Tiristori in linea | Semicondutturi di putenza di alta qualità

PARAMETRI DI PRODUTTIU

Descrizzione

Panoramica di Diodi Rectifier

I diodi Rectifier sò dispusitivi semiconduttori utilizati principalmente per a cunversione di corrente alternata (AC) in corrente continua (DC). Permettenu a corrente di flussu facilmente in una direzzione mentre u bluccanu in a direzione opposta. Questa pruprietà unidirezionale li rende cumpunenti essenziali in l'alimentazione elettrica, trasfurmazioni di signali, è diversi circuiti elettronichi. I diodi Rectifier ponu trattà una larga gamma di currenti è tensioni, rendenduli versatili per parechje applicazioni.

Caratteristiche di diodi Rectifier

Conduttività unidirezionale: Facilita u flussu di corrente in una sola direzzione, bluccà in modu efficace a corrente inversa.

Trattamentu di alta corrente: Cuncepitu per trasportà correnti in avanti sustanziali, adattatu per applicazioni di alta putenza.

Peak Inverse Voltage (PIV): Pò resiste à alte tensioni inverse senza rompe.

Caduta di tensione in avanti bassa: Minimize a perdita di energia cum'è calore, migliurà l'efficienza.

Tempu di ricuperazione rapida: Transizioni rapidamente da stati conduttivi à stati non conduttivi, benefica per l'applicazioni à alta frequenza.

Stabilità termale: Mantene u rendiment in una larga gamma di temperatura, assicurendu affidabilità in diverse cundizioni.

Taglia compacta: Picculu fattore di forma facilita l'integrazione in disinni elettronici compacti.

Cost-Effective: Fornisce una soluzione ecunomica per i bisogni di cunversione AC-to-DC.

Varietà di pacchetti: Disponibile in parechje opzioni di imballaggio per adattà à diverse esigenze di muntatura.

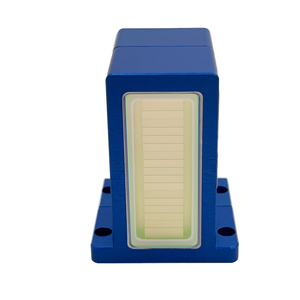

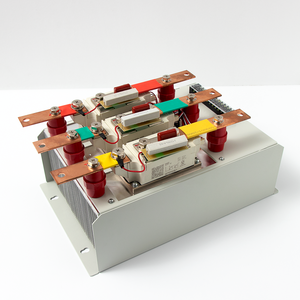

(400V welding machine rectifier diode for rectifier)

Specification of 400V welding machine rectifier diode for rectifier

This 400V welding device rectifier diode is a core part. It manages the critical job of transforming rotating current (ARIA CONDICIONATA) right into straight present (DC). This DC current is necessary for secure, regulated welding arcs. The diode is built for requiring industrial settings. Its 400V ranking is vital. This voltage rating ensures it can hold up against the high reverse voltages typical in welding rectifiers. It avoids break down throughout procedure. These diodes manage extremely high electrical currents. They must maintain the hefty amperage needs of welding makers without failure. Heat generation is a major variable. These diodes create substantial heat under tons. Efficient warm dissipation is required. They are generally placed onto large, significant warmth sinks. These warmth sinks draw the warm far from the diode junction. Reliable cooling preserves performance. It stops premature failing. Dependability is non-negotiable in welding. This diode provides constant efficiency cycle after cycle. It minimizes downtime. I prezzi di mantenimentu restanu ridotti. The construction is robust. It makes use of resilient semiconductor materials. The product packaging is designed for high thermal stability. This ensures lengthy service life also under difficult conditions. Using this diode guarantees the rectifier operates properly. The welding maker delivers stable DC output. This leads to cleaner welds. Arc stability boosts considerably. Operators experience far better control. Total welding performance boosts. The diode’s requirements match the extensive requirements of professional welding equipment.

(400V welding machine rectifier diode for rectifier)

Applications of 400V welding machine rectifier diode for rectifier

400V welding machine rectifier diodes are crucial parts inside welding devices. They execute one important task. They transform alternating existing (AIR CONDITIONER) power right into straight present (DC) putenza. This DC power is required for stable, controlled welding arcs. These diodes deal with high voltage especially. The 400V rating implies they take care of the electric stress inside industrial welders safely. This stops damages. It makes sure trusted device procedure.

