Tiristoroj Enretaj | Altkvalitaj Potencaj Semikonduktaĵoj

PRODUCT PARAMETROJ

Priskribo

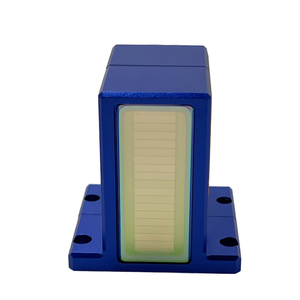

Superrigardo de Heatlinks

Varmegaj ligoj funkcias disponigante vojon de malalta termika rezisto inter varmofonto (kiel elektronika komponanto) kaj varmega lavujo aŭ malvarmiga sistemo. Ili povas esti precipe utilaj en medioj kie spaclimoj limigas la uzon de tradiciaj malvarmigaj metodoj, aŭ kiam pasiva termika administradsolvo estas preferita.

Varmegaj ligoj povas funkcii surbaze de malsamaj principoj, inkluzive de fazŝanĝaj materialoj, solidstata kondukado, aŭ eĉ fluid-bazitaj sistemoj. La elekto de teknologio dependas de la specifaj postuloj de la aplikaĵo, kiel funkcia temperaturo gamo, niveloj de disipado de potenco, kaj spacaj limoj.

Karakterizaĵoj de Heatlinks

Alta Termika Kondukto: Desegnita por oferti altan termikan konduktivecon, certigante efikan varmotransdonon de la fonto al la lavujo.

Kompakta Dezajno: Ofte kompakta, permesante al ili konveni en mallozaj spacoj ene de elektronikaj kunigoj aŭ alia ekipaĵo.

Pasiva Operacio: Kutime ne postulas eksteran potencon por funkcii, fidante anstataŭe sur la natura fluo de varmo de varmaj ĝis malvarmaj areoj.

Fortikeco kaj Fidindeco: Fabrikita por elteni ripetitajn termikajn ciklojn kaj severajn mediajn kondiĉojn sen degenero de rendimento.

Malalta Profilo: Maldikaj profiloj helpas minimumigi la efikon al la ĝenerala dezajno de produktoj.

Verstileco: Povas esti adaptita por konveni diversajn aplikojn, de konsumelektroniko ĝis industria maŝinaro kaj aerspacaj komponantoj.

Agordigebla: Havebla en malsamaj formoj, grandecoj, kaj konfiguracioj por renkonti specifajn dezajnbezonojn.

Kostefika: Provizu ekonomian solvon por termika administrado kompare kun pli kompleksaj malvarmigaj sistemoj.

Minimuma Prizorgado: Ĝenerale postulas malmulte al neniu prizorgado post instalite.

Ekologia Kongrueco: Desegnita por esti kongrua kun larĝa gamo de medioj, inkluzive de tiuj kiuj povas enhavi korodajn elementojn aŭ sperti signifajn temperaturfluktuojn.

(Personigita Alta Precizeca Aluminio Heatsink Ekstrudita Heatsink Radiatoro Anodize)

Specifications of Customized High Precision Aluminum Heatsink Extruded Heatsink Radiator Anodize

Customized high-precision aluminum heatsinks are engineered for optimal thermal management in electronics and industrial systems. These heatsinks use 6063 aŭ 6061 aluminum alloys, known for excellent thermal conductivity and durability. The extruded manufacturing process allows complex shapes and designs tailored to specific cooling requirements. Customization includes adjusting dimensions, fin density, base thickness, and surface finish to match application needs.

The extrusion method ensures tight tolerances, maintaining structural integrity while maximizing heat dissipation. Heat sinks undergo CNC machining for precise cuts, holes, kaj kaneloj, enabling seamless integration with components. Surface anodization is applied for corrosion resistance, electrical insulation, and improved aesthetics. Anodized layers come in colors like black, silver, or custom options, adding protection without compromising thermal performance.

High fin density designs increase surface area, enhancing heat transfer efficiency. Base thickness is optimized to balance weight and thermal capacity. These heatsinks work with passive and active cooling systems, supporting natural convection or forced airflow. Applications include LED lighting, elektrofontoj, automotive electronics, and computer hardware.

Material quality is verified through strict testing for thermal conductivity, hardness, and dimensional accuracy. Anodized coatings undergo adhesion and thickness checks to ensure long-term reliability. Custom designs accommodate unique space constraints or thermal loads, providing flexibility for specialized projects.

Thermal simulations and prototyping are available to validate performance before mass production. This reduces development time and ensures compatibility with target systems. Production lead times vary based on design complexity, with options for small or large batches.

Packaging is designed to prevent damage during shipping, using anti-static materials when required. Technical support assists with design optimization, material selection, and post-installation guidance. These heatsinks meet industry standards for safety and performance, suitable for demanding environments.

Cost-effectiveness is achieved through efficient manufacturing and scalable processes. Bulk orders receive competitive pricing without sacrificing quality. Environmental considerations include recyclable materials and energy-efficient production methods.

Compatibility with thermal interface materials like pads or pastes ensures low thermal resistance at contact points. Installation is simplified with pre-drilled holes or mounting brackets. Custom logos or labels can be added for branding purposes.

Performance metrics include thermal resistance values, heat dissipation rates, and temperature drop benchmarks. Data sheets provide detailed specifications for engineers to evaluate suitability. Samples are available for testing prior to full-scale adoption.

