Tiristè sou entènèt | Semi-kondiktè pouvwa-wo kalite

PARAMÈT PWODWI

Deskripsyon

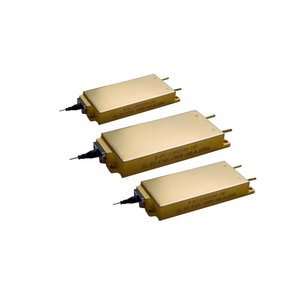

Apèsi sou (B6C)2 Seri Asanble yo

(B6C)2 Asanble seri yo fèt pou bay pèfòmans siperyè nan anviwònman kote presizyon, dirab, ak efikasite yo esansyèl. Yo fèt pou satisfè nòm endistri ki sevè epi yo ka adapte yo ak kondisyon aplikasyon espesifik yo. Seri a li te ye pou entegre fonksyonalite konplèks nan desen kontra enfòmèl ant, diminye anprint an jeneral pandan y ap amelyore kapasite operasyonèl yo.

Asanble sa yo ka gen ladan sikui entegre, detèktè, actuators, konektè, ak lòt eleman elektwonik oswa mekanik ki travay ansanm san pwoblèm. Filozofi konsepsyon dèyè (B6C)2 Seri mete aksan sou modilarite, pèmèt amelyorasyon fasil ak antretyen san yo pa konpwomèt sou pèfòmans.

Karakteristik nan (B6C)2 Seri Asanble yo

Segondè Precision: Manifaktire ak tolerans sere asire operasyon egzat nan kondisyon mande.

Konsepsyon kontra enfòmèl ant: Entegre eleman miltip nan yon pake rasyonalize, ekonomize espas ak pwa.

Dirab ak fyab: Bati pou kenbe tèt ak anviwònman piman bouk epi ofri pèfòmans ki estab alontèm.

Fonksyonalite entegre: Konbine plizyè fonksyon nan yon sèl asanble, diminye konpleksite ak amelyore efikasite.

Opsyon Customizable: Èske yo ka Customized anfòm bezwen aplikasyon espesifik, ki gen ladan seleksyon materyèl, konfigirasyon, ak paramèt pèfòmans.

Fasilite enstalasyon: Ki fèt pou entegrasyon senp nan sistèm ki egziste deja, souvan prezante kapasite plug-and-play.

Materyèl avanse: Itilize materyèl dènye kri pou karakteristik pèfòmans amelyore tankou rezistans chalè, rezistans korozyon, ak fòs.

Konfòmite ak Nòm yo: Konfòme ak estanda enpòtan entènasyonal ak endistri espesifik pou sekirite ak pèfòmans.

Modilè konsepsyon: Fasilite amelyorasyon fasil ak antretyen, ak eleman ki ka ranplase oswa mete ajou endividyèlman.

Optimizasyon pèfòmans: Optimize pou efikasite enèji ak pèfòmans, kontribiye nan redwi depans operasyon yo sou tan.

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

Specification of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

High-standard industrial electrical wire ports, multicore ports, cords, cords, and wire assemblies are crafted to provide robust efficiency sought after atmospheres. These parts are crafted from premium materials, consisting of high-grade thermoplastics, steels, and corrosion-resistant alloys, ensuring longevity under severe conditions. The connectors feature a temperature level resistance series of -40 ° C pou 120 °C, making them suitable for both indoor and outdoor applications. With IP67/IP68 access protection rankings, they are dustproof, water resistant, and immune to moisture, oils, and chemicals, ideal for rough commercial setups.

Electrically, these adapters support voltages approximately 1000V and existing scores of 30A per call, with reduced contact resistance (

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

Applications of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

High typical commercial electric cable connectors, multicore connectors, wires, cable televisions, and cable television settings up are critical components in contemporary industrial and commercial systems, ensuring reliable connectivity, sikilasyon pouvwa, and signal transmission across requiring environments. These products are crafted to fulfill rigorous efficiency requirements, offering resilience, security, and resistance to severe conditions such as heats, dampness, resonances, and chemical exposure. Their applications span varied industries, making it possible for seamless operations in complicated arrangements.

In production and automation, these adapters and cables are integral to equipment, robotik, and control systems. They promote specific signal transmission for sensing units, actuators, and programmable reasoning controllers (PLC yo), making certain efficient assembly line. Multicore adapters streamline circuitry in compact spaces, lowering setup time while keeping robust links. Heavy-duty cable assemblies are utilized in electric motor drives, sistèm transporteur, and CNC equipments, where high current capability and abrasion resistance are essential.

The power industry counts on these elements for renewable resource systems, such as solar ranches and wind turbines, where weatherproof ports and UV-resistant cable televisions guarantee long life. In oil and gas, explosion-proof adapters and armored cables avoid dangers in unstable environments. Power distribution networks make use of high-voltage cable television settings up to maintain grid security.

