Thyristors Online | Semiconductors mai inganci mai ƙarfi

KYAUTA KYAUTA

Bayani

Bayani na Rectifier Diodes

Diodes masu gyara su ne na'urorin semiconductor da aka yi amfani da su da farko don canza canjin halin yanzu (AC) zuwa kai tsaye halin yanzu (DC). Suna ba da damar halin yanzu don gudana cikin sauƙi ta hanya ɗaya yayin da suke toshe shi a kishiyar hanya. Wannan kadara ta unidirection tana sanya su mahimman abubuwan haɗin gwiwa a cikin kayan wuta, sarrafa sigina, da na'urorin lantarki daban-daban. Rectifier diodes na iya ɗaukar igiyoyi masu yawa da ƙarfin lantarki, sanya su m ga yawa aikace-aikace.

Siffofin Diodes Rectifier

Haɗin kai Unidirectional: Yana sauƙaƙe kwararar halin yanzu ta hanya ɗaya kawai, yadda ya kamata toshe baya halin yanzu.

Babban Gudanarwa na Yanzu: An ƙirƙira don ɗaukar kwararan igiyoyi na gaba, dace da babban iko aikace-aikace.

Kololuwar Inverse Voltage (PIV): Zai iya jure babban juyi ƙarfin lantarki ba tare da karyewa ba.

Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfafawa: Yana rage asarar kuzari azaman zafi, inganta inganci.

Lokacin farfadowa da sauri: Canzawa da sauri daga gudanarwa zuwa jihohin da ba sa gudanarwa, m ga high-mita aikace-aikace.

Zaman Lafiya: Yana kiyaye aiki a cikin kewayon zafin jiki mai faɗi, tabbatar da aminci a yanayi daban-daban.

Karamin Girman: Ƙananan nau'i na nau'i yana sauƙaƙe haɗin kai cikin ƙananan ƙirar lantarki.

Mai Tasiri: Yana ba da mafita na tattalin arziki don buƙatun canza AC-zuwa-DC.

Daban-daban na Fakiti: Akwai a cikin zaɓuɓɓukan marufi da yawa don dacewa da buƙatun hawa daban-daban.

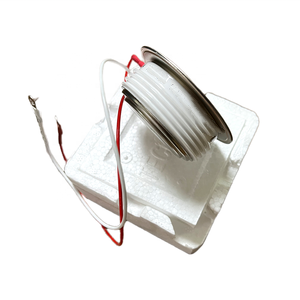

(rectifier ga electroplating,Mai gyara gada diode kashi uku)

Specification of rectifier for electroplating,Mai gyara gada diode kashi uku

This three-phase diode bridge rectifier gives steady DC power for electroplating work. It manages difficult industrial problems well. It changes three-phase a/c power into smooth DC power. This DC power is vital for putting steel coatings onto components.

The rectifier accepts standard three-phase air conditioning input voltage. Common levels are 380V or 415V A/C. Outcome DC voltage changes within a wide range. Normal arrays are 0-12V or 0-24V DC. Outcome DC current is high. Options consist of 1000A, 2000A, 3000A, even greater. Specific specifications match your plating tank size and procedure requirements.

Effective diodes develop the core bridge circuit. These diodes take care of the high existing circulation efficiently. They create heat. Air air conditioning or water cooling removes this warm. Air-cooled systems use huge followers. Water-cooled kinds require a cooling water. Water air conditioning deals with bigger loads better.

Control is straightforward and reputable. Hand-operated handles or electronic panels established the output voltage and present. Operators adjust these for the particular plating task. Meters show the actual DC voltage and existing outcome. This lets you monitor efficiency frequently.

Safety is built-in. Over-current defense journeys if lots surpasses secure restrictions. Over-temperature protection shuts things down if cooling stops working. Short-circuit security defend against unintentional mistakes. These attributes safeguard both the rectifier and your plating arrangement.

The system sits in a strong steel enclosure. This protects the internal components. Terminals are big and sturdy. They attach thick DC busbars to the plating container anodes and cathodes. Input utilizes basic AC cable access. The layout focuses on easy access for maintenance.

(rectifier ga electroplating,Mai gyara gada diode kashi uku)

Applications of rectifier for electroplating,Mai gyara gada diode kashi uku

Electroplating demands DC power. Air conditioner power comes from the grid. Rectifiers transform a/c to DC. They are essential for electroplating. The 3 stage diode bridge rectifier is a common option. It deals with commercial power requires well. This rectifier uses 6 diodes. They attach in a bridge pattern. Three air conditioning input stages feed into it. The diodes guide the present flow. They just enable existing in one direction. This action converts all 3 air conditioning stages into DC result.

