Thyristors መስመር ላይ | ከፍተኛ ጥራት ያለው ኃይል ሴሚኮንዳክተሮች

የምርት መለኪያዎች

መግለጫ

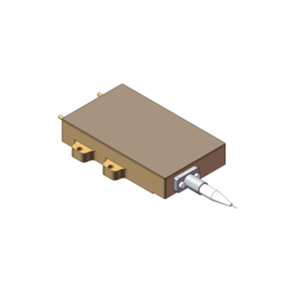

የHeatlinks አጠቃላይ እይታ

Heatlinks የሚሠሩት በሙቀት ምንጭ መካከል ዝቅተኛ የሙቀት መከላከያ መንገድን በማቅረብ ነው። (እንደ ኤሌክትሮኒክ አካል) እና የሙቀት ማጠራቀሚያ ወይም የማቀዝቀዣ ዘዴ. በተለይም የቦታ ገደቦች ባህላዊ የማቀዝቀዣ ዘዴዎችን መጠቀም በሚገድቡባቸው አካባቢዎች ጠቃሚ ሊሆኑ ይችላሉ።, ወይም ተገብሮ የሙቀት አስተዳደር መፍትሔ ይመረጣል ጊዜ.

የሙቀት ማገናኛዎች በተለያዩ መርሆዎች ላይ በመመስረት ሊሠሩ ይችላሉ, የደረጃ ለውጥ ቁሳቁሶችን ጨምሮ, ጠንካራ-ግዛት conduction, ወይም ፈሳሽ-ተኮር ስርዓቶች እንኳን. የቴክኖሎጂ ምርጫ በመተግበሪያው ልዩ መስፈርቶች ላይ የተመሰረተ ነው, እንደ ኦፕሬቲንግ የሙቀት መጠን, የኃይል ብክነት ደረጃዎች, እና የቦታ ገደቦች.

የ Heatlinks ባህሪያት

ከፍተኛ የሙቀት አማቂነት: ከፍተኛ የሙቀት መቆጣጠሪያን ለማቅረብ የተነደፈ, ውጤታማ የሆነ ሙቀትን ከምንጩ ወደ ማጠቢያ ገንዳ ማረጋገጥ.

የታመቀ ንድፍ: ብዙውን ጊዜ የታመቀ, በኤሌክትሮኒካዊ ስብሰባዎች ወይም ሌሎች መሳሪያዎች ውስጥ ወደ ጥብቅ ቦታዎች እንዲገቡ ያስችላቸዋል.

ተገብሮ ክወና: በተለምዶ ለመስራት ውጫዊ ኃይልን አይጠይቁ, ከሙቀት ወደ ቀዝቃዛ አካባቢዎች በተፈጥሯዊ የሙቀት ፍሰት ላይ በመተማመን.

ዘላቂነት እና አስተማማኝነት: ተደጋጋሚ የሙቀት ዑደቶችን እና አስቸጋሪ የአካባቢ ሁኔታዎችን የመቋቋም አቅም ሳይቀንስ የተሰራ.

ዝቅተኛ መገለጫ: ቀጭን መገለጫዎች በምርቶች አጠቃላይ ንድፍ ላይ ያለውን ተጽእኖ ለመቀነስ ይረዳሉ.

ሁለገብነት: ለተለያዩ አፕሊኬሽኖች ተስማሚ ሆኖ ሊዘጋጅ ይችላል, ከሸማች ኤሌክትሮኒክስ እስከ የኢንዱስትሪ ማሽነሪዎች እና የኤሮስፔስ ክፍሎች.

ሊበጅ የሚችል: በተለያዩ ቅርጾች ይገኛል።, መጠኖች, እና የተወሰኑ የንድፍ ፍላጎቶችን ለማሟላት ውቅሮች.

ወጪ ቆጣቢ: በጣም ውስብስብ ከሆኑ የማቀዝቀዣ ዘዴዎች ጋር ሲነፃፀር ለሙቀት አስተዳደር ኢኮኖሚያዊ መፍትሄ ይስጡ.

አነስተኛ ጥገና: ከተጫነ በኋላ በአጠቃላይ ትንሽ እና ምንም ጥገና አያስፈልግም.

የአካባቢ ተስማሚነት: ከተለያዩ አካባቢዎች ጋር ተኳሃኝ እንዲሆን የተነደፈ, የሚበላሹ ንጥረ ነገሮችን ሊይዙ የሚችሉ ወይም ከፍተኛ የሙቀት መጠን መለዋወጥ ሊያጋጥማቸው የሚችሉትን ጨምሮ.

