Tiristori Online | Energetski poluvodiči visoke kvalitete

PARAMETRI PROIZVODA

Opis

Pregled visokofrekventnih tiristora

Visokofrekventni tiristori su specijalizirani poluvodički uređaji dizajnirani za rad na višim frekvencijama od konvencionalnih tiristora. Koriste se u aplikacijama koje zahtijevaju brzo prebacivanje, kao što je visokofrekventno grijanje, upravljanje motorom, i napajanja. Ovi uređaji mogu podnijeti značajnu električnu energiju dok istovremeno pružaju učinkovitu i pouzdanu izvedbu prebacivanja na frekvencijama koje se protežu izvan tipičnog radnog raspona standardnih tiristora.

Značajke visokofrekventnih tiristora

Velika brzina prebacivanja: Sposoban za rad na puno višim frekvencijama u usporedbi s tradicionalnim tiristorima, što ih čini prikladnima za aplikacije s brzim prebacivanjem.

Učinkovito rukovanje snagom: Dizajniran za upravljanje značajnom električnom energijom uz minimalne gubitke tijekom sklopnih operacija.

Niska struja okidanja vrata: Potrebna je manja struja da bi se pokrenula radnja prebacivanja, povećanje učinkovitosti i smanjenje proizvodnje topline.

Robusna konstrukcija: Napravljen da izdrži teške uvjete i toplinski stres, osiguravajući pouzdan rad tijekom vremena.

Kompaktna veličina: Nudi manji otisak u usporedbi s nižim frekvencijama, što je korisno za kompaktne dizajne.

Poboljšana dv/dt sposobnost: Poboljšana sposobnost rukovanja brzim promjenama napona bez lažnog uključivanja, pridonoseći stabilnijem radu.

Smanjeni EMI: Niže elektromagnetske smetnje zahvaljujući optimiziranom dizajnu, što je ključno za osjetljive aplikacije.

Svestrane primjene: Prikladno za širok raspon industrija uključujući automobilsku, industrijska automatizacija, telekomunikacija, i sustavi obnovljivih izvora energije.

(Mala visokofrekventna peć za taljenje za lijevanje metalnog otpada Čelik Bakar Al Zlato Mini peć)

Specification of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

This compact high-frequency melting furnace is constructed for performance. It thaws scrap steel quickly. You can refine steel, copper, light weight aluminum, also gold. The small size fits easily in workshops. It does not require much space. The furnace makes use of high-frequency induction home heating. This approach is very reliable. It heats steel directly inside the crucible. Energy loss is minimal. You conserve power. Thawing occurs promptly. You see results in mins, not hours.

Capacity alternatives are practical. Typical sizes hold 1kg to 5kg of metal. Pick the dimension matching your requirements. The crucible is solid. It takes care of high temperatures well. Substitute is straightforward. Operation is straightforward. Controls are basic. Establish the temperature. Establish the timer. The heating system does the work. Digital presents reveal the present condition clearly. You see the temperature level. You see the time remaining. Security is essential. The device includes get too hot security. It closes down immediately if needed. The housing remains awesome throughout operation. You stay clear of burns. The furnace is reputable for day-to-day usage.

Maintenance is very easy. Keep the device tidy. Check the links regularly. The layout is robust. It withstands workshop problems. This furnace is suitable for little shops. Jewelers use it for precious metals. Hobbyists cast detailed parts. Colleges use it for demos. It thaws metal cleanly. Slag formation is minimized. You obtain top quality molten steel. The financial investment pays off quickly. Manufacturing prices drop. This device enhances your metalworking capability dramatically.

(Mala visokofrekventna peć za taljenje za lijevanje metalnog otpada Čelik Bakar Al Zlato Mini peć)

Applications of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

These compact high-frequency melting heaters change exactly how tiny workshops take care of steel. They thaw scrap quickly and successfully. Forget cumbersome traditional tools. These mini heating systems use electromagnetic induction. Warm develops inside the metal itself. This technique is extremely quick. You get molten metal ready in minutes, not hours. It saves significant energy and time.

Work with many metals. Thaw scrap steel successfully. Manage copper and brass alloys conveniently. Light weight aluminum scrap thaws perfectly too. Rare-earth elements like silver and gold are no problem. The specific temperature control is essential. You set the exact warm required. This makes certain tidy melts each time. You obtain regular outcomes batch after batch.

