Tyristors aanlyn | Hoë-gehalte krag halfgeleiers

PRODUKPARAMETERS

Beskrywing

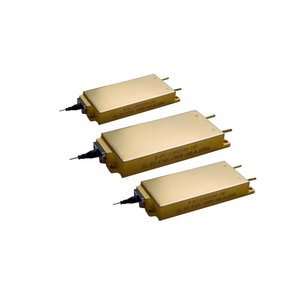

Oorsig van (B6C)2 Reeks Byeenkomste

(B6C)2 Reekssamestellings is ontwerp om voortreflike werkverrigting te lewer in omgewings waar akkuraatheid is, duursaamheid, en doeltreffendheid is uiters belangrik. Hulle is ontwerp om aan streng industriestandaarde te voldoen en kan aangepas word vir spesifieke toepassingsvereistes. Die reeks is bekend daarvoor om komplekse funksionaliteite in kompakte ontwerpe te integreer, die algehele voetspoor te verminder terwyl operasionele vermoëns verbeter word.

Hierdie samestellings kan geïntegreerde stroombane insluit, sensors, aktueerders, koppelaars, en ander elektroniese of meganiese komponente wat naatloos saamwerk. Die ontwerpfilosofie agter (B6C)2 Reeks beklemtoon modulariteit, wat maklike opgraderings en instandhouding moontlik maak sonder om prestasie in te boet.

Kenmerke van (B6C)2 Reeks Byeenkomste

Hoë presisie: Vervaardig met streng toleransies om akkurate werking in veeleisende toestande te verseker.

Kompakte ontwerp: Integreer verskeie komponente in 'n vaartbelynde pakket, spaar ruimte en gewig.

Duursaamheid en betroubaarheid: Gebou om strawwe omgewings te weerstaan en langtermyn stabiele werkverrigting te bied.

Geïntegreerde funksionaliteit: Kombineer verskeie funksies in een samestelling, kompleksiteit te verminder en doeltreffendheid te verbeter.

Aanpasbare opsies: Kan aangepas word om by spesifieke toepassingsbehoeftes te pas, insluitend materiaalkeuse, konfigurasie, en prestasie parameters.

Gemak van installasie: Ontwerp vir eenvoudige integrasie in bestaande stelsels, dikwels met plug-en-speel-vermoë.

Gevorderde materiaal: Gebruik die nuutste materiale vir verbeterde prestasie-eienskappe soos hittebestandheid, weerstand teen korrosie, en krag.

Voldoening aan Standaarde: Voldoen aan relevante internasionale en industrie-spesifieke standaarde vir veiligheid en werkverrigting.

Modulêre ontwerp: Fasiliteer maklike opgraderings en instandhouding, met komponente wat individueel vervang of bygewerk kan word.

Prestasie optimering: Geoptimaliseer vir energiedoeltreffendheid en werkverrigting, bydra tot verminderde bedryfskoste oor tyd.

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

Specification of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

High-standard industrial electrical wire ports, multicore ports, cords, cords, and wire assemblies are crafted to provide robust efficiency sought after atmospheres. These parts are crafted from premium materials, consisting of high-grade thermoplastics, steels, and corrosion-resistant alloys, ensuring longevity under severe conditions. The connectors feature a temperature level resistance series of -40 °C tot 120 °C, making them suitable for both indoor and outdoor applications. With IP67/IP68 access protection rankings, they are dustproof, water resistant, and immune to moisture, oils, and chemicals, ideal for rough commercial setups.

Electrically, these adapters support voltages approximately 1000V and existing scores of 30A per call, with reduced contact resistance (

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

Applications of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

High typical commercial electric cable connectors, multicore connectors, wires, cable televisions, and cable television settings up are critical components in contemporary industrial and commercial systems, ensuring reliable connectivity, power circulation, and signal transmission across requiring environments. These products are crafted to fulfill rigorous efficiency requirements, offering resilience, security, and resistance to severe conditions such as heats, vogtigheid, resonances, and chemical exposure. Their applications span varied industries, making it possible for seamless operations in complicated arrangements.

In production and automation, these adapters and cables are integral to equipment, robotika, and control systems. They promote specific signal transmission for sensing units, aktueerders, and programmable reasoning controllers (PLCs), making certain efficient assembly line. Multicore adapters streamline circuitry in compact spaces, lowering setup time while keeping robust links. Heavy-duty cable assemblies are utilized in electric motor drives, vervoerbandstelsels, en CNC-toerusting, where high current capability and abrasion resistance are essential.

The power industry counts on these elements for renewable resource systems, such as solar ranches and wind turbines, where weatherproof ports and UV-resistant cable televisions guarantee long life. In oil and gas, explosion-proof adapters and armored cables avoid dangers in unstable environments. Power distribution networks make use of high-voltage cable television settings up to maintain grid security.

Transport sectors, including automotive, lugvaart, and trains, rely on these services for engine control devices, avionics, and signaling systems. Heat-resistant and light-weight cords improve fuel efficiency and safety and security. Electric cars (EV's) utilize high-current connectors for battery administration and charging framework.

