Tiristè sou entènèt | Semi-kondiktè pouvwa-wo kalite

PARAMÈT PWODWI

Deskripsyon

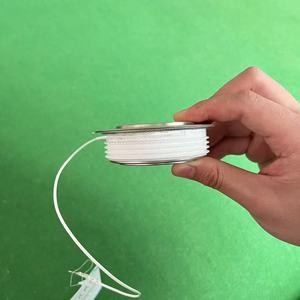

Overview of 808nm diode laser bars for module stack

Modil dyod yo se asanble ki gen plizyè dyod ki pake ansanm pou fòme yon sèl, inite fasil pou enstale. Yo lajman ki itilize nan elektwonik pouvwa pou redresman (konvèti AC an DC), Pwoteje sikui kont survoltaj ak aktyèl ranvèse, ak anpil lòt aplikasyon. Modil dyod tipikman gen diferan kalite dyod, tankou dyod rekiperasyon rapid, Dyòd Schottky, elatriye., pou satisfè kondisyon espesifik aplikasyon yo.

Features of 808nm diode laser bars for module stack

Segondè fyab: Pa entegre plizyè dyod, risk pou yon sèl echèk eleman redwi.

Senplifye konsepsyon: Sèvi ak modil ka diminye kondisyon espas PCB ak senplifye konsepsyon sikwi.

Segondè efikasite: Gen kèk modil dyòd ki sèvi ak materyèl avanse ak teknoloji pou bay pi ba gout vòltaj pi devan ak pi wo efikasite.

Bon dissipation chalè: Anpil modil yo fèt ak chemen dissipation chalè efikas pou asire operasyon ki estab nan kondisyon gwo pouvwa.

Fasil pou enstale epi kenbe: Anbalaj estanda fè enstalasyon ak ranplasman pi fasil ak pi vit.

(808nm diode laser bars for module stack)

Specification of 808nm diode laser bars for module stack

These 808nm diode laser bars are built for stacking into high-power modules. They deliver the specific wavelength needed for pumping solid-state lasers. Wavelength stability is critical. Our bars hold tight wavelength control across different operating conditions. This ensures efficient energy transfer to your gain medium.

Power output is scalable. We offer bars from tens of watts up to several hundred watts per bar. You choose the power level matching your module’s requirements. High electro-optical efficiency is standard. More electrical power converts into useful laser light. Less power becomes waste heat. This reduces your cooling load.

Effective cooling is essential. These bars generate significant heat at high power. We design them for direct liquid cooling. Water flows directly over the heatsink surface. This removes heat efficiently. Proper cooling extends the laser bar’s lifetime. It also maintains stable performance.

Beam quality matters for good coupling. Our bars provide a fast axis beam with low divergence. This divergence is typically under 40 degrees full width. The slow axis divergence is higher. Beam quality parameters are optimized for standard optical coupling schemes. You get reliable beam characteristics bar after bar.

We test every bar rigorously. Tests include power output, wavelength, efficiency, and near-field pattern. We check for defects. Reliability is proven under demanding conditions. Long operational lifetimes are expected with proper cooling and drive currents. These bars are ready for integration into your stacked module design.

(808nm diode laser bars for module stack)

Applications of 808nm diode laser bars for module stack

808nm diode laser bars are key components for building powerful laser modules. These bars emit light at 808 nanometers. This specific wavelength is very useful in industry. Multiple bars get stacked together to create a module. This stacking is how we achieve high output power levels.

The 808nm wavelength is ideal for pumping solid-state lasers. Neodymium-doped crystals like Nd:YAG absorb 808nm light very well. The stacked bars efficiently transfer energy into these crystals. The crystal then produces its own powerful laser beam. This is the main way these diode bars get used.

Stacking many bars close together creates a lot of heat. Good cooling is absolutely essential. Modules need advanced cooling systems. Water cooling is common for handling the thermal load. Keeping the bars cool ensures stable operation. It also extends the working life of the laser module.

