm. The blue laser light beam guarantees sharp focus, making it ideal for in-depth work on products like wood, plastik, and thin steels. The module maintains stable output as a result of sophisticated temperature control, reducing power waste throughout prolonged use.

The beam top quality is optimized with an M two element listed below 1.3, making certain marginal divergence for constant results. This enables specific control over reducing deepness and inscribing patterns. The module includes flexible focus settings, enabling modification for various product thicknesses. Customers can switch over in between constant wave and pulsed settings, adapting to tasks needing speed or great information.

Built with industrial-grade components, the component stands up to extreme environments typical in construction websites. Its portable layout allows easy assimilation into existing machinery or mobile setups. The real estate is made from aluminum alloy, giving sturdiness while maintaining the device lightweight. A built-in cooling system prevents overheating, extending the module’s lifespan also under heavy workloads.

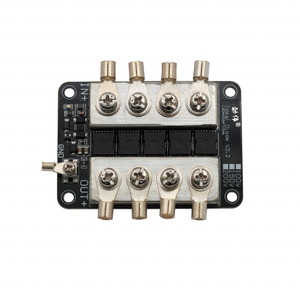

Security features include automatic shut-off throughout power variations and safety covers to block roaming laser discharges. The module deals with conventional power products (12-24V DC), guaranteeing compatibility with the majority of equipment. It supports typical control user interfaces like PWM and TTL, streamlining links to CNC systems or software application.

Each unit undergoes extensive inspection prior to resale. Examinations inspect output stability, light beam positioning, and cooling down performance. Minor surface area wear may exist, yet inner parts fulfill initial efficiency requirements. The component ships with a standard calibration report and recommended maintenance standards.

This utilized laser diode component provides a cost-efficient option for specialists needing high accuracy without new-equipment costs. Its design focuses on user safety and functional flexibility. Compatibility with preferred engraving software program guarantees seamless process integration. Upkeep is uncomplicated, with replacement parts commonly readily available. Normal cleansing of lenses and heat sinks maintains efficiency with time.

(High-Kalite itilize Blue Dot Lazè Dyòd Modil pou Gravure presizyon ak koupe nan konstriksyon)

Applications of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

High-grade utilized blue dot laser diode modules are reliable tools for accuracy engraving and reducing in construction. These components provide focused laser light beams for precise material processing. They work well on steels, plastics, wood, and composites. Their portable design suits lots of industrial systems. Construction groups use them for comprehensive jobs like noting dimensions, creating tags, or reducing small parts.

These laser components create constant power output. This ensures clean cuts and sharp inscriptions. They deal with tough materials like steel or concrete surface areas. The blue dot wavelength supplies better exposure throughout operation. Workers change setups easily for different task needs. This versatility quicken workflows on-site.

Toughness matters in building environments. Utilized components are evaluated for efficiency. They stand up to dirt, resonances, and temperature level modifications. Upkeep is simple. Replacement components are widely offered. This decreases downtime during critical tasks.

Cost cost savings issue. Top notch utilized modules cost less than new ones. They execute virtually the very same. Budget-conscious companies upgrade devices without spending beyond your means. The components utilize power effectively. They reduced power costs gradually.

Security features prevent accidents. Integrated air conditioning systems quit overheating. Safety real estates secure employees from laser direct exposure. Automatic shut-off features trigger during malfunctions.

Mobility is another benefit. The modules connect to handheld gadgets or taken care of machines. Groups move them in between work websites. They operate in tight areas or large locations.

Precision inscription helps with long-term markings. Instances consist of serial numbers, safety warnings, or style patterns. Cutting applications consist of cutting pipes, shaping tiles, or changing architectural components. Mistakes decrease due to the laser’s precision.

Training demands are minimal. Operators discover controls promptly. Technical support is often included with utilized components. Company supply troubleshooting overviews or repair work services.

These laser diode modules fulfill market criteria. They blend right into existing workflows. Projects end up quicker with less errors. Product waste decreases. Results look specialist every time.

Investing in made use of blue dot laser systems enhances building quality. It supports long-lasting project needs. Groups attain far better results without high expenses.

Konpayi Profile

PDDN Photoelectron Teknoloji Co., Ltd.(sales@pddn.com) se youn nan antrepwiz dirijan yo nan teknoloji elektwonik pouvwa ak pwodwi pouvwa, ki se konplètman patisipe nan devlope varyateur solè, transfòmatè, regilatè vòltaj, kabinèt distribisyon, tiristor, modil yo, dyod, aparèy chofaj, ak lòt aparèy elektwonik oswa semi-conducteurs. Nou pral pran angajman pou bay itilizatè yo bon jan kalite, pwodwi efikas ak sèvis atansyon.

Li aksepte peman atravè kat kredi, T/T, West Union, ak Paypal. PDDN pral voye machandiz yo bay kliyan lòt bò dlo atravè FedEx, DHL, pa lanmè, oswa pa lè. If you want high-quality High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction, tanpri voye nou kesyon; nou pral la pou ede w.

Metòd Peman

L/C, T/T, Western Union, Paypal, Kat kredi elatriye.

chajman

Pa lanmè, pa lè, pa eksprime, jan kliyan mande.

Kondisyon Depo

1) Sere nan yon anviwònman sèk nan tanperati chanm.

2) Evite tanperati imid ak wo.

3) Sèvi ak imedyatman apre ouvèti sak anbalaj anndan an.

5 FAQs of High-Quality Used Blue Dot Laser Diode Module for Precision Engraving and Cutting in Construction

What makes this used blue dot laser diode module suitable for construction tasks? This module delivers precise control for engraving and cutting materials like wood, plastik, and metal. Its high-powered blue laser ensures clean edges and detailed designs. The durable build handles tough job site conditions.

Are used laser modules reliable for professional projects? Wi. Each module undergoes strict testing to confirm performance and safety. Components like the diode and cooling system are inspected for wear. Units failing quality checks are rejected. This ensures reliability matching new models at lower costs.

How often does the module need maintenance? Clean the lens and vents weekly to prevent dust buildup. Check electrical connections monthly for corrosion or looseness. Replace cooling fans every 12 months. Following these steps minimizes downtime and extends the module’s lifespan.

Can it integrate with existing construction machinery? The module fits standard mounting brackets and connects via universal ports like USB or 24V DC. Compatibility with common software (e.g., LightBurn, LaserGRBL) allows quick setup. Confirm voltage requirements match your equipment before purchasing.

What safety features protect users during operation? The housing blocks excess heat and scattered light. A built-in emergency stop shuts the laser off instantly if overheating occurs. Always use protective goggles and ensure the work area is ventilated. Follow local safety guidelines to avoid accidents.

Does the laser lose power over time? Output remains stable if maintenance is consistent. Gradual power loss signals diode aging, typically after 8,000–10,000 hours. Regular calibration checks maintain accuracy. Replace the diode if performance drops below 85% of its original capacity.

(High-Kalite itilize Blue Dot Lazè Dyòd Modil pou Gravure presizyon ak koupe nan konstriksyon)

DEMANDE YON PREVO

PWODWI ki gen rapò

DIODE MODIL RECTIFIER DD89N12K DD89N14K DD89N16K DD89N18K

low power consumption high light efficiency light emitting diode

OPT101 Light Analog Light Intensity Sensor Module Single Chip Photoelectric Diode 14KHz CJMCU-101

1N4007 Original DIODE STD DO-41 1000V 1A Single dyod konpozan elektwonik sikwi entegre Bom SMT PCBA sèvis

L03S400D15 Module IGBT, diode/transistor, boost chopper,