Telecom facilities uses multicore adapters and secured cable televisions to sustain high-speed information transmission in information centers and 5G networks. Medical devices utilizes sterilizable, high-precision adapters and wires for imaging systems, individual monitors, and surgical tools, guaranteeing conformity with rigorous hygiene standards.

In building and construction and facilities, these parts power clever buildings, a/c systems, and lights controls. Personalized cord assemblies adapt to unique task requirements, from underground electrical wiring to smart city applications.

Generally, high-standard commercial ports and cable televisions are necessary for modern innovation, using scalability, conformity with international certifications (bv., UL, OVK), and flexibility to advancing market demands. Their function in improving operational performance, safety and security, and connectivity makes them vital across international markets.

Maatskappy profiel

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) is een van die voorste ondernemings in kragelektronika-tegnologie en kragprodukte, wat ten volle betrokke is by die ontwikkeling van sonkrag-omsetters, transformators, spanning reguleerders, verspreidingskaste, tiristors, modules, diodes, verwarmers, en ander elektroniese toestelle of halfgeleiers. Ons sal daartoe verbind wees om gebruikers van hoë gehalte te voorsien, doeltreffende produkte en bedagsame diens.

Dit aanvaar betaling via kredietkaart, T/T, Wes Unie, en Paypal. PDDN sal die goedere aan kliënte oorsee stuur deur FedEx, DHL, deur die see, of per lug. If you want high-quality High standard industrial electrical wire connector multicore connector wires cables & cable assemblies, stuur asseblief vir ons navrae; ons sal hier wees om jou te help.

Betaalmetodes

L/C, T/T, Western Union, Paypal, Kredietkaart ens.

Versending

By see, deur die lug, deur uitdruklik, soos kliënte versoek.

Bergingsvoorwaardes

1) Berg in 'n droë omgewing by kamertemperatuur.

2) Vermy klam en hoë temperature.

3) Gebruik onmiddellik nadat die binneste paksak oopgemaak is.

5 FAQs of High standard industrial electrical wire connector multicore connector wires cables & cable assemblies

What are the primary applications of high-standard industrial multicore connectors and cable assemblies? High-standard industrial multicore connectors and cable assemblies are designed for demanding environments such as manufacturing plants, outomatisering stelsels, energy infrastructure, en swaar masjinerie. They ensure reliable power and signal transmission in harsh conditions, including exposure to extreme temperatures, vog, chemicals, and vibrations. Common uses include connecting control panels, motors, sensors, and robotics, where durability and precision are critical.

What materials are used in these connectors to ensure durability? These connectors are constructed from high-grade thermoplastics, metals, and engineered composites to withstand industrial stressors. Housing materials like polyamide or stainless steel offer resistance to corrosion, UV radiation, and impact. Internally, contacts are often gold-plated or tin-coated for optimal conductivity and oxidation resistance. Cable jackets use PVC, PUR, or TPE blends to protect against abrasion, oils, en temperatuurskommelings, langtermyn prestasie te verseker.

What voltage and temperature ratings do these connectors support? Industrial multicore connectors typically handle voltages up to 1000V AC/DC, with current ratings ranging from 5A to 250A, depending on the design. Temperature tolerance ranges from -40°C to +120°C, making them suitable for both freezing environments and high-heat applications like near engines or industrial ovens. Always verify the product’s specifications to match your operational requirements.

Can these connectors be customized for specific industrial needs? Ja, customization is common. Manufacturers offer tailored solutions for wire gauge, core count (2 aan 50+ kerne), length, shielding (braided or foil for EMI/RFI protection), and connector types (M12, M16, DIN, ens.). Colors, markings, and IP ratings (bv., IP67/IP68 for waterproofing) can also be adjusted to meet industry standards or project-specific demands.

How do I ensure proper installation and maintenance? Use crimping or soldering tools recommended by the manufacturer for secure terminations. Follow torque specifications when tightening screws to avoid damage. Regularly inspect connectors for wear, korrosie, or loose connections, and clean them with non-abrasive solvents. For cable assemblies, avoid sharp bends and ensure strain relief is properly secured. Adhering to these practices minimizes downtime and extends product lifespan.

(High standard industrial electrical wire connector multicore connector wires cables & cable assemblies)

AANVRA 'N KWOTATIE

VERWANTE PRODUKTE

SJC Factory Whole Headlights vir BMW 3 Reeks E92 E93 2006-2010 koplampe samestelling gewysigde LED Angel Eye lens koplig

Auto Spare Parts Truck/Trailer/Tractor Brake Shoe Kits & Assemblies for DAF/SAF/RENAULT Brake liner kits & Assemblies

Car Engine C6 2.0T CDL Complete Auto Engine Systems Assembly for TT/ A4/ Scirocco/Avant D/Audi A4/S4

N20 N55 N54 B48 B58 Engine Assembly Motor for F35 F02 F18 G38 G12 E71 2.0L 3.0L turbo enginey before 2021

Outo-enjinsamestelling 1.8T CJE R4 volledige enjin vir Audi A4 B8 A5 8T