Beam quality from a single bar is good along one direction. Stacking bars affects the overall beam shape. The beam becomes less round. Special optics are needed to shape the beam. These optics focus the light for the application. Beam shaping is critical for effective use.

Direct material processing is another application. The 808nm light itself can heat materials. Stacked modules deliver enough power for tasks like surface treatment. Plastic welding and metal hardening are possible examples. The direct diode approach offers efficiency benefits.

Fyab se yon gwo avantaj. Diode laser bars are known for long lifetimes. Properly cooled and operated stacks last thousands of hours. This reliability is vital for industrial equipment. Downtime for repairs costs money.

Konpayi Profile

PDDN Photoelectron Teknoloji Co., Ltd.(sales@pddn.com) se youn nan antrepwiz dirijan yo nan teknoloji elektwonik pouvwa ak pwodwi pouvwa, ki se konplètman patisipe nan devlope varyateur solè, transfòmatè, regilatè vòltaj, kabinèt distribisyon, tiristor, modil yo, dyod, aparèy chofaj, ak lòt aparèy elektwonik oswa semi-conducteurs. Nou pral pran angajman pou bay itilizatè yo bon jan kalite, pwodwi efikas ak sèvis atansyon.

Li aksepte peman atravè kat kredi, T/T, West Union, ak Paypal. PDDN pral voye machandiz yo bay kliyan lòt bò dlo atravè FedEx, DHL, pa lanmè, oswa pa lè. If you want high-quality 808nm diode laser bars for module stack, tanpri voye nou kesyon; nou pral la pou ede w.

Metòd Peman

L/C, T/T, Western Union, Paypal, Kat kredi elatriye.

chajman

Pa lanmè, pa lè, pa eksprime, jan kliyan mande.

Kondisyon Depo

1) Sere nan yon anviwònman sèk nan tanperati chanm.

2) Evite tanperati imid ak wo.

3) Sèvi ak imedyatman apre ouvèti sak anbalaj anndan an.

5 FAQs of 808nm diode laser bars for module stack

Here are five common questions about 808nm diode laser bars for module stacks:

What makes 808nm diode laser bars suitable for module stacks?

808nm light is strongly absorbed by materials like Nd:YAG. This makes pumping solid-state lasers efficient. The wavelength is reliable for industrial use. Diode laser bars offer high power density. Stacking them creates very powerful modules.

How long do these 808nm laser bars typically last?

Lifetime depends heavily on operating conditions. Proper cooling is critical. Drive current levels matter. Stable electrical supply helps. Under recommended conditions, expect thousands of hours. Exceeding specs shortens life significantly.

What power levels can one 808nm laser bar achieve?

Single bars deliver high power. Outputs range from tens to hundreds of watts. Exact power depends on the bar design. Cooling efficiency limits maximum power. Stacking multiple bars multiplies the total output power substantially.

Why is thermal management so important for stacked modules?

Diode laser bars generate substantial heat. Heat degrades performance. Too much heat shortens the bar’s life. Thermal lensing can ruin beam quality. Effective cooling maintains stability. It ensures consistent power output. Good heat sinks and coolers are essential.

What key specifications should I check when selecting bars for stacking?

Verify the wavelength accuracy. Ensure the spectral width is narrow. Check the output power per bar. Confirm the operating current and voltage. Examine the fast-axis divergence angle. Assess the fill factor. Look at the cooling requirements. Compatibility with the stack holder is necessary.

(808nm diode laser bars for module stack)

DEMANDE YON PREVO

PWODWI ki gen rapò

100% new original stock SKB33-08 33A800V Full Series Rectifier diode module

1200V 100A FRD Full Bridge Diode Module Low Forward Voltage 2.0V With Built-in Full Bridge FRD Construction For Power Converters

XL74610 Ideal Diode Module Adopts LM74610 Dedicated Chip to Simulate Simulation Ideal Diode Rectifier Board 1.5V-36V 0mA 15A/30A

DIODE RECTIFIER MODULE DD89N12K DD89N14K DD89N16K DD89N18K

AK1E-430C TVs Diode 625V 1000A (1kA) (8/20us)