(Anodized Heatsinks CNC Machining Aluminum Parts)

Specifications of Anodized Heatsinks CNC Machining Aluminum Parts

Plated heatsinks made via CNC machining from light weight aluminum offer high performance and resilience. These components handle warm administration in electronic gadgets and commercial systems. The aluminum used is quality 6061 ወይም 6063. These grades equilibrium toughness, weight, and thermal conductivity. CNC machining guarantees exact shapes and limited tolerances. Parts remain consistent even in intricate designs. Machined surface areas get smooth coatings prior to plating. This step prepares them for better coating attachment.

The anodizing procedure includes immersing parts in an electrolyte solution. An electrical present forms a protective oxide layer. This layer stands up to rust and wear. Anodized surface areas approve dyes for shade coding or branding. Securing the oxide layer closes tiny pores. This improves sturdiness and maintains appearance secure in time. Plated heatsinks dissipate warmth quicker than untreated light weight aluminum. The oxide layer boosts surface area emissivity. Warm transfers a lot more successfully to the bordering air.

Modification choices include size modifications, shape modifications, and fin density modifications. CNC makers adapt to specific design needs quickly. Slim fins or intricate patterns preserve architectural honesty. These heatsinks match small rooms without shedding cooling power. Usual applications include computers, LED illumination, የኃይል አቅርቦቶች, እና ራስ-ሰር ስርዓቶች. They work in environments with heats or resonance.

Quality checks occur at every phase. Dimensional accuracy is verified using calibrated devices. Finishing thickness fulfills industry standards like MIL-A-8625. Evaluating consists of thermal biking and salt spray direct exposure. Problems like fractures or unequal coatings obtain rejected early. This guarantees trustworthy performance in real-world problems.

Light weight aluminum is recyclable. CNC machining creates marginal waste. Scrap product obtains reused in new jobs. Anodizing uses non-toxic chemicals. Wastewater undertakes treatment before disposal. These actions decrease environmental influence.

Plated heatsinks require little maintenance. The oxide layer protects against oxidation. Cleaning needs are straightforward– wipe with a completely dry cloth or light detergent. Prevent unpleasant tools to shield the finish. Appropriate setup guarantees maximum call with warm resources. Thermal paste or pads boost warm transfer effectiveness.

(Anodized Heatsinks CNC Machining Aluminum Parts)

Applications of Anodized Heatsinks CNC Machining Aluminum Parts

Plated heatsinks made with CNC machining play a vital duty in handling warm throughout industries. These aluminum components deal with heats successfully. Electronics depend on them for cooling elements like CPUs and GPUs. Their exact designs fit securely right into small tools. This prevents overheating and makes certain steady efficiency.

The automobile industry utilizes these heatsinks in electric cars and onboard systems. CNC machining produces shapes that maximize area. This enhances warmth dissipation from batteries and power electronics. Anodization includes deterioration resistance. This safeguards parts from wetness and chemicals in rough environments.

Aerospace applications require integrity. Anodized heatsinks cool down avionics and interaction systems. CNC-machined light weight aluminum is lightweight. This minimizes aircraft weight while preserving strength. The anodized layer withstands extreme temperature levels during flight.

LED lights systems utilize these heatsinks to extend lifespan. High-power LEDs create substantial heat. Custom-made CNC creates direct warmth far from delicate parts. Plated coatings boost thermal conductivity. They also provide a tidy, durable surface area for visual charm.

Telecom equipment depends on plated heatsinks for base stations and web servers. Constant procedure creates consistent warmth accumulation. Efficient air conditioning avoids downtime. CNC machining permits complex geometries. These suit limited areas without giving up performance.

Plated aluminum withstands wear and electric interference. This makes it ideal for commercial machinery. CNC precision ensures parts fulfill rigorous tolerances. Custom shapes and sizes adapt to certain cooling needs.

The process integrates durability with cost-effectiveness. CNC machining produces high volumes with uniformity. Anodizing includes minimal additional price. This makes the heatsinks cost effective for mass production. Their lengthy service life lowers substitute frequency.

These heatsinks support renewable energy systems like solar inverters. Warm monitoring is vital for keeping performance. Anodized surfaces take care of outdoor exposure. CNC machining makes sure parts incorporate effortlessly into existing arrangements.

Clinical gadgets call for specific temperature level control. Anodized heatsinks cool imaging systems and analysis tools. Non-toxic, easy-to-clean surfaces satisfy health standards. CNC accuracy makes certain compatibility with fragile tools.