Transport sectors, including automotive, aerospace, and trains, rely on these services for engine control devices, avionics, and signaling systems. Heat-resistant and light-weight cords improve fuel efficiency and safety and security. Electric cars (EVs) utilize high-current connectors for battery administration and charging framework.

Telecom facilities uses multicore adapters and secured cable televisions to sustain high-speed information transmission in information centers and 5G networks. Medical devices utilizes sterilizable, high-precision adapters and wires for imaging systems, individual monitors, and surgical tools, guaranteeing conformity with rigorous hygiene standards.

In building and construction and facilities, these parts power clever buildings, a/c systems, and lights controls. Personalized cord assemblies adapt to unique task requirements, from underground electrical wiring to smart city applications.

Generally, high-standard commercial ports and cable televisions are necessary for modern innovation, using scalability, conformity with international certifications (e.g., UL, IEC), and flexibility to advancing market demands. Their function in improving operational performance, safety and security, and connectivity makes them vital across international markets.

Konpayi Profile

Luoyang Datang enèji teknoloji Co.Ltd(sales@pddn.com) se youn nan antrepwiz dirijan yo nan teknoloji elektwonik pouvwa ak pwodwi pouvwa, ki se konplètman patisipe nan devlope varyateur solè, transfòmatè, regilatè vòltaj, kabinèt distribisyon, tiristor, modil yo, dyod, aparèy chofaj, ak lòt aparèy elektwonik oswa semi-conducteurs. Nou pral pran angajman pou bay itilizatè yo bon jan kalite, pwodwi efikas ak sèvis atansyon.

Li aksepte peman atravè kat kredi, T/T, West Union, ak Paypal. PDDN pral voye machandiz yo bay kliyan lòt bò dlo atravè FedEx, DHL, pa lanmè, oswa pa lè. If you want high-quality High standard industrial electrical wire connector multicore connector wires cables & cable assemblies, tanpri voye nou kesyon; nou pral la pou ede w.

Metòd Peman

L/C, T/T, Western Union, Paypal, Kat kredi elatriye.

chajman

Pa lanmè, pa lè, pa eksprime, jan kliyan mande.

Kondisyon Depo

1) Sere nan yon anviwònman sèk nan tanperati chanm.

2) Evite tanperati imid ak wo.

3) Sèvi ak imedyatman apre ouvèti sak anbalaj anndan an.

5 FAQs of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

What are the primary applications of high-standard industrial multicore connectors and cable assemblies? High-standard industrial multicore connectors and cable assemblies are designed for demanding environments such as manufacturing plants, automation systems, energy infrastructure, ak machin lou. They ensure reliable power and signal transmission in harsh conditions, including exposure to extreme temperatures, imidite, pwodwi chimik yo, ak vibrasyon. Common uses include connecting control panels, motè, detèktè, ak robotik, where durability and precision are critical.

What materials are used in these connectors to ensure durability? These connectors are constructed from high-grade thermoplastics, metals, and engineered composites to withstand industrial stressors. Housing materials like polyamide or stainless steel offer resistance to corrosion, UV radiation, and impact. Internally, contacts are often gold-plated or tin-coated for optimal conductivity and oxidation resistance. Cable jackets use PVC, PUR, or TPE blends to protect against abrasion, oils, and temperature fluctuations, ensuring long-term performance.

What voltage and temperature ratings do these connectors support? Industrial multicore connectors typically handle voltages up to 1000V AC/DC, with current ratings ranging from 5A to 250A, depending on the design. Temperature tolerance ranges from -40°C to +120°C, making them suitable for both freezing environments and high-heat applications like near engines or industrial ovens. Always verify the product’s specifications to match your operational requirements.

Can these connectors be customized for specific industrial needs? Wi, customization is common. Manufacturers offer tailored solutions for wire gauge, core count (2 pou 50+ cores), length, pwoteksyon (braided or foil for EMI/RFI protection), and connector types (M12, M16, DIN, elatriye.). Colors, markings, and IP ratings (e.g., IP67/IP68 for waterproofing) can also be adjusted to meet industry standards or project-specific demands.

How do I ensure proper installation and maintenance? Use crimping or soldering tools recommended by the manufacturer for secure terminations. Follow torque specifications when tightening screws to avoid damage. Regularly inspect connectors for wear, corrosion, or loose connections, and clean them with non-abrasive solvents. For cable assemblies, avoid sharp bends and ensure strain relief is properly secured. Adhering to these practices minimizes downtime and extends product lifespan.

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

DEMANDE YON PREVO

PWODWI ki gen rapò

For BMW’s new 2 Series F44 front bumper assembly with radiator and headlights

Auto Engine Assembly 1.8T CJE R4 Complete Engine For Audi A4 B8 A5 8T

Pinch Roller Assembly Paper Feed Assy For Myjet Human Infiniti Konica Inkjet Printer Press Roller Set

High Quality New N54B30 Auto Engine Assembly N52 N54 N55 for BMW 740 335 X6

3.0L V6 N52 N52B30 Engine For BMW OEM 11002318498 N52B30 Engine Assembly