Tiristores en liña | Semicondutores de potencia de alta calidade

PARÁMETROS DO PRODUTO

Descrición

Visión xeral dos diodos rectificadores

Os díodos rectificadores son dispositivos semicondutores utilizados principalmente para converter a corrente alterna (AC) en corrente continua (DC). Permiten que a corrente fluya facilmente nunha dirección mentres a bloquean na dirección oposta. Esta propiedade unidireccional fai que sexan compoñentes esenciais nas fontes de alimentación, procesamento de sinal, e varios circuítos electrónicos. Os díodos rectificadores poden manexar unha ampla gama de correntes e voltaxes, converténdoos en versátiles para numerosas aplicacións.

Características dos diodos rectificadores

Condutividade unidireccional: Facilita o fluxo de corrente só nunha dirección, bloqueando eficazmente a corrente inversa.

Manexo de alta corrente: Deseñado para transportar correntes de avance substanciais, adecuado para aplicacións de alta potencia.

Pico de tensión inversa (PIV): Pode soportar altas tensións inversas sen romper.

Baixa caída de tensión directa: Minimiza a perda de enerxía en forma de calor, mellorando a eficiencia.

Tempo de recuperación rápida: Pasa rapidamente de estados condutores a estados non condutores, beneficioso para aplicacións de alta frecuencia.

Estabilidade térmica: Mantén o rendemento nun amplo rango de temperaturas, garantindo a fiabilidade en diferentes condicións.

Tamaño compacto: O factor de forma pequeno facilita a integración en deseños electrónicos compactos.

Rentable: Ofrece unha solución económica para as necesidades de conversión de CA a CC.

Variedade de paquetes: Dispoñible en varias opcións de embalaxe para adaptarse a diferentes requisitos de montaxe.

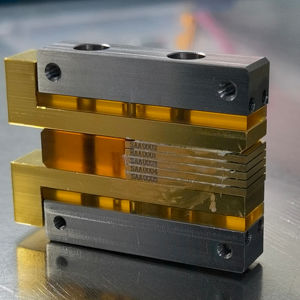

(12Rectificador de chapa V-4000A con inversión)

Specification of 12V-4000A plating rectifier with reversing

This rectifier supplies high power for requiring electroplating tasks. It supplies straight current result. The voltage changes efficiently from 0 a 12 volts DC. It deals with huge currents as much as 4000 amperes. This fits heavy commercial applications like large tank plating.

A crucial feature is automated reversing. This feature switches the existing direction instantly. It cycles in between forward (anodic) and reverse (cathodic) flow. The timing is flexible. You control the forward time period. You additionally control the reverse time duration. This cycle repeats continually throughout procedure. Reversing assists stop usual plating troubles. It minimizes undesirable build-up on sides. It minimizes tree-like growths. It battles roughness. This results in smoother, much more also metal down payments. Layer quality boosts considerably. Components look much better and last much longer.

The device utilizes dependable silicon regulated rectifier (SCR) tecnoloxía. SCRs switch power efficiently. They offer exact control over output. The design consists of solid transformers. These deal with the high existing safely. Cooling is crucial at this power level. The rectifier makes use of forced air cooling. Powerful followers maintain parts at risk-free temperatures. This avoids overheating throughout lengthy changes. Security circuits are constructed in. These guard against issues like brief circuits. They guard against overloads. They defend against overheating. This protects both the rectifier and your plating bath.

Digital meters present operating worths clearly. You see outcome voltage frequently. You see outcome present continuously. This permits very easy tracking. The control board provides straightforward changes. Set voltage simply. Set existing limits just. Set up the reversing times conveniently. The unit is built difficult for manufacturing facility conditions. It holds up against the severe plating setting. It stands up to rust well. Redúcense as demandas de mantemento.

(12Rectificador de chapa V-4000A con inversión)

Applications of 12V-4000A plating rectifier with reversing

This powerful 12V-4000A plating rectifier with reversing deals with demanding industrial steel finishing jobs. It takes care of thick, top notch electroplating deposits. You require this for chrome plating big parts like hydraulic cylinders or machine components. It layers nickel onto auto bumpers and trim pieces effectively. The high current makes certain quickly copper layering for circuit board manufacturing. It deposits zinc dependably onto steel fasteners and equipment for rust security.

