Thyristors Online | Nā Semiconductors Mana Kiʻekiʻe

NA PALAPALA HUA

wehewehe

ʻO ka nānā ʻana o nā Thyristors kiʻekiʻe

ʻO High Frequency Thyristors he mau mea semiconductor kūikawā i hoʻolālā ʻia e hana i nā alapine kiʻekiʻe ma mua o nā thyristors maʻamau.. Hoʻohana ʻia lākou i nā noi e koi ana i ka hoʻololi wikiwiki, e like me ka hoʻomehana alapine kiʻekiʻe, mana kaʻa, a me nā lako mana. Hiki i kēia mau mea hana ke mālama i ka mana uila nui aʻo ka hāʻawi ʻana i ka hana hoʻololi kūpono a hilinaʻi hoʻi i nā alapine e ʻoi aku ma mua o ka pae hana maʻamau o nā thyristors maʻamau..

Nā hiʻohiʻona o nā Thyristors High Frequency

Kiʻekiʻe hoʻololi wikiwiki: Hiki ke hana i nā alapine kiʻekiʻe loa i hoʻohālikelike ʻia me nā thyristors kuʻuna, e hoʻolilo iā lākou i kūpono no nā noi hoʻololi wikiwiki.

ʻO ka lawelawe mana kūpono: Hoʻolālā ʻia e hoʻokele i ka mana uila nui me nā poho liʻiliʻi i ka wā o ka hoʻololi ʻana.

ʻO ka puka haʻahaʻa o kēia manawa: E koi i ka liʻiliʻi o kēia manawa e hoʻomaka i ka hana hoʻololi, hoʻonui i ka pono a me ka ho'ēmiʻana i ka hana wela.

Hana ʻino: Hana ʻia e kū i nā kaiapuni ʻino a me ke kaumaha wela, hōʻoia i ka hana hilinaʻi i ka manawa.

Nui Paʻi: Hāʻawi i kahi kapuaʻi liʻiliʻi i hoʻohālikelike ʻia me nā hoa hana haʻahaʻa, he mea maikaʻi ia no nā hoʻolālā paʻa.

Hoʻonui ʻia ka mana dv/dt: Hoʻonui i ka hiki ke mālama i nā hoʻololi uila wikiwiki me ka ʻole o ka hoʻohuli ʻana, hāʻawi i ka hana paʻa.

EMI hoemi: Haʻahaʻa electromagnetic interference ma muli o ka optimized hoʻolālā, he mea koʻikoʻi ia no nā noi koʻikoʻi.

Nā mea hoʻohana like ʻole: He kūpono no ka nui o nā ʻoihana me ka automotive, ʻoihana ʻenehana, kelepona, a me nā ʻōnaehana ikehu hou.

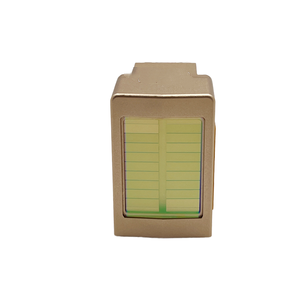

(High Frequency Power Thyristor KG100A Inverter)

Specification of High Frequency Power Thyristor KG100A Inverter

The High Frequency Power Thyristor KG100A Inverter is built for demanding industrial applications requiring precise power control. It operates efficiently in high-frequency environments, making it ideal for systems like induction heating, melting, and welding. The device handles voltages up to 1600V and currents up to 100A, ensuring reliable performance under heavy loads. Its advanced design minimizes energy loss, improving overall system efficiency.

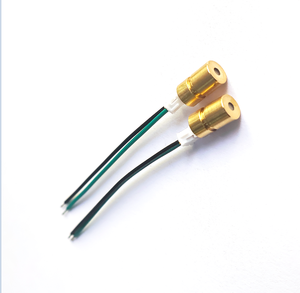

The thyristor’s structure uses a pressure-assisted contact system. This design enhances thermal stability and current distribution. A gold-plated molybdenum layer on the gate ensures low trigger voltage and consistent switching. The ceramic housing provides strong insulation and heat resistance. Cooling is managed through a liquid or forced-air system, maintaining safe operating temperatures even during extended use.

Switching speed is a key feature. The KG100A achieves turn-off times below 15 microseconds, reducing downtime in high-speed cycles. Dynamic voltage sharing across series-connected units prevents overloads. This balance extends component lifespan and system reliability. Built-in protection circuits guard against overcurrent, overvoltage, and overheating. Failures are less likely, reducing maintenance needs.

Compatibility with existing industrial setups simplifies integration. Standard mounting interfaces and control signals work with most automation systems. Custom configurations are available for specific voltage or frequency requirements. Technical support includes on-site troubleshooting and performance optimization.

Durability is tested under extreme conditions. The thyristor withstands temperatures from -40°C to 125°C and vibrations up to 5g. A sealed housing protects against dust, mākū, and chemical exposure. Rigorous quality checks ensure compliance with international safety standards.

Applications span metal processing, semiconductor manufacturing, a me nā ʻōnaehana ikehu hou. Users report reduced energy costs and improved process consistency. Replacement parts and upgrade kits are accessible globally. Training programs help operators maximize equipment potential.

The KG100A suits both new installations and retrofits. Its compact size saves space in crowded control panels. Real-time monitoring via compatible software allows predictive maintenance. Hoʻemi ʻia ka manawa hoʻomaha, boosting productivity.

