Thyristors Online | High-Quality Power Semiconductors

The Mighty Thyristor Rectifier: Power’s Silent Conductor

(What Is Thyristor Rectifier)

Ever wonder how massive industrial machines get their steady, powerful DC electricity? Or how electric trains accelerate so smoothly? Behind the scenes, a tough workhorse called the thyristor rectifier often makes it happen. This isn’t your average plug. It’s a master controller of electrical power. Let’s uncover what makes this device tick and why it matters.

Main Product Keyword: Thyristor Rectifier

1. What Exactly is a Thyristor Rectifier?

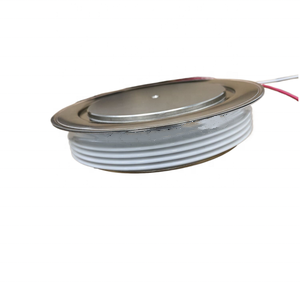

Think of it as a super-smart electrical switch. It combines two key parts: thyristors (also called SCRs – Silicon Controlled Rectifiers) and a control system. Its main job? Converting alternating current (AC) into direct current (DC). But it doesn’t just convert. It controls the DC output very precisely. Unlike simple diodes, a thyristor rectifier uses those thyristors. These act like switches you can turn on with a signal. Once on, they stay on until the current stops. This on/off control happens incredibly fast. The result is DC power you can adjust. Need more voltage? The control system tells the thyristors to switch on earlier in the AC wave. Need less? It switches them on later. This fine control is its superpower.

2. Why Choose a Thyristor Rectifier?

Several big reasons make these units the go-to solution for heavy-duty power. First, they handle enormous power levels. We’re talking thousands of volts and amps. This makes them perfect for big jobs. Second, they offer precise control. You can dial in the exact DC voltage or current you need. This is crucial for processes needing steady power. Third, they are robust and reliable. Built tough, they last a long time in harsh environments like factories. Fourth, they are efficient. They waste very little power as heat during conversion. This saves energy and money. Fifth, they provide smooth control. Unlike mechanical switches, they change power levels instantly without bumps or sparks. For large-scale, controlled DC power, few alternatives match the thyristor rectifier’s muscle and smarts.

3. How Does a Thyristor Rectifier Work?

Picture the AC power coming in like a wavy line (a sine wave). The thyristor rectifier uses its thyristors like gates. These gates normally block the current. The control system sends precise timing pulses (gate signals) to each thyristor. This tells each one exactly when to open its gate during the AC wave. When a thyristor gets its pulse, it opens. It lets the current flow through until that part of the AC wave naturally drops to zero. Then it shuts off. The control system constantly adjusts the timing of these pulses. Firing the thyristors early in the wave cycle lets more voltage through. Firing them later lets less voltage through. Multiple thyristors work together. They switch on and off in sequence. This chops up the AC wave. It then reassembles it into a smooth, controllable DC output. The complexity lies in the control system’s brain. It must time those pulses perfectly for the desired result.

4. Where Do We Use Thyristor Rectifiers?

These powerhouses are everywhere heavy DC power is needed. Look inside large industrial plants. They power electroplating lines, controlling the metal deposited on parts. They drive electrolysis processes for making chemicals or aluminum. They supply the steady current for DC motor drives. Think of huge rolling mills in steel plants or mining equipment. Electric traction is another major area. Modern electric trains, trams, and subway cars rely on them. They convert overhead AC power into the variable DC needed to control the train’s speed smoothly. Battery charging stations for forklifts or electric vehicles often use them. They provide the high currents needed fast. High-voltage direct current (HVDC) transmission systems use massive thyristor rectifiers. They convert AC to DC for efficient long-distance power lines. Anywhere you need lots of controlled DC power, a thyristor rectifier is likely involved.

5. Thyristor Rectifier FAQs

(What Is Thyristor Rectifier)

Let’s tackle some common questions. Do they generate a lot of heat? Yes, handling high power creates heat. They need good cooling like fans or water jackets. Can they convert DC to AC? No. They only convert AC to DC. For DC to AC, you need an inverter. Are they noisy? Not usually. The main sound might be cooling fans. The electrical switching itself is silent. How long do they last? They are very reliable. With proper cooling and maintenance, they can last decades. Thyristors themselves rarely fail. What’s the difference between a diode rectifier and a thyristor rectifier? Diode rectifiers are simpler and cheaper. They convert AC to DC. But they offer no control over the output voltage. A thyristor rectifier gives you full control over the output. Are they expensive? Initially, yes, more than simple diode rectifiers. But their precise control and efficiency often save money over time. They prevent wasted energy and protect expensive equipment. What about maintenance? They need regular checks. Look for dust buildup on heatsinks. Ensure cooling systems work. Check electrical connections are tight. The control electronics might need occasional calibration. Overall, they are low-maintenance workhorses.