The turning around function is important. It occasionally switches the present instructions. This breaks up irregular deposits during plating. You obtain smoother, brighter chrome and nickel coatings. Reversing protects against rough, plain layers. It likewise quits “burning” at sharp edges. This is crucial for decorative items requiring ideal look.

Turning around allows electrocleaning and removing as well. You remove old plating, rust, or range from steel surface areas prior to recoating. This prepares components perfectly for new plating. It recovers useful elements for reuse. The procedure cleans up detailed forms thoroughly.

This rectifier powers large layering tanks successfully. Its 4000A ability matches high-volume production lines. Factories layering automobile components count on it. Aerospace providers use it for important elements. Job stores dealing with varied layering tasks discover it flexible. The robust design takes care of continuous commercial procedure. It provides stable, precise DC power vital for constant plating high quality. You control voltage, presente, and timing cycles accurately. This ensures repeatable outcomes set after batch. The device withstands harsh chemical plant environments.

Perfil da empresa

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) é unha das empresas líderes en tecnoloxía de electrónica de potencia e produtos de enerxía, que participa plenamente no desenvolvemento de inversores solares, transformadores, reguladores de tensión, armarios de distribución, tiristores, módulos, díodos, quentadores, e outros dispositivos electrónicos ou semicondutores. Comprometémonos a ofrecer aos usuarios unha alta calidade, produtos eficientes e servizo atento.

Acepta pago con tarxeta de crédito, T/T, Unión Oeste, e Paypal. PDDN enviará os produtos aos clientes no exterior a través de FedEx, DHL, polo mar, ou por vía aérea. If you want high-quality 12V-4000A plating rectifier with reversing, por favor, envíenos consultas; estaremos aquí para axudarche.

Métodos de pago

L/C, T/T, Western Union, Paypal, Tarxeta de crédito, etc.

Envío

Por mar, polo aire, por expreso, como solicitan os clientes.

Condicións de almacenamento

1) Almacenar nun ambiente seco a temperatura ambiente.

2) Evite a humidade e a alta temperatura.

3) Use inmediatamente despois de abrir a bolsa de embalaxe interior.

5 FAQs of 12V-4000A plating rectifier with reversing

Aquí están 5 FAQs about the 12V-4000A Plating Rectifier with Reversing:

What does the reversing function do?

The reversing function switches the current direction. This is vital for electroplating processes needing metal stripping or specific deposit qualities. It helps remove imperfections during plating cycles. Smoother, more uniform metal layers result. This improves adhesion and reduces rejects.

How is the massive heat managed?

This rectifier generates significant heat at full load. A powerful internal cooling system handles it. Industrial-grade fans pull air through large heat sinks. This keeps critical components within safe operating temperatures. Consistent cooling prevents overheating shutdowns and extends equipment life.

Are safety features included?

Si, multiple safety features protect both the machine and operators. Standard protections guard against overloads, curtocircuítos, and overheating. Emergency stop buttons provide instant shutdown capability. Proper grounding and clear safety markings are essential. Always follow all safety protocols.

Can I control the plating cycle precisely?

Si, precise control is a key feature. Digital interfaces allow exact setting of voltage, actual, timing, and reverse cycle parameters. Operators program specific sequences for different plating jobs. Repeatable accuracy ensures consistent plating results batch after batch.

Que mantemento precisa?

Regular maintenance keeps the rectifier reliable. Check and clean air filters and cooling fans frequently. Inspect electrical connections for tightness and corrosion. Monitor output performance for any drift. Schedule professional inspections annually. Preventative care avoids unexpected downtime and costly repairs.

(12Rectificador de chapa V-4000A con inversión)

SOLICITA UN PRESUPUESTO

PRODUTOS RELACIONADOS

Diodo rectificador RL207 DO-15 2A 1000V

Genuine 6RA7025-6GS22-0 New Rectifier DC Governor In-stock Now On At Bargain s

SR160 1A 60V DO-41 Diode General Silicon Rectifiers 1000v 1W Power Max Through Hole

Componentes electrónicos rectificadores orixinais único díodo en stock

Diode Bridge Rectifier KBL410 Bridge Rectifier