This DC power feeds the electroplating bath. The metal ions relocate in the direction of the workpiece. They deposit onto its surface area. A steady DC supply is crucial. It controls the plating density. It regulates the plating top quality. The 3 stage diode bridge offers benefits. Its result surge is less than single-phase kinds. Smoother DC suggests far better plating results. It utilizes the input power effectively. Less energy is lost as warm. This saves money on power. These rectifiers are really robust. Diodes are straightforward and trustworthy parts. They manage high currents easily. Bukatun kula ba su da yawa. An rage raguwar lokaci.

Industrial electroplating lines require high power. 3 phase systems give this power effectively. The bridge rectifier scales well. It matches large plating storage tanks. It matches high-speed plating procedures. Voltage and present control are crucial. Modern rectifiers include adjustable controls. Operators set the voltage specifically. They set the existing density specifically. This makes certain regular layering quality set after set. Air conditioning is important for hefty loads. Air cooling down usually is sufficient. Water cooling manages extreme task cycles. Rectifiers are developed tough for factory atmospheres. They stand up to dirt and chemicals. Trustworthy DC power is the foundation of excellent electroplating.

Bayanan Kamfanin

Abubuwan da aka bayar na PDDN Photoelectron Technology Co., Ltd., Ltd.(sales@pddn.com) yana daya daga cikin manyan kamfanoni a fasahar samar da wutar lantarki da kuma samar da wutar lantarki, wanda ke da hannu sosai wajen haɓaka injin inverters na hasken rana, masu aikin wuta, masu sarrafa wutar lantarki, ɗakunan ajiya na rarrabawa, thyristors, kayayyaki, diodes, masu dumama, da sauran na'urorin lantarki ko semiconductors. Za mu himmatu wajen samarwa masu amfani da inganci mai inganci, samfurori masu inganci da sabis na kulawa.

Yana karɓar biyan kuɗi ta Katin Kiredit, T/T, West Union, da Paypal. PDDN za ta jigilar kayayyaki zuwa abokan ciniki a ƙasashen waje ta hanyar FedEx, Farashin DHL, ta teku, ko ta iska. If you want high-quality rectifier for electroplating,Mai gyara gada diode kashi uku, don Allah a aiko mana da tambayoyi; za mu kasance a nan don taimaka muku.

Hanyoyin Biyan Kuɗi

L/C, T/T, Western Union, Paypal, Katin Kiredit da dai sauransu.

Jirgin ruwa

Ta teku, ta iska, ta hanyar bayyanawa, kamar yadda abokan ciniki suka nema.

Yanayin Ajiya

1) Ajiye a cikin busasshiyar wuri a zazzabi na ɗaki.

2) Ka guji damshi da zafin jiki mai yawa.

3) Yi amfani nan da nan bayan buɗe jakar tattarawa na ciki.

5 FAQs of rectifier for electroplating,Mai gyara gada diode kashi uku

Here are five key questions about three-phase diode bridge rectifiers for electroplating:

What makes a three-phase rectifier better than single-phase for electroplating? Three-phase rectifiers handle much more power efficiently. They deliver smoother DC output voltage. This smoother power means better quality plating. You get more consistent metal deposition. Single-phase units struggle with high-power jobs.

How does the diode bridge actually work? It uses six diodes. These diodes are arranged in a specific bridge circuit. They let current flow in only one direction. Alternating current (AC) comes in from the three power lines. The diodes switch the current path constantly. Direct current (DC) comes out. This DC powers the plating tank.

How much power can these rectifiers handle? They are built for tough industrial jobs. Standard units manage from a few hundred amps up to many thousands of amps. Output voltages typically range between 12 kuma 24 volts DC. You pick the size based on your plating tank size. Match the rectifier to your specific plating current needs.

Why is low ripple voltage important? Ripple is the small leftover AC variation in the DC output. High ripple is bad. It causes uneven plating. You might get rough deposits or burnt spots on parts. Three-phase diode bridges naturally have lower ripple. This gives you cleaner, more uniform plating results.

Do these rectifiers need special cooling? Ee, kwata-kwata. Passing huge currents creates significant heat. This heat must be removed. Most industrial units use either forced air cooling with big fans or water cooling. Proper cooling prevents damage. It ensures the rectifier runs reliably for years. Always check the cooling system works.

(rectifier ga electroplating,Mai gyara gada diode kashi uku)

NEMI TSOKACI

KAYAN DA AKA SAMU

ZONCN Three Phase Standard PA025G120W1 Diode Bridges high voltage igbt module driver transistors rectifier 650V 1200V

Mai Gyara Gadar Diode ABS210

Rectifier diode 85HF 85HFR 1200V in stock

Russian rectifier diodes 2000A 1000V D253-2000-10 RECTIFY DIODES disc diode for converting DC and AC currents

Diode Bridge Rectifier DB207S Bridge Rectifier