Industrial MIG welders make use of these diodes heavily. MIG welding needs smooth, consistent DC result. The diodes give this. They allow solid, clean welds on thick steel. Fabrication stores depend on this performance daily. TIG welding tools also depends upon these elements. Precise TIG arcs need steady DC current. The diodes deliver this security. This permits top notch welds on thinner materials like stainless-steel or light weight aluminum.

Stick welding equipments profit also. Excellent stick welding requires effective, steady DC output. The 400V diodes take care of the heavy electric loads. Construction websites and repair work usage stick welders typically. These diodes stand up to challenging conditions. They take care of heat. They take care of power surges. They handle continuous vibration. Their rugged layout makes them reliable.

Makers construct these diodes hard. They use materials like silicon. These materials deal with high temperatures well. Heat sinks are common. They draw excess heat away. This safeguards the diode. It expands its functioning life. Proper cooling is vital. Welding creates considerable warm inside. The diode should cope.

The 400V rating is essential. It matches common industrial power supplies. It makes sure compatibility. It offers safety and security margins. Voltage spikes happen throughout welding. The diode has to make it through these spikes. A 400V rating offers this defense. It protects against sudden diode failure. Device downtime is costly. Trusted diodes avoid this. They maintain production moving. They minimize repair work costs. Picking the right voltage diode issues. Utilizing a lower-rated diode threats disastrous failure. It takes the chance of harming the entire welding rectifier. The 400V diode is the safe, conventional selection for durable equipment.

Profilu di a cumpagnia

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) hè una di l'imprese principali in a tecnulugia di l'elettronica di putenza è i prudutti di l'energia, chì hè cumplettamente implicatu in u sviluppu di inverter solari, trasformatori, regulatori di tensione, armadi di distribuzione, tiristori, moduli, diodi, riscaldatori, è altri apparecchi elettronichi o semiconduttori. Seremu impegnati à furnisce l'utilizatori cù alta qualità, prudutti efficaci è serviziu attentu.

Accepta pagamentu via Carta di Creditu, T/T, Unione Occidentale, è Paypal. PDDN spedirà e merchenzie à i clienti oltremare attraversu FedEx, DHL, per mare, o per l'aria. If you want high-quality 400V welding machine rectifier diode for rectifier, per piacè mandateci dumande; seremu quì per aiutà vi.

I metudi di pagamentu

L/C, T/T, Western Union, Paypal, Carta di creditu ecc.

Spedizioni

Per mare, per l'aria, per espresso, cum'è i clienti dumandanu.

Cundizioni di almacenamiento

1) Mantene in un ambiente seccu à a temperatura di l'ambienti.

2) Evite l'umidità è a temperatura alta.

3) Aduprà immediatamente dopu l'apertura di u saccu di imballaggio internu.

5 FAQs of 400V welding machine rectifier diode for rectifier

Eccu 5 FAQs about 400V welding machine rectifier diodes:

What does the rectifier diode do? Cambia a putenza AC in DC. Welding arcs need stable DC current. The diode makes this happen. Agisce cum'è una valvula unidirezionale per l'electricità.

How do I know if a diode fails? Look for obvious damage first. Burnt marks or cracks are bad signs. The welding arc might become weak or unstable. You might see sparks inside the machine. The machine could overheat fast. Output might drop completely. Check diodes with a multimeter if possible.

Can I replace just one diode? Usually not. Diodes work together in a set called a bridge. If one fails, others often get damaged too. Replace the whole rectifier assembly. This is safer. It prevents more problems later. Check the manufacturer’s advice.

Are all 400V diodes the same? Innò. Voltage rating is crucial. Use 400V or higher. Current rating matters too. It must match your machine’s output. Physical size and mounting style differ. Get the exact replacement part. Using the wrong diode causes failure.

How long do these diodes last? It depends heavily on use. Normal conditions give years of service. Heavy use or overloads shorten life. Poor cooling kills diodes fast. Electrical surges are bad. Good maintenance helps. Keep the machine clean. Ensure cooling fans work. Avoid pushing the machine too hard.

(400V welding machine rectifier diode for rectifier)

RICHIEDE UN QUOTE

PRODOTTI RELATI

6Diode raddrizzatore generale A10 1000v 6a05-6a10 diodu mic

Rectifier Bridge Diode S35VB S35VB60 Cù Originale

Diode Rectifier R-6 20A10 20A 1000V Diode

NEW Rectifiers 600V 14A DSEI12-06A In Stock

IN4007 1A 1kv DO-214AC General Silicon Rectifiers Diode 1000v Rectifier 1N4007 Diode 1W Max Power