These heating systems are excellent for tiny shops. Jewelers enjoy them for casting great items. Hobbyists locate them ideal for home jobs. Educational laboratories utilize them for presentations. They fit conveniently on a durable bench. Their little impact saves valuable shop space. Procedure is straightforward. Load your scrap steel right into the crucible. Select your program or set the temperature level. After that start the melting cycle. The heating system does the rest.

Rate is a major benefit. Induction home heating is direct and powerful. There’s no slow-moving pre-heating stage. You go from solid scrap to putting liquid steel quickly. Temperature level precision is excellent. This prevents burning delicate alloys. It likewise makes sure the ideal melt for excellent casting flow. Control the process specifically. This brings about higher quality castings and much less waste.

Energy efficiency issues. Induction technology focuses warm directly on the metal charge. Much less warmth runs away into the air. This lowers your electricity expenses. The process is likewise cleaner general. You handle much less oxidation loss. Your beneficial metal stays in the crucible. Crucible selections are essential. Use graphite crucibles for brass or copper. Usage ceramic crucibles for aluminum. Suit the crucible to your metal for best results. These heaters offer real power and precision in a little plan.

Profil tvrtke

PDDN Photoelectron Technology Co., doo(prodaja@pddn.com) jedno je od vodećih poduzeća u tehnologiji energetske elektronike i energetskih proizvoda, koja je u potpunosti uključena u razvoj solarnih pretvarača, transformatori, regulatori napona, razvodni ormari, tiristori, moduli, diode, grijalice, i druge elektroničke uređaje ili poluvodiče. Bit ćemo posvećeni pružanju korisnicima visoke kvalitete, učinkoviti proizvodi i pažljiva usluga.

Prihvaća plaćanje putem kreditne kartice, T/T, West Union, i Paypal. PDDN će robu slati kupcima u inozemstvo putem FedExa, DHL, morem, ili zrakom. If you want high-quality Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace, pošaljite nam upite; mi ćemo biti ovdje da vam pomognemo.

Načini plaćanja

L/C, T/T, Western Union, Paypal, Kreditna kartica itd.

otprema

Po moru, zračnim putem, ekspresno, prema zahtjevima kupaca.

Uvjeti skladištenja

1) Čuvati u suhom okruženju na sobnoj temperaturi.

2) Izbjegavajte vlagu i visoke temperature.

3) Upotrijebite odmah nakon otvaranja unutarnje vrećice za pakiranje.

5 FAQs of Small High Frequency Melting Furnace for Casting Scrap Metal Steel Copper Al Gold Mini Furnace

Small High Frequency Melting Furnace FAQs

What metals can this small furnace melt?

This furnace melts scrap metal. It handles steel, copper, aluminum, and even gold. Different metals need different melting temperatures. The furnace reaches high heat levels fast. This makes it versatile for various projects.

How much metal can it melt at once?

Capacity depends on the crucible size. Crucibles hold the molten metal. Common sizes are 1kg, 2kg, and 3kg. Choose the crucible based on your project needs. The furnace body itself is small. It fits easily in workshops or garages.

What crucible should I use?

Use graphite or ceramic crucibles. The right crucible depends on the metal you melt. Graphite works well for copper and aluminum. Ceramic is better for steel. Match the crucible to the metal type and temperature. Crucibles wear out over time. Replace them when they crack or thin.

What power supply does it need?

This furnace uses standard electricity. It typically needs 220V power. Check the specific model’s voltage requirements. High frequency melting is efficient. It heats metal quickly with less energy waste. Ensure your workshop has the correct power outlet.

Does it need water cooling?

Da, water cooling is essential. The furnace generates intense heat. Water flows through the coil to prevent overheating. Never run the furnace without the water cooling system connected. This protects the equipment. Use clean water and check the flow regularly.

(Mala visokofrekventna peć za taljenje za lijevanje metalnog otpada Čelik Bakar Al Zlato Mini peć)

ZATRAŽITE PONUDU

POVEZANI PROIZVODI

JYM-II network power supply high frequency charging rectifier module

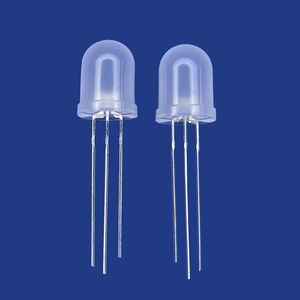

tiristor I priborixys visokofrekventni tiristor MCC21-12i01B

Transformer 220v to 12v single phase transformer high frequency power transformer

Other Electrical Equipment Hot Thyristor Scr ERG51-09 High Frequency Thyristor

Industrial Controls High Frequency Thyristor SW50CXC15C Scr Thyristor