Performance and integrity drive their usage. Industries select plated CNC heatsinks for reliable thermal solutions. The mix of sophisticated production and protective coatings meets varied needs.

የኩባንያው መገለጫ

ሉኦያንግ ዳታንግ ኢነርጂ ቴክ Co.Ltd(sales@pddn.com) በሃይል ኤሌክትሮኒክስ ቴክኖሎጂ እና በሃይል ምርቶች ግንባር ቀደም ከሆኑ ኢንተርፕራይዞች አንዱ ነው።, የፀሐይ ኢንቬንተሮችን በማዘጋጀት ሙሉ በሙሉ የተሳተፈ, ትራንስፎርመሮች, የቮልቴጅ መቆጣጠሪያዎች, የማከፋፈያ ካቢኔቶች, thyristors, ሞጁሎች, ዳዮዶች, ማሞቂያዎች, እና ሌሎች የኤሌክትሮኒክስ መሳሪያዎች ወይም ሴሚኮንዳክተሮች. ለተጠቃሚዎች ከፍተኛ ጥራት ያላቸውን ለማቅረብ ቁርጠኞች እንሆናለን።, ውጤታማ ምርቶች እና አሳቢ አገልግሎት.

በክሬዲት ካርድ በኩል ክፍያ ይቀበላል, ቲ/ቲ, ዌስት ዩኒየን, እና Paypal. PDDN እቃዎቹን በፌዴክስ በኩል ወደ ባህር ማዶ ላሉ ደንበኞች ይልካል።, ዲኤችኤል, በባህር, ወይም በአየር. If you want high-quality Anodized Heatsinks CNC Machining Aluminum Parts, እባክዎን ጥያቄዎችን ይላኩልን።; እርስዎን ለመርዳት እዚህ እንሆናለን።.

የመክፈያ ዘዴዎች

ኤል/ሲ, ቲ/ቲ, ዌስተርን ዩኒየን, Paypal, ክሬዲት ካርድ ወዘተ.

መላኪያ

በባህር, በአየር, በመግለፅ, ደንበኞች እንደሚጠይቁ.

የማከማቻ ሁኔታዎች

1) በክፍል ሙቀት ውስጥ በደረቅ አካባቢ ያከማቹ.

2) እርጥበት እና ከፍተኛ ሙቀትን ያስወግዱ.

3) የውስጥ ማሸጊያ ቦርሳውን ከከፈቱ በኋላ ወዲያውኑ ይጠቀሙ.

5 FAQs of Anodized Heatsinks CNC Machining Aluminum Parts

Anodized heatsinks made with CNC machining are common in electronics and industrial uses. People often ask what anodized heatsinks do. They help transfer heat away from sensitive parts. The anodizing process adds a protective layer to aluminum. This layer prevents corrosion and improves durability.

Many want to know why CNC machining is used for these heatsinks. CNC machines shape aluminum with high precision. This accuracy ensures heatsinks fit perfectly into devices. Complex designs are possible. Tight tolerances keep performance consistent.

A frequent question is about the benefits of aluminum for heatsinks. Aluminum is lightweight and conducts heat well. It resists rust and handles high temperatures. Anodizing boosts these traits. Aluminum costs less than copper or other metals.

People ask if custom designs are possible. CNC machining allows custom shapes and sizes. Specific patterns or holes can be added. Engineers adjust designs based on thermal needs. Prototypes are tested before full production.

Durability is another common concern. Anodized aluminum lasts longer than untreated metal. The coating resists scratches and chemicals. It handles harsh environments without degrading. Regular cleaning maintains performance over time.

(Anodized Heatsinks CNC Machining Aluminum Parts)

ጥቅስ ጠይቅ

ተዛማጅ ምርቶች

ብጁ ከፍተኛ ትክክለኛነት የአልሙኒየም የሙቀት አማቂ የራዲያተር አኖዳይዝ

የኦሪጂናል ዕቃ አምራች ብጁ የአልሙኒየም ኤክስትሬትድ የሙቀት አማቂ የአሉሚኒየም ሙቀት ማጠቢያ

ከፍተኛ የኃይል ኢንቫተር የኃይል አቅርቦት ሙቀት ማስመጫ ብጁ የአልሙኒየም ስኪቪንግ ጥቅጥቅ ያለ ቀጭን ክንፍ የሙቀት ማስተላለፊያ

High quality stainless steel heatsink plate 201 210 304 316 316ኤል 410 420 steel plates food grade stainless steel plate

Heatsink