Thyristors Online | High-Quality Power Semiconductors

Thyristors: The Tiny Traffic Cops of Your Inverter

(How Thyristors Work In An Inverter)

Ever wonder how your solar panels power your TV, or how an electric car zooms silently? A big part of that magic happens inside an inverter. Its job is simple but crucial: turn direct current (DC) power into the alternating current (AC) power our homes and gadgets crave. And deep inside many powerful inverters, you’ll find thyristors working hard. Think of them as super-tough electronic switches, but way smarter than a simple light switch.

So what’s special about a thyristor? It’s a solid-state device with layers of semiconductor material. It usually blocks current, acting like a closed gate. Give its ‘gate’ terminal a quick pulse of current, though, and it snaps wide open. Now here’s the cool part: once it turns on, it stays on. It latches. You can take away the gate signal, and the thyristor keeps conducting electricity as long as current keeps flowing through it. It only turns off when that main current drops nearly to zero. This latching action is key to their job in inverters.

An inverter takes smooth, steady DC power – like from a battery or solar panel – and chops it up. It needs to create a wavy AC output. That means flipping the current direction back and forth many times a second. Transistors can do this switching too, often faster. But thyristors have a big advantage: they handle massive amounts of power without breaking a sweat. For high-power applications like industrial motors or big solar farms, thyristors are often the go-to choice because they’re rugged and efficient at handling high voltages and currents.

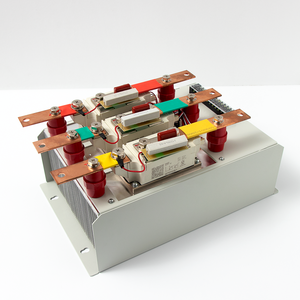

Inside the inverter circuit, thyristors act like precise traffic controllers for electricity. They are arranged in specific patterns, often called bridges. The inverter’s control brain sends carefully timed signals to the thyristor gates. Tell one thyristor to turn on at just the right moment, and it connects the DC source to the output, pushing current in one direction. A fraction of a second later, tell another thyristor to turn on. This one connects the source differently, pulling current the opposite way. By rapidly switching different thyristors on and off in sequence, the inverter builds that up-and-down, back-and-forth AC waveform.

The control is everything. The timing of those gate pulses determines the frequency of the AC output. How long each thyristor stays on shapes the voltage level. Sophisticated control circuits constantly adjust this timing to create a clean, stable sine wave, even when the load changes. It’s a high-speed dance of switching, managed by those latching thyristor switches.

(How Thyristors Work In An Inverter)

Thyristors aren’t perfect for every inverter. Turning them off requires the current to naturally drop to zero, which can limit how fast they switch compared to transistors. This makes them less ideal for very high-frequency applications. They also need specific circuits to force them off if needed. But for brute strength, reliability, and handling enormous power levels efficiently, thyristors are incredibly tough workhorses. They form the backbone of many large-scale power conversion systems, quietly doing the heavy lifting to turn raw DC into usable AC power. Next time you flip a switch powered by an inverter, remember the tiny traffic cops inside, directing the flow.