(Personigita Alta Precizeca Aluminio Heatsink Ekstrudita Heatsink Radiatoro Anodize)

Applications of Customized High Precision Aluminum Heatsink Extruded Heatsink Radiator Anodize

Customized high-precision aluminum heatsinks made through extrusion and anodizing are essential for managing heat in many industries. These products are designed to transfer heat away from sensitive components. They prevent overheating. This improves performance. Aluminum is used because it is lightweight. It also conducts heat well. Extrusion shapes the metal into complex profiles. This maximizes surface area. More surface area means better cooling.

These heatsinks are tailored to fit specific devices. Custom sizes and shapes match unique requirements. They work in electronics like computers and LED lighting. They handle high power levels. They keep systems stable. Automotive systems use them in electric vehicles and battery units. They manage heat from motors and power electronics. This extends the lifespan of parts.

Anodizing adds a protective layer. It prevents corrosion. It increases durability. The finish resists wear. It works in harsh environments. Colors can be added for branding. This does not affect performance.

Industrial machines use these heatsinks in automation and power supplies. They cool components during heavy operations. Renewable energy systems like solar inverters rely on them. They maintain efficiency in energy conversion. Telecommunications equipment uses them for base stations and servers. Heat management prevents signal loss.

The extrusion process allows precise designs. Thin fins and dense patterns improve airflow. Heat dissipates faster. This reduces the need for extra cooling parts. It saves space and cost.

High-precision manufacturing ensures tight tolerances. Components fit perfectly. Neniuj alĝustigoj estas bezonataj. This speeds up assembly. It reduces errors.

These heatsinks are reliable in demanding conditions. They handle high temperatures. They resist moisture and chemicals. This makes them suitable for outdoor and industrial use.

Customization options include hole patterns and mounting features. They integrate smoothly into existing setups. This flexibility meets diverse needs. It supports innovation in product design.

Kompanio Profilo

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) estas unu el la ĉefaj entreprenoj en elektronika teknologio kaj potencaj produktoj, kiu estas plene implikita en evoluigado de sunaj invetiloj, transformiloj, reguligiloj de tensio, distribuaj kabinetoj, tiristoroj, moduloj, diodoj, hejtiloj, kaj aliaj elektronikaj aparatoj aŭ duonkonduktaĵoj. Ni devontiĝos provizi uzantojn per altkvalita, efikaj produktoj kaj zorgema servo.

Ĝi akceptas pagon per Kreditkarto, T/T, Okcidenta Unio, kaj Paypal. PDDN sendos la varojn al klientoj eksterlande per FedEx, DHL, per maro, aŭ per aero. If you want high-quality Customized High Precision Aluminum Heatsink Extruded Heatsink Radiator Anodize, bonvolu sendi al ni demandojn; ni estos ĉi tie por helpi vin.

Pag-Metodoj

L/C, T/T, Okcidenta Unio, Paypal, Kreditkarto ktp.

Sendo

Ĉe la maro, per aero, per ekspreso, kiel klientoj petas.

Kondiĉoj de Stokado

1) Konservu en seka medio ĉe ĉambra temperaturo.

2) Evitu malsekan kaj altan temperaturon.

3) Uzu tuj post malfermi la internan pakan sakon.

5 FAQs of Customized High Precision Aluminum Heatsink Extruded Heatsink Radiator Anodize

What are the customization options for high-precision aluminum heatsinks? Custom heatsinks can be tailored in size, shape, and surface finish. Extrusion allows complex designs to match specific thermal needs. Anodizing offers color choices like black or silver. Custom hole patterns or mounting features are added based on device requirements. The goal is ensuring the heatsink fits perfectly into the target application.

Why use aluminum for heatsink radiators? Aluminum moves heat efficiently. It is lightweight, preventing extra stress on devices. The material resists corrosion naturally. Anodizing boosts this resistance further. Aluminum costs less than copper while offering strong thermal performance. These factors make it a common choice for electronics cooling.

How does anodizing improve heatsink performance? Anodizing adds a protective oxide layer to aluminum. This layer prevents rust and wear. It also helps the surface release heat faster. Anodized colors like black can improve heat radiation through better emissivity. The process extends the heatsink’s lifespan in harsh environments.

What’s the difference between extruded and other heatsinks? Extruded heatsinks are made by pushing aluminum through a shaped die. This creates long, uniform profiles with detailed fins. Stamped or bonded heatsinks have simpler shapes. Extrusion allows more complex designs for better cooling. It is cost-effective for medium to high production volumes.

How is quality ensured in custom heatsinks? Manufacturers test samples for size accuracy and heat dissipation. Thermal resistance checks confirm the heatsink meets design specs. Stress tests simulate real-world conditions. Certifications like ISO 9001 guarantee consistent processes. Strict quality control prevents defects and ensures reliability.

(Personigita Alta Precizeca Aluminio Heatsink Ekstrudita Heatsink Radiatoro Anodize)

PETU KITTON

RELATAJ PRODUTOJ

High-Performance Air Cooling Solution for NVMe/SATA M.2 SSDs – Premium Aluminum Heatsink with Silicone Thermal Pad for Optimal PC Performance

Anstataŭa tekkomputilo CPU GPU Varmodisipilo Por HP Zbook 17 G3 N16E Varmodisipilo 906114-001 850110-001

CoolCox GPU Cooler VC-AL4009 12V varmodisipilo 41x40x9.8mm Vga Cooler Ventilo Generatoro Radiatora Ventilo Grafika Karto Ventilo

tiristoraj akvo-malvarmigaj varmodisipiloj SS14

Alta Potenco Propra Aluminia Potenco-Amplifilo Rektangula Gvidita Trinkejo varmolavujo Profilaj Eltrudaj Radiatoroj Aluminia Varmolavujo