(High Frequency Power Thyristor KG100A Inverter)

Applications of High Frequency Power Thyristor KG100A Inverter

The KG100A High Frequency Power Thyristor Inverter serves as a reliable solution for industrial power control. It handles high-frequency switching efficiently. This makes it suitable for applications requiring precise energy management. The device uses advanced thyristor technology. This ensures stable performance under heavy loads. Industries like metal processing and manufacturing benefit from its capabilities. It supports induction heating systems. These systems melt or shape metals quickly. The inverter adjusts power output accurately. This maintains consistent temperatures during operations.

Renewable energy systems also use the KG100A. It integrates with solar or wind power setups. The inverter converts DC to high-frequency AC effectively. This improves energy transfer efficiency. Its design reduces power loss during conversion. Users save on operational costs over time. The device operates within a wide input voltage range. It works with 200V to 600V power sources. Output frequencies reach up to 100 kHz. This flexibility suits diverse industrial needs.

The KG100A includes built-in protection mechanisms. It guards against overloads and short circuits. Automatic shutdown prevents damage during faults. Heat dissipation features keep temperatures stable. This extends the equipment’s lifespan. Maintenance requirements stay low. The compact design saves space in installations. It withstands harsh environments like high humidity or dust.

Manufacturers prioritize safety with this inverter. Insulated components reduce electrical risks. Compliance with international standards ensures reliability. Operators control settings via a user-friendly interface. Real-time monitoring tracks performance metrics. This allows quick adjustments during tasks. Energy efficiency meets modern environmental regulations. Businesses cut carbon footprints while maintaining productivity.

The KG100A outperforms traditional inverters in speed and precision. Thyristor-based switching responds faster than mechanical systems. This reduces lag in power adjustments. Industrial processes achieve higher output quality. Downtime decreases due to robust construction. Companies see improved ROI through consistent operation. The inverter adapts to evolving technological demands. It remains a practical choice for upgrading power systems.

ʻO ka moʻolelo o ka hui

PDDN Photoelectron Technology Co., Ltd.(kuai@pddn.com) ʻo ia kekahi o nā ʻoihana alakaʻi i ka ʻenehana uila uila a me nā huahana mana, i komo piha i ka hoʻomohala ʻana i nā mea hoʻohuli lā, nā mea hoʻololi, nā mea hoʻoponopono uila, nā keʻena hoʻolaha, kouristors, modules, diodes, nā mea hoʻomehana, a me nā mea uila ʻē aʻe a i ʻole semiconductor. E paʻa mākou i ka hāʻawi ʻana i nā mea hoʻohana me ke kūlana kiʻekiʻe, huahana pono a me ka lawelawe noonoo.

ʻAe ia i ka uku ma o Kāleka Kāleka, T/T, Hui Komohana, a me Paypal. E hoʻouna aku ʻo PDDN i nā waiwai i nā mea kūʻai aku ma waho ma o FedEx, DHL, ma ke kai, a ma ka lewa paha. If you want high-quality High Frequency Power Thyristor KG100A Inverter, e ʻoluʻolu e hoʻouna mai iā mākou i nā nīnau; eia mākou e kōkua iā ʻoe.

Uku Uku

L/C, T/T, Hui Komohana, Paypal, Kāleka ʻaiʻē etc.

Hoʻouna

Ma ke kai, ma ka lewa, ma ka hoike, e like me ke noi a nā mea kūʻai aku.

Nā Kūlana Waihona

1) E mālama i loko o kahi maloʻo ma kahi mahana wela.

2) E pale i ka pulu a me ka wela wela.

3) E hoʻohana koke ma hope o ka wehe ʻana i ka ʻeke ʻeke i loko.

5 FAQs of High Frequency Power Thyristor KG100A Inverter

What is the KG100A High Frequency Power Thyristor Inverter used for?

The KG100A inverter converts direct current (DC) into high-frequency alternating current (AC). It powers industrial equipment like induction heaters, melting furnaces, and high-frequency welding machines. The design handles heavy loads and ensures stable performance in demanding environments.

How efficient is the KG100A compared to standard inverters?

The KG100A operates at over 95% efficiency under full load. Advanced thyristor technology reduces energy loss during power conversion. This cuts electricity costs and minimizes heat generation. Standard inverters typically achieve 85-90% pono.

Does the KG100A require special cooling systems?

ʻAe. The inverter uses forced air or water cooling to manage heat during high-power operations. Proper cooling prevents overheating and extends component lifespan. Users must ensure cooling systems match the inverter’s workload requirements.

What safety features protect the KG100A from damage?

Built-in safeguards include overvoltage protection, overcurrent shutdown, and short-circuit detection. These features prevent electrical surges and component failure. Regular maintenance checks ensure safety systems function correctly.

Can the KG100A work with existing industrial power setups?

ʻAe. The inverter integrates with standard 3-phase AC power supplies (380V-480V). Compatibility with most industrial control systems simplifies installation. Users should verify voltage ratings and load capacity before connecting to avoid mismatches.

(High Frequency Power Thyristor KG100A Inverter)

NOI I KA PALAPALA

NA HUAKAI PILI

R48-2000E3 network power supply high frequency charging rectifier module

hou kumu alapine kiʻekiʻe maoli mana kiʻekiʻe thyristor SCR module Y50KAD08-14 KA800A1400V 800A1600V

ʻO Thyristor Module kiʻekiʻe alapine thyristor IRKT91/12 1200V Rectifier Diodes SCR 98%

ICZX MRFX1K80H High Frequency Rf Power Transistors MRFX 1K80H MRFX1K80H

Power switching high frequency rectifier diode gate power GE SCR 10710-021-